Strippit vs Amada

Advice, Facts, History, Gossip, Rants & Raves,

and CNC Punch-Machine Brand Comparisons.

I hear manyComplaints about Machines built with Hydraulic Rams. All Manufactures have gone to Hydraulic Rams and Quit making Mechanical (Flywheel & Crankshaft) Rams. Manufactures Think its Easier & Cheaper to Build them (I Don't Think it's Really True), and Marketing & Sales use Theoretical Great New Features to Sell New Machines (The "Sizzle" , The Real Reason). Features like Controlling

Ram-Stroke for Die Penetration, Louver Adjustments, Marking & Stamping, Shear & Rib Tools, Low Tool Hover-Height for Faster Punching, Etc. It Does Sound Great!

Problem is, there are Questions about it Working Correctly As Advertised, and Worse, it may Not Even Be Technically Possible to Work Correctly at All! Hydraulics work just fine in Press Brakes at only 10 Strokes a Minute or so. But CNC Punch Press Manufactures Proudly Advertise 400 to 600 Hits per Minute and Even Faster! At Full Speed, it seems they Can Not Accurately Control Hydraulic-Ram Position, which Negates All Advantages over a Mechanical Ram. Do the Math. Some Manufactures Advertise 500 Hits Per Minute and More. So they are making a X & Y Axis Move AND a Full Power Punch Down-Stroke AND a Up-Stroke in 120 Milliseconds! Finn-Power Says some of their Machines Nibble at 1100 Hits a Minute, that's Only 54 Milliseconds for the X & Y Axis Move AND Down Punch Stroke AND Up Nibble Punch Stroke!

So, How much Time is Actually Spent in the Punch Stroke? Do You Think it's "Under Control"? I Don't.

In My (and Other's) Opinion, it's Laughable to Think you can Really Read Position-Data off the Ram Encoder, Send & Process that Data in Your CNC Control, Have CNC Adjust your Electro-Mechanical Hydraulic Valves, and Maintain Position-Control on that Fast-Moving Punch-Ram (Some Pesky Laws of Physics are Involved) to a Accuracy of a Thousands of a Inch, Over & Over Again,

All in Real Time While it's Actually Moving Up & Down and Punching Metal at that Hi-Speed.

Result is Ram and your Punch Tool are Not where it "Should Be" & Where CNC Control "Thinks" It Is.

Sometimes Position Errors Accumulate until something Bad Happens. Result is Poor Hole Position Accuracy, Poor Hole Quality, Broken Punch & Die Tools, Ripped & Crumpled Sheet Metal Parts, Machine Breakage, Lots of Machine "Down Time", Etc.. Manufacture's Blame it on Customer's "Bad Tooling" (Very Popular), Poor Tool Maintenance (Also Popular), Poor Machine Maintenance, Poor Operators, Poor Programming Practices, Etc., Etc., --- Anything but Manufacture's Machine.

These Types of Rams seem to Wear-Out Quickly, Blow-Out Seals, and Leak Hydraulic Oil all the time.

They are Usually Difficult and Very Expensive to Repair. Manufactures "Get Away" with this because:

--- Most Shops don't use Special Features & Special Tools that were used to Sell the Machine.

--- Most Shops don't Even Recognize where Problems are Really Coming from.

--- Most Shops think these are just Standard Problems & Just Tolerate it as "Normal".

--- Manufactures "Help-Out" by Advising Customer's to "Slow Down The Ram Speed", and Various Programming Tricks like Dwelling at Top or Bottom of Punch Stroke, Dwelling Before & After Punch Stroke, Slowing Down X & Y Axis Speed, and even Doing a Full-Upstroke (from Low Hover-Height) every Few Hits "Just To Re-Calibrate Ram". Why the Hell do you have to "Recalibrate" if CNC Control "Knows" Where Punch-Ram is? There is at least 1 Law Suit over these Problems & Losses they caused.

Early 2007, Update on the Law Suit.

I've followed this Law Suit for Several Years, Here's Story as I know it. You can Believe What You Wish.

A Customer Said there was Machine Defect & Sued Strippit. Strippit Said there was No Machine Defect.

Suit Centered on Whether or Not Strippit Machines in Question, Late 1990's Vintage Hydraulic-Ram

Machines with P.C. Computer Controls, could in Fact Control their Punch-Ram, and there for,

it's Punching Tools. It was Alleged that Machine & Control Could Not Control Ram Position.

This Caused Both Long Punch-Strokes and Short Punch-Strokes with No Consistency at all.

Those of you who Know Anything about Punching, can Imagine the Many Problems this would Cause.

