Strippit "S" & "M" Series

Workclamps & Repair Parts

In 1989, Strippit Finally got around to Upgrading their Workclamp Designs.

The Old Pivoting-Type that Strippit had used since 1970 was an Ancient Copy of 1960's Wiedemann Workclamps. Problem with this Type of Workclamp was that Gripping-Jaws Traveled in a Arc as Clamp Moved Up & Down,

so Gripped Work-Sheet was Never Parallel to Support-Tables or Punch Dies,

which Lead to Tooling Punch-Marks on Parts, or even Part Jam-Ups in Turret.

New S & M Workclamps were Similar to Amada Design, in that Clamp-Body was in Bearing-Guides allowing it to Move Straight Up & Down, keeping Workclamp & Gripped-Worksheet Parallel to Support Tables & Tooling, leading to Higher Quality Parts with Better Accuracy, Less Marking, & Less Jams-Ups.

These are Very Good Workclamps.

But Problem with these New Types of Workclamps is that Strippit Made

Endless Variations of Same Basic Design! And Strippit Shipped the Same

Model Machines with Different Workclamps at Different times.

So, No One is Ever-Sure of Which Version was Put on Your Machine when it

was Built, or which are Correct Parts to Repair Your Workclamps!

Some Types of Workclamps that Strippit Made;

--- Inch Versions

--- Metric Versions

--- Versions with Both Inch & Metric Parts!

--- Standard Versions

--- Programmable Versions for the Left-Side

--- Programmable Versions for the Right-Side

Very Confusing for Everyone.

This S-Type of Workclamp was used on the Following Machines;

--- 1000S

--- 1000SX

--- 1000SXP

--- 1000SXP/30

--- 1250S

--- 1250SX

--- 1250SXP

--- 1250SXP/30

--- 1250M

--- 1250MXP/30

--- 1250MH

--- 1250MH/30

as well as Other Machine Model Variations.

Most of Strippit's 30-Ton Machines are a Variant of S & M Type Workclamp.

Most of Strippit's 20-Ton Machines use the Cheaper R-Type Workclamp.

This page was last updated: February 10, 2023

Common Repair Parts;

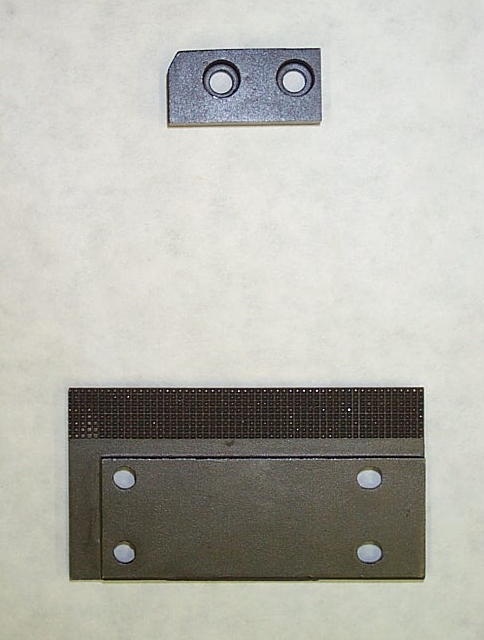

Item #22

#119903-000 Gage Block

Uses 2 Item #21

Inch or Metric Screws

Item #23 Lower-Jaw

#119902-000

and

#119902-300

Both Part Numbers have

been used, Same Part!

Don't forget to Order 4

Item #18 Inch or Metric Screws for Each

Lower Jaw

Item #24

#119899-000

Upper-Jaw

These are Our

Heavy-Duty

Type with

2 Carbide-Teeth

for 3-Times

Holding-Power

of Original

Knife-Edge Type!