Long-Strokes could "Blow-Up" Punch Tool as it Bottoms-Out, and of course would Jam & Ruin Piece-Part Sheet, and maybe Damage Sensors & Workclamps. Imagine what it would do to a $3000 Louver Tool, Wilson-Wheel Tools, Stamp-Tools, or other Special-Tooling where Depth Must Be Controlled.

Short-Strokes would leave Punch Slug Half in the Die, and Half in the Partially Punched Hole.

X & Y & T & C Axis would then make the Next Move, Ripping & Jamming & Ruining Piece-Part Sheet,

Breaking Various Machine Parts & Sensors and Workclamps, depending on Direction of next Axis Move.

Story Continues as Strippit Drags-Out Suit for Years Hoping Their Customer would Go Bankrupt or Give-Up Suit from Huge Legal Fees Incurred. This Didn't Happen. Eventually, Before Trial, Strippit Employees were Deposed and Admitted that there was Indeed Problems with Ram-Control on these Machines. At this Point, The Game is Over for Strippit. Strippit Settled with Customer. In This Settlement, In Our Unique American "Justice" System, Nobody Admits any Guilt or Fault or Fraud or Problems, Money Changed Hands, Secrecy & Non-Disclosure Agreements were Signed, All Suit Documents were Shredded, Now Nobody "Knows Nothing", and The Suit "Never Existed"!

But if You are Really Interested, Start your Discovery Search at the Erie County, NY Court Records Office.

My Opinion is there were Problems with Hydraulic Rams of That Era (1996-2001) that May or May-Not have been as Bad as Alleged. Strippit has Changed Venders and Improved Hydraulics & Rams & Controls since then. I also think that Strippit was Not the only Manufacture with Hydraulic Ram Problems.

Some Manufactures, Like Trumpf, have Always-Used Hydraulic Press Drives and theirs seem to work well. Others Like Strippit, were on a Learning-Curve in 1990's & Early 2000's and have Gone-Through about

4 Generations of Hydraulics Figuring it all out. Strippit's Later Machines (about 2002 & Up) seem to Work Well, but many Reports of Ram-Problems onl their Earlier (Pre-2002) Hydraulic Machines.

I Obviously Prefer Mechanical Press Drives, but You Need to Investigate & Form Your Own Opinion!

Another Dirty Secret Manufactures Forget to Tell You About is Very High Electricity Usage of their Hydraulic Machines. They use 4 to 8 Times Electricity of a Mechanical Press Drive and that Expensive Wasted Electricity is Spewed-Out of the Heat-Exchanger into your Shop. Where Did You Think Energy came from, for All that Heat? A Typical Classic Mechanical Press Drive used a 3 to 8 HP Motor that Turned a Flywheel. Once Flywheel was up to Proper Speed, Motor just Coasts-Along, and only draws Minimum Power to keep it at that Speed. When you Punch, Stored Energy is used from Flywheel, Motor Briefly Draws a Burst of Electrical Power to get Flywheel back up to Speed, then it Coasts at Minimum Power again, until you Punch again. If Machine is On, but Not Punching, it Draws Very Little Power. Very Efficient!

Hydraulic Press Machines Typically have a Huge 25 to 40 HP Power-Pack sitting next to Machine.

These Hydraulic Power-Packs Run Wide-Open All The Time (No Coasting) as they Must have Full Hydraulic Pressure Available All The Time as they wait for a Punch Request from Machine. Even if you are Not Punching, if Machine is On, Hydraulic Pack is Running Wide Open, and Drawing Full Electrical Power All The Time. All that Wasted Electricity is Turned to Heat, and if Manufacture Cut-Corners and put Too-Small of a Radiator on Power Pack (Very Common), Hydraulics Will eventually Overheat, and Cause Odd Intermittent Punching Problems, or even Shut-Down Machine. Very Very Inefficient!

Recently a couple of Manufacturers (Muratec, Amada, Finn-Power) have come out with a Interesting New Concept. They take a Large Servo Drive (Which Can be Very Accurately Controlled) similar to Large Y-Axis Drive on your CNC Machine, and Coupling it with Toggle-Linkage or Geared-Crankshaft to Punch Ram. No Pneumatic or Hydraulic Problems, Saves Lots of Electricity, and lets them Gain Complete Position &

Speed-Profile Control over the Ram. It Sounds Good. It will be Interesting to see how it Develops, and if it Solves some of above mentioned Hydraulic Ram Control Problems. Check Them Out!

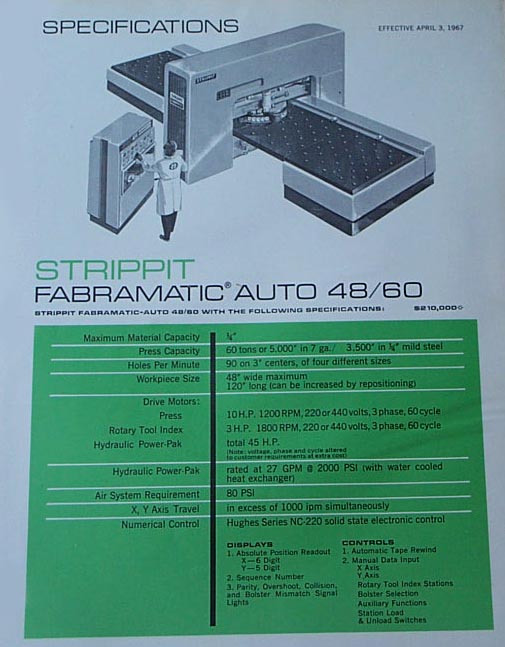

A Rare Copy of Strippit's Brochure on their

Bridge-Frame FM48/60 Machine Dated April 3, 1967!

This is 7 years Before Amada's Machine & 4 Years

Before Amada even Incorporated their U.S. division!

But Strippit Management was Too Short-Sighted to embrace Bridge-Frame Machine Concept,

"Too Expensive" they said, and only a couple Machines were build.

Dandy Don (My Service Manager, R.I.P.) & Other

Sources told me the Strippit Engineer who Designed

Bridge-Frame, left & went to work for Amada, takeing

Concept there when Strippit would not use his

Design anymore. To their Credit, Amada did

Embrace this Superior Frame Concept, and was

one of their Advantages for many years.

How Ironic that

Strippit Designed Amada's Bridge Frame!

I saw Machine Still Running in N.Y. City & another in Texas in early 1980's, in their 3rd Decade! It's a Shame it took Strippit 30 years to Re-incorporate Bridge-Frame Concept (Which They Invented!)

into their Machines in late 1990's.

Another example is Amada's False Claim to be "First" in Sheet Metal Laser Machines. Again Not True!

Above is picture of Strippit's First, and Industry's First, Sheet Metal Laser Cutting Machine,

Patent #EP0008773 A1. This Punch & Laser Combination Machine was Shipped to

Lyons Metal Products, Hamilton, Ontario, Canada, back in 1978, Many Years Before Anyone Else!

Strippit & Houdaille Electronics was also Early Inventer of CNC Technology Patent #US4150427A.

Some Faults & Pluses with Strippit; But Once Again, Strippit & Houdaille Management Pulled Defeat

Out of Jaws of Victory! This is Strippit's Chronic Problem, Good Engineering, Good Manufacturing,

But Greedy Self-Enriching & Clueless and even Stupid Top Management.

Though Strippit had Many Years Head-Start in Laser Cutting Business, they Squandered their Huge Lead.

In early 1980's when Industry moved toward easy to use Flat-Bed Lasers with more features, Strippit offered Same Tired Old FC1230/30/1500 Punch Machine, 1st shipped in 1978, with Punch-Hardware Removed & a Laser-Head Bolted-On called "Laser Center" and Wondered why they only Sold 6 Machines.

Reality-Was, "Managers" of Houdaille Industries / Ken Slawson / Strippit-Div. / KKR Buy-Out-Boys

/ Idex Inc. / Strippit-Inc. / LVD Corp. / Etc. were All So-Busy Buying & Selling each other Back & Forth, Doing "Stock Buy-Outs", "Going-Private", "Going Public", Re-Selling Stock, Buying & Selling & Closing Companies, "Laying-Off" Long-Term Employees, Managing "Cash-Flow", Paying-Off Their Buy-Out Loans,

and Making Each-Other Millionaires, That they had No-Time or Inclination for Properly Investing-In &

Running Their Pesky Little Cash-Cow Machine Tool Companies. And, They Certainly Didn't.

One Executive at Strippit Bragged "I have a MBA degree, I Can Run Any Company, I Don't Need to Know Anything about Machine Tools". What an Ass. I Think Car Companies Need to be run by Car Guys,

and Machine Tool Companies Need to be run by Machine Tool Guys. Strippit was run by Houdaille & Idex Executives and their Bean-Counters, and when business was bad, they Blamed Japan, Economy, Congress, Reagan Administration, Weather, Etc. Everything & Everyone But Themselves! Results of their "Executive Decisions" are Self-Evident.

KKR & Houdaille Industries & Ken Slawson Closed Burgmaster CNC Machining-Center Plant

in Gardena, CA. where it had been for almost a Half-Century.