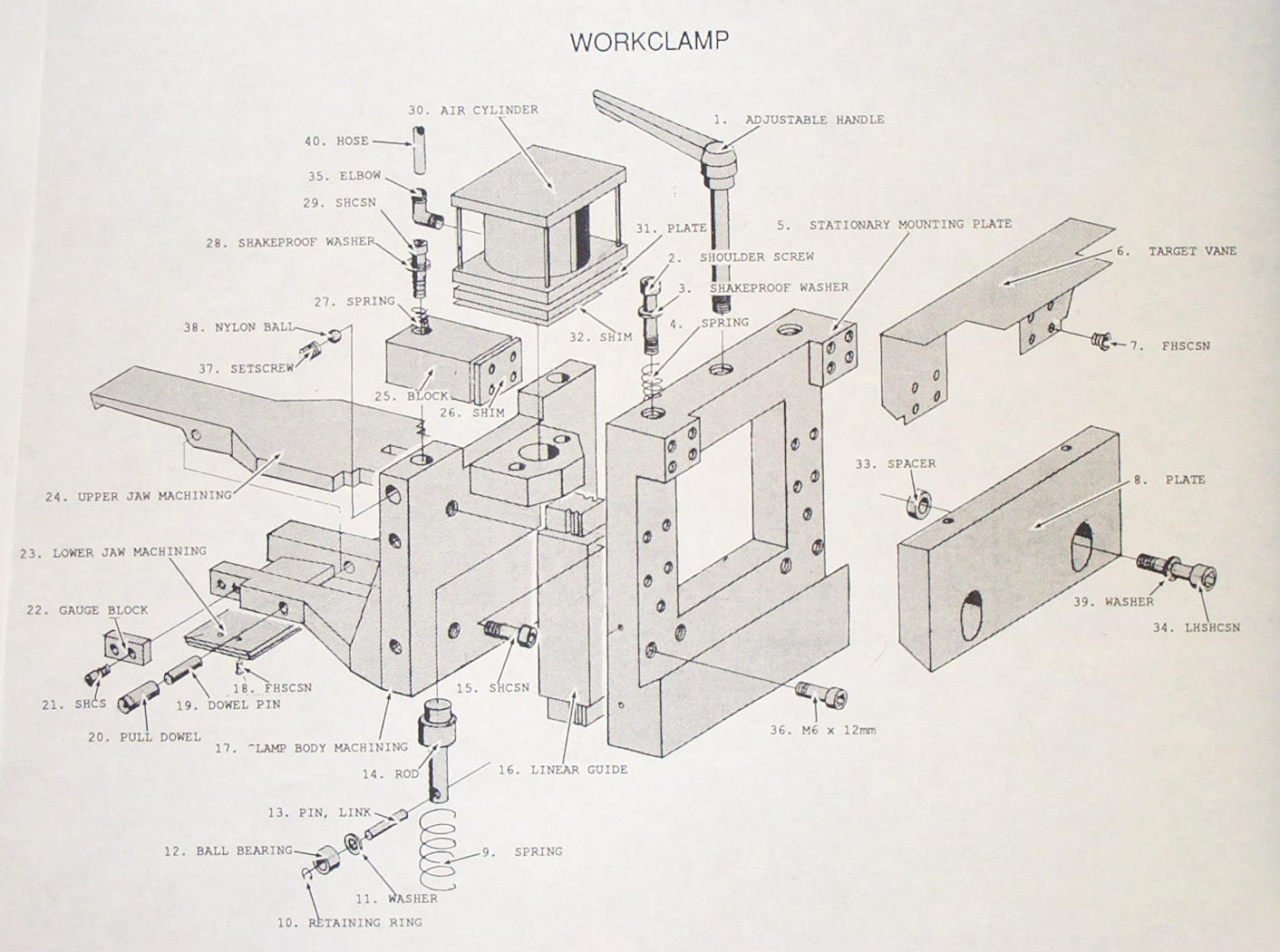

2 Views of Programmable

S & M Type Workclamps

Note Clamping

Air Cylinder on Top

Below is Diagram of a Typical

Standard S & M Type Workclamp

We Can Supply

New Workclamp Assemblies

The No-Punch Zone Vanes are Unbolted and Transferred from your Old Workclamps to New Workclamps.

If you have

Programmable-Workclamps

(Instead of Manual Handles)

the Air-Clamping Mechanism is also Moved from Old Workclamps to

New Workclamps.