The Di-Acro Saga. KKR & Ken Slawson & Houdaille Industries Closed Di-Acro Facility in Lake City, MN., where it had been a Half-Century. Houdaille Palmed-Off Di-Acro's lines to Strippit where it was Unwelcome.

Strippit was Forced to make Crappy Di-Acro CAP1000 Punch Machines and sell them as "Entry Level" Strippits. CAP Machines were Obsolete (based on Old 1970's Di-Acro VT-36 Machines), Light-Duty

(Breaks Rams & Crankshafts if you Punch Heavy-Material) and were considered "Junk", compared to "Real" Strippits. Strippit Stopped making CAP's as soon as they could, and CAP's are now "Orphans", with No Parts & Service Available. Avoid CAP1000 and CAP1250 Machines!

Strippit was also Forced to make Di-Acro Press Brakes. This could have been a Good Thing, as Di-Acro Line of Hydra-Mechanical Brakes were Popular and had a Good Reputation as they were Accurate, Reliable, Easy to Use, and Relatively Inexpensive. But Strippit Management Struck Again! They had Bright-Idea of

making Brakes in Taiwan, then Import & Re-Paint Them, and make Lots of Money! Except, Quality was

So-Bad when they Came-In Strippit had to Completely Disassemble Each Machine and Rebuild it from Ground-Up before they could Sell Them. So, they Sold-Off Brake-Line to Pacific Press Co., where they made them under "Tri-Acro" Name for a few years, before Pacific finally Killed-Off Great Old

Di-Acro / Tri-Acro Hydra-Mechanical Brake Line for Good. Another Orphan.

I Keep Getting Calls Looking for Di-Acro Co. There Is No Di-Acro Company! Real Di-Acro Factory Was Closed Over 40 Years ago in 1983! There are NO Di-Acro CNC Repair Parts, NO Di-Acro Repair Service, NO Di-Acro Prints, Manuals, or Information. You have to Figure Out Problems Yourself, Make Repair-Parts, & Fix it Yourself. Or Buy a New Replacement Machine.

Di-Acro Manual Punch & Bender Lines were Sold-Off to a Small (Garage Shop) Company in Ohio,

that had Rights to Di-Acro Name. This Company has Now Closed.

Update Summer 2006. A Quarter-Century after Di-Acro Closed, Things Go Full-Circle. Company in Ohio had Auction and a Group from Defunct Original Di-Acro Co. bought Remnants of Di-Acro. They Restarted

Some of Di-Acro Manual (Hand) Machine Lines back in their Original Home in Lake City, MN.

So, there have been 5 Di-Acro Companies! Original in Lake City, Di-Acro at Strippit, Di-Acro (Tri-Acro) at Pacific, Di-Acro in Ohio, and now Di-Acro at Acrotech Co. I Wish them Well & Hope they Expand.

But there is No Parts or Service Support for Old Di-Acro CNC Turret-Punches & Power Press-Brake Lines.

If anyone Knows of Di-Acro CNC Turret & Brake Parts & Service, let me know.

Note, But if You have a Di-Acro CNC Turret or CNC Burgmaster that uses General Electric Servos,

This page was last updated: February 9, 2023

I, as an Ex-Strippit Service & Tech-Support Escapee, Had a Very Positive Bias towards Strippit,

though I have now Lost This Bias from LVD Strippit's Bad Attitudes & "Staff-Policies".

The Fabrication Industry Is Full Of Ex-Strippit Alumni. The Standing Joke at Machine Tool Shows is

How LVD Strippit Trains Good People for the Rest of the Machine Tool Industry to Hire & Use.

For Your Punching-Pleasure, Here are Some of the Manufactures of CNC Punch-Presses.

Note, Some of these Companies No Longer Even Exist! Amada, Behrens, Boschert, Comeq, Danobat, Di-Acro, Durma, Euromac, Ermak, Ficep, Finn-Power, Gasparini, Haco, Hindustan Hydraulics, ITEK, LVD, Muratec, Nisshinbo, Pierce-All, Pivatic, Pullmax, Raskins, Rainer, Salvagnini, Shape, Strippit, Tailift, Technology Italiana, Trumpf, Wiedemann, Whitney, Yawei.

Punch-Tooling Punch-Tooling Punch-Tooling Punch-Tooling

Since you can NO Longer Buy "Strippit-Tooling" From Strippit,

Here are the U.S. Sources of "Strippit-Tooling", or as it is Now Known,

"Thin-Turret" or "Thin-Turret Fab." Tooling.

Click-On The 6 Tooling Web-Links Below for More Information;

When Considering a Machine Purchase, Ask about Service and Tech-Support Sellers & Manufactures provide. How Big is Service Dept.? How many Machines and Territory do they Cover? What is Response Time? Do they have a Factory-Trained Serviceman Local, or do You Pay to Fly-In a Guy Every Time you need Service? Do they have Phone Support? What are their Hours? Do they Charge Extra for it? Is it Any Good? Even if its Free, if its Not Any Good, its Worthless! Do they Stock Mechanical and Electronic Parts? Where? Do they Provide Complete Service, or does a 3rd Party provide CNC Control Service which can lead to Finger-Pointing between Machine Manufacturer and CNC Control Manufacturer. Ask for Customer List you can Call to see how they like their Machine Purchase and Service & Support.

You are the One Writing the Big Check! Ask The Tough Questions Before You Buy, Not After!!!

Move-On to Another Machine Brand if you Don't like the Answers you get!!!

Management Hates to spend Money on providing Really Good Service and it's First thing they Cut when times get bad. The Saying goes "Sales Dept. Provides 1st Machine Sale at a Customer, but Service Sells 2nd and 3rd", which is Actually True! But Management Never puts their Money where their Mouth is, and Considers Service a "Cost", not a "Profit" Center at their Companies, and cut it every change they get.

This Very Directly Affects You & Your Business!

How Selling Field Service to Your Customer's at 3+ Dollars A Minute can be a "Cost" is Beyond Me!!!

I would Expand Field Service & Provide Good Customer Tech-Support (Now, There's a Novelty), Which would also Help Boost Machine Sales, and Try Not to Laugh on the Way to the Bank. I Charge Much Less than Manufactures (Yes, My Overhead is Lower) and Can Happily Embellish on This

"Service & Support Subject" at length at my Beach House on TopSail Island. You Bring The Margaritas!

And So, Strippit & Houdaille & KKR & Idex & LVD MBA--Management

Rocket-Scientists Gave-Up All Of Strippit's Market Leadership Positions In

CNC Punch-Machines

& S.A.F. Punch Machines

& F.M.S. Systems

& Laser-Machines

& "Strippit"-Tooling

& Unitized-Tooling

& Hydra Springs

& CNC-Controls

& Press-Brakes

What The Hell Were They Thinking???

More Importantly, What Are They Thinking & And Where Are They Going Now?

LVD-Strippit can still Make Excellent Turret Punch Machines , which

are Fast & Accurate (20 Year Old Strippit's are Still Faster than New Amada's).

But Strippit is Just NOT the Dominant Industry Force that they Once Were, and

Still Could Be Today! Corrections on Facts, History, and Opinions are Invited!

And I will Update this Page from Time to Time, as It's Really a Lot of Fun!

Machine Technologies Specialty Is the

HECC80 CNC Control Strippit Turret Machines Built in 1975 to 1988

Much Has Been Said About

"Which Is Better, Strippit or Amada Punch Machines?"

The Fact-Is, Electronic & Mechanical Technologies have Advanced So-Much, that CNC Punch Machines

are a Relatively Stable & Mature Technology, and All Manufactures make a Good Product.

What is Most Important, Is the Level of Factory Technical Support, Field Repair Service Availability,

Expertise Level, and Repair Parts Availability! Now, a Year, 5 Years, and 10 Years After the Sale!

I have seen Many Imports (And U.S.-Made Machines Too!) become "Orphans" after a Few Short Years with No Support at All! You Will have to Live with Your Decision for Many Years!

All Machines And Controls Break! If You Can Not Get It Fixed, It Is Not Worth Anything! In this regard,

it would seem Larger Players, such as LVD-Strippit, Amada, or Trumpf would be the way to go over

some smaller players, that do not have a large enough customer base to maintain a proper

Service & Parts Organization. This, of course, Varies Greatly by Country and Region.

You Need to find out what Parts & Service Support is Available where You Are, Before You Buy, Not After!

In my 45 Plus Years in CNC Punch Industry, I have heard Customer's Stories on Every Brand of Machine Tool. Every Manufacturer has Customer's that Love them and Customer's that Hate them. Problems are Not-Always caused by Manufactures. Many Shops are their Own Worse Enemy because they Don't Follow

Manufacturers Recommended Practices & Procedures. Talk to as many people as you can, and

beware of Salesmen's claims, if not Lying, often Stretch The-Truth. Because to eat, they must Sell

what they have, which is not necessarily what you need. One Used-Machinery Salesman told me

"The Best Machine for a Customer is Whatever Machine I have in my Warehouse!" I Do Not Agree!

You Need To Do Your Own Homework!