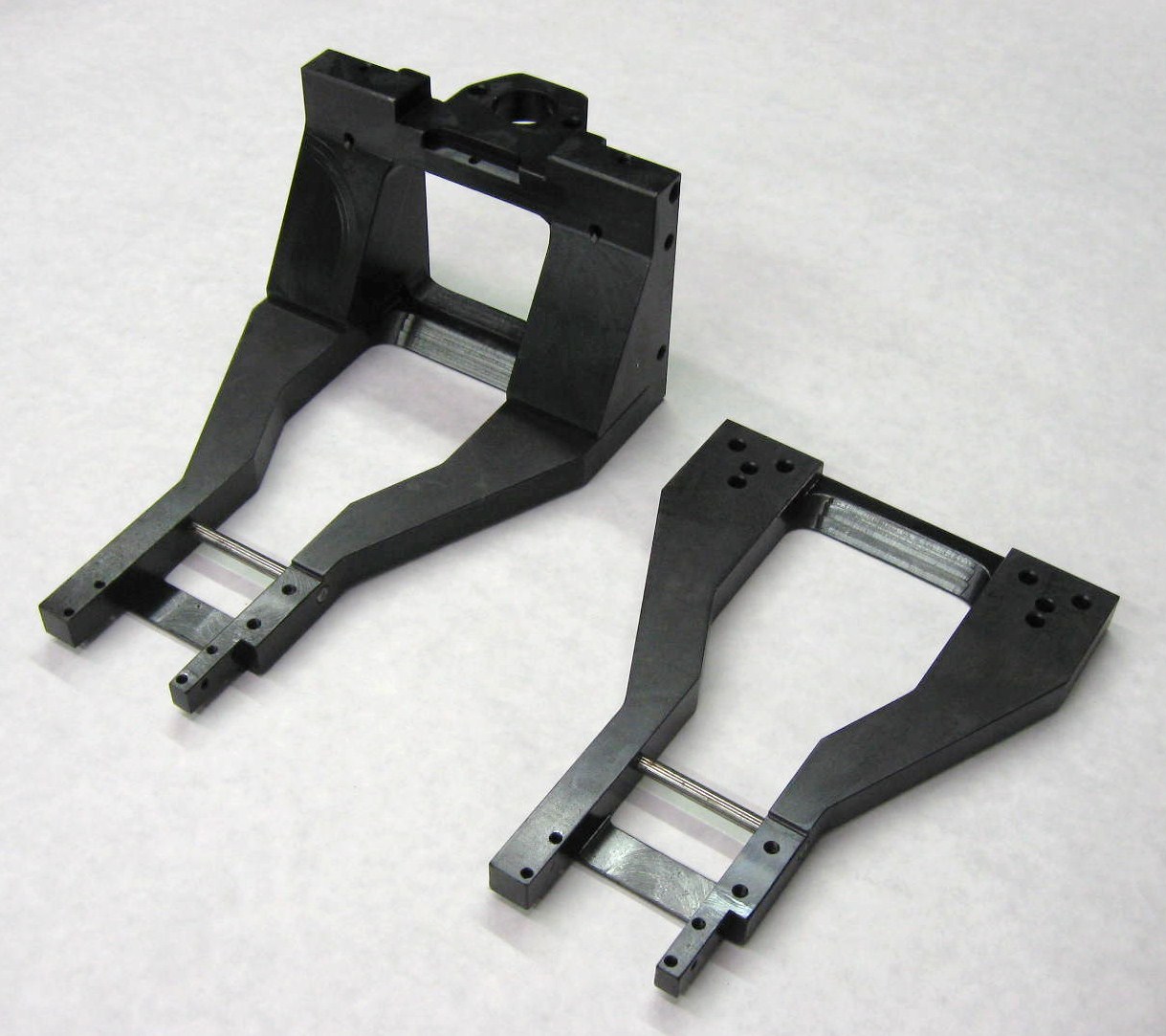

2 Photos show Front and Side View of our New Workclamps.

Note Also, Unlike Strippit, Our Clamp Body is a 2-Piece Assembly. So if you Damage Front-Bottom Part, it can be Replaced without Replacing the Top-Back Part.

Much Easier to Replace as you Replace HALF the Clamp Body

and Save HALF the Money!

With Strippit, you have to Replace the Complete 1-Piece Body.

Above-LEFT is our 2-Piece S & M Type Workclamp Body Assembly.

If it is ever Damaged, Just Replace the Front-Bottom Piece,

Shown on the RIGHT-Above, Much Easier and for Half the Money of a Complete Body!

Unfortunately, Strippit Foolishly has made 3-Different Versions of Workclamp Bodies.

To find-out Which Version You need,

You Measure 1 Bolt Item #15 that Bolts Item #16 Linear Guide Bearing to your

Old Item #17 "Clamp Body Machining" which we just call the Workclamp Body.

This is Not that hard to do, and will only take about 10 minutes.

1 -- Remove a Workclamp from your Machine.

2 -- Remove 2 Item #34 Bolts and Item #8 Clamp Plate from backside of Workclamp

3 -- Remove 2 Item #29 Bolts and Item #27 Spring from Item #25 Blocks

4 -- Remove 8 Item #36 1/4"-20 or 6mm Bolts from Item #5 Stationary Plate

5 -- Separate Workclamp into 2 Pieces for access to Item #16 Linear Guide Bearing

6 -- Remove any 1 of the 4 Item #15 Bolts through Item #16 Linear Guide Bearing

Measure Bolt Size, it will be 1 of the following 3 Sizes;

1/4" (about .250") Mainly used 1989 to 1995 Order Clamp Body Inch-Type

6mm (about .236") Mainly used 1995 to 2000 Order Clamp Body 6mm-Type

5mm (about .197") Rare, Sometimes used 1999+ Order Clamp Body 5mm-Type

Please Note!!!

All of Strippit's Early Workclamps used Inch-Threads

on All Bolts & Screws & Tapped-Holes.

Later-On about 1995, Strippit Gradually Switched-Over to Metric System,

and Now All Original Equipment Strippit Workclamps use only

Metric-Threads on All Bolts & Screws & Tapped-Holes.

Most Workclamps Parts that We, Machine Technologies Co. Furnish,

will have Inch-Threads on All Bolts & Screws & Tapped-Holes,

with Exception of S & M Metric Clamp Body 6mm-Type & 5mm-Type.

View of

Standard

Strippit

S & M Type Workclamps

Below is Some of Workclamp Repair Parts We Stock

Below is Our Replacement 2-Piece Workclamp Body

S & M Workclamp Air Cylinder

Strippit S & M Type Workclamp Air Cylinder are Item #30 and

Part #803240-000

And remember to get

Item #35 Part #17442-000

Air Fittings

Note! If you Bought a

New Complete S & M Type

Workclamp Assembly from

Machine Technologies,

We Used Different Air Cyclinder!

For Machine Technologies

S & M Workclamps, (Not Strippit)

Use Item #30 and

Part #803240-MOD

Email a Photo is Best!