Talk to Machine Operators, Programmers, Shop Owners, Tool Salesmen, Machine Servicemen. Visit Machine Shows, Visit other Shops, Read "The Fabricator", "MetalForming", and Other Magazines. Then

Form Your Own Opinion on Your Specific Needs! Click-On Web-Links Below, They are a Great Resource!

Hydraulic vs Mechanical Rams

Summation

As this Web-Page Rambles-On Way More than was Originally Intended, Let me Try to Sum-Up the

"What Machine To Buy" Question. These are My (and Much Input from Fellow Servicemen & Salesmen & End-Users) Opinions Only, But are Based on 5-Decades of Wide-Experience in the CNC Punch Business. You Decide if I know what I am Talking About. Some of My Experience Credentials Are;

1 --- Strippit Factory Senior Serviceman, and have worked in Strippit's Machine Building "Pit".

2 --- Started Strippit "Tech Support" Interfacing with Service & Engineering on Difficult Problems.

3 --- Wrote In-House Service-Newsletters, Servo-Manuals, and Taught a Servo-Drive School at Strippit.

4 --- Independent Electronic & Mechanical Service Provider as Machine Technologies Co.

5 --- Independent Buyer & Seller of Used Strippit Machines at Machine Technologies Co.

6 --- Spent Time with LVD Factory in Belgium, and with Trump Factories in Germany & Switzerland,

and Toured European Job-Shops to Gain New Perspectives on Manufacturing.

7 --- Buyer & User of New CNC Punches as Half-Owner of 60-Man 8-Million a Year Sheetmetal Job Shop.

8 --- I Am Not a "Rocket-Scientist" but, Before My Strippit Days, I Did Work at Westinghouse Aerospace

(now Boeing) Troubleshooting E-3 AWACS Electronics Systems. Take a Look at;

For Those who have Not-Yet had their 2nd Cup of Coffee,

The Subtitles Here Are,

"Yes, There Is Money In Parts &Service"

and Sooooooooo......

Why Don't Manufactures Embrace It?

Click-On Photos for More TopSail Island Info!

--- Some of my Customer's have Amada's with Fanuc Controls built in the mid-1980's,

and could Not Get Parts to Fix their Controls ( Parts & Service, Remember? ).

Amada Made them get a New Fanuc Control Retrofitted to their Machine at a Cost of over $80,000!

Strippit Service & Parts, while Certainly Not the best on Older Machines, is still Sort-Of Available on Machines built in the 1980's & late 1970's. But, Their Knowledge on HECC80's is Fading Fast though.

--- Amada Top Turret Tool-Stations

Are Just Bored, Not Bushed. When (Not If!)

Stations become Worn and Scarred,

That Tool Station Becomes Worthless!

There are some Service Companies that have offered Mickey-Mouse Repairs

(Plastic-Strip Liners, etc.), But,

Stations Can Not Really Be Fixed!

Up-Date; API Co. has a Steel Bushing Fix,

using a Contractor, but is Very Expensive.

All Strippit Turrets have Hardened-Bushings which can be Easily Replaced to make that

Turret-Station like New again.

Some Faults & Pluses with Amada;

Amada has much to Admire. They make good solid & reliable Machines. They Used to have a large Service Organization, though it has Shrunk Greatly from Many Service Lay-Offs, as Amada Also seems to have Fallen on Hard Financial Times and has Cut Back on Service & Support Personal.

In their Heyday, Strippit had 450 Union Machine & Tool Workers & 600+ Employees. At their Low, it Dropped to about 38!!! A Fascinating Read on Fall of Burgmaster, Strippit, Di-Acro & Other Houdaille (Pronounced 'Who-Dye') Companies (And Problems with American Machine Tool Industry) is Featured in Harvard Business School Press's Book "When The Machine Stopped" by Max Holland.

Houdaille and Strippit were a Case-Study on How Not-To Run a Company. It Is Well Worth Reading !!!

Max Should Do A Up-Dated Edition! You Can See Strippit and Rest of Machine Tool Industry, Repeating

The Same Old Mistakes Again! Just Substitute China for Japan in The Book. It's That Old "Those Who Cannot Learn From History Are Doomed To Repeat It" Thing! Maybe They Should Read The Book!

"Not Only the Wealth,

But the Independence

And Security of a Country

Appear to be Materially Connected

With The Prosperity of Manufactures"

Alexander Hamilton,

1791, First U.S. Secretary of the Treasury

Mr. Hamilton Understood, but Someone

Please Read It Slowly To Bush & Trump

Mr. Education Brags "I Don't Read Books!"

and Trump Can't Read & is Far-Worse

than Bush ever was

and is just a Crime-Family "Griffter"

Strippit Management Did However, Waste 2 Years of their Best Mechanical & Electronic Engineers Time (and 2 Million Dollars) Developing in Secret "The Robot" back in 1982 to 1984 era. Industry Pundits of that time thought that "Robots" would be Next "Big Thing". Pundits Are Always Wrong! I Saw Robot Run. It was Bigger, Faster, and Lifted More than Anything on Market at that time. Very Cool Toy. But Market Never took off for Robots, back then. New Houdaille Division that would have been created, never happened. Strippit / Houdaille tried to sell technology, but no takers. I believe it was eventually sold for a Dollar, so Bean-Counters could make Money on it as a Tax Deduction. Few now Know it Ever Existed.

Next, Strippit Wasted Millions of Dollars & Years trying to develop "FMS Systems" (Flexible Manufacturing Systems -- Load / Punch / Shear / Stacking Cells), which Also Never Took Off. Strippit was Early Leader in FMS, but Shortsighted Management lost Interest, and let Others Take The Lead on FMS's.

These Engineering & Money Drains Greatly Slowed Development on all Main Products of Strippit.

If only Management had let Carbone, Stein, Marzullo, The "Shark", and other Bright Engineering Boys & Girls, Design New & Innovative Stand-Alone Punch Machines, Laser Machines, and Tooling,

Which Is What Built The Strippit Co. In The First Place!

Amada Leapfrogged Strippit with "Bridge-Frame", "Auto-Index" Tool Stations, and "Long Tooling".

The Door was Left-Open for Mazak & Cincinnati to take Burgeoning Laser Market.

It's Hard To Believe (But is True) that Strippit Shipped It's First Laser 7 Years Before Cincinnati 1st Laser!

Kenny Slawson (CEO Du-Jour) Always Wanted Strippit to be a "HI-Tech" Co. and Didn't Like "Low-Tech" Tooling. The Many Dumb-Kenny Jokes from Strippit Alumni are Amazing. This Allowed Wilson Tool to make Huge Inroads in to Lucrative Tooling Market and Wilson eventually Bought All of Strippit's Tooling Division. Strippit Doesn't Even Make "Strippit Tooling" Anymore! How Pathetic.

Wilson Tool is Now a Larger Company than Strippit! Another, Of Many, Real Smooth-Moves by Kenny.

Strippit had Unique Advantage of making their Own CNC Control Tailored just for their Own Machine Tools. This made them Very Easy To Use & Operator Friendly. But were first shipped way back in 1978 when they were Not quite ready (didn't have Program-Store Memory in a CNC Control, because Engineering was still working on design), but Management & Marketing Guys said "Ship Them" anyway. These Early HECC80 Controls had some problems. Engineering Rapidly Improved HECC80 Controls until they were Quite Good, but damage to Strippit's & HECC80 Control's Reputation had been done. To this day, HECC80 Controls have a Undeserved bad reputation in the industry, even though it is Certainly no worse (and Better than Most) than anyone else's Control made in Early Pre-IBM PC Computer Era of Late 1970's.

Try to get Repair Parts & Support from Fanuc or Amada on your Old Fanuc 3000 Control!

See My Web-Page on the Various Strippit HECC80 Control Types, Problems, and Fixes, Our Specialty!

Eventually, Houdaille Electronics Division was Closed as Strippit decided to Get Out of Control business (100% of it's output now went to Strippit, as Houdaille had already Killed-Off Burgmaster and Di-Acro Companies). Strippit then Dabbled with Apple Mac & DOS & Windows PC Controls for a while, which

are Very Hard to Support Nightmares. I Would Avoid All These PC Controls Machines!

Finally Strippit went with Fanuc CNC Controls on all Machines. Not a bad thing, as Fanuc makes reliable Controls, there is World Wide Support, and Fanuc's have become easier to operate & use. Old Fanuc Controls had a Zillion Buttons, Knobs, Dials, Bells & Whistles, and Looked like Tokyo At Night!

Problem is, Everyone uses Fanuc's, so your Punch becomes more like everyone else's. You have Lost Selling-Point of having a Custom CNC Control Crafted just for Your Strippit Punch Machine. Old HECC80

Strippit Controls were Famous for Good Schematics & Troubleshooting Guides, and you could Actually Fix them! Don't think so? Ask-For & Look at Any Other Manufacture's Manuals Before You Buy!

Fanuc Believes In Total Secrecy, they Won't Even Let Their Own Servicemen Have Schematic Drawings!

You Will Never Have Electrical Schematics Drawings For Any Fanuc Machine Controls!

It's said LVD had a Cash Flow Bind after Buying Strippit. So LVD-Strippit Sold Strippit's Hydra Spring Product-Line to the Noble Die Components Co. LVD-Strippit then Sold-Off Strippit's Unitized-Tooling,

See "Merchants of Debt: KKR and Mortgaging of American Business" by George Anders.

Another Odd Thing, Is How Manufactures Talk about How "Important Customer Service Is", But they Treat their Service Dept., Tech-Support, and Service Personnel as Bastard Children.

This Tends to Drive-Away your Best Service & Support People,

and All the Valuable Experience they have.

And You, The Customer, will Pay for this Turnover Trend with

Incompetent, Slow, and Expensive Service & Tech Support.

Demand Better Service! Your Business Depends on it!

One Thing I Really Don't like about Amada Company is their Claiming & Bragging to be "Best" & "First"

in Everything they make. Common Sense Says this can Not be True. Example is Amada's False Claim

to having "First Bridge Frame Turret Punch Press in the U.S." in 1974. This is Absolutely Not True!

Notice to All Strippit Alumni;

If You Worked for Strippit or Other Houdaille Company in 1980's, You May Have a Retirement Annuity

Set-Up for You that You May Not Know About! During Their Buy-Out Shenanigans,

By Law, You Became Instantly "Vested" when "Houdaille" was Magically Transformed into "Idex".

It Does Not Matter if you Later Quit, or if You worked Less than 10 Years with a Houdaille Co.

There also May be More of these "Instant Vesting's", From the Later "Idex" to "LVD" Buyout.

Call Strippit's "Human Resources" Dept. at 800-828-1527 for More Info and Metlife / Brighthouse

It's Your Money!!! To Satisfy Legal Retirement Vesting,

Strippit / Houdaille / Idex Bought Annuity-Contracts with the Travelers Insurance Co.

However, Strippit was Not the only Company in Stupid Buyout Shenanigans.

Citigroup Bought Travelers. Then Citigroup Sold Travelers. Now Metlife Bought Travelers.

Then Metlife spun-off "Brighthouse Financial" in 08/2017, You Just Can't Make This Shit-Up!

Check-Out "Idex Corporation / Strippit / Di-Acro - Houdaille, Inc. Group Annuity Contract: GR-13111"

Brighthouse Life Insurance Company at The Newest-Address ;

Brighthouse Life Insurance Company, Charlotte, NC 28277

Brighthouse Life Insurance Company of NY, New York, NY 10017, New York only!

Brighthouse Life Insurance Company P.O. Box 14710 Lexington, KY 40512

OLD Metlife Insurance Company of Connecticut, One City Place, Hartford, Connecticut 06103 - 3415 Phone 800-521-3099 Web Address http://www.metlife.com/

OLD Travelers Life & Annuity Co., P.O. Box 990023, Hartford, CT 06199-0023 Phone 800-521-3099

Yea! 2020 I'm Finaly getting My Annuity Payments for my TopSail Beach "Extra-Sweet Margarita" Fund!

Note #1, The Thor Tooling Co. has Closed its Business.

Note #2, Wilson Tool Co. Bought-Out Strippit Co. Tooling 12/2001 & Canadian Exacta Tooling Co.

Note #3, Most New CNC Turret Machines are Gravitating toward Thick-Turret Tooling, Not Thin-Turret.

Note #4, People New to The Punching Business, Are Confused by the 4

"Strippit Thin-Turret" Punch Tooling Sizes. A Discussion of these 4 Types and How to Tell Them Apart

is on My "Super 30/30 & Other Strippit Single-Station Machines" Web-Page. Go Read it !!!

There Are Other Styles of Punch Tooling besides "Thin-Turret". Some Other Tooling Types are;

"Thick-Turret", is also known as "Long-Tooling" & "Amada-Tooling"

"Salvagnini Type 1, 2, & 3 Tooling", Type 1 for Older, Type 2 & 3 are for Newer Salvagnini Machines

"Trumpf-Tooling", Special Tooling Made for Rotating Punch-Head Trumpf Machines & the Many Imitators.

"28xx-Tooling", Heavy-Duty Tooling used in Old Whitney and Old Strippit FC1500/45 Machines.

"36TC & 44TC-Tooling", Heavy-Duty Tooling used in Newer Whitney Machines.

"Wiedemann-Tooling", Heavy-DutyTooling used in Old Wiedemann & some Old DiAcro Machines.

And of Course, None of these Types of Tooling are Interchangeable!

It's a Short-List of Tooling Manufactures, if there are Others, Please Let Me Know!

You have to Identify Your Shop's Needs (Not Wants). Identify Table-Size Required, Tonnage Needed, is Auto-Index Needed & How Many A/I Stations, Flexibility & Features of Hydraulic-Ram, Or the Proven Repeatability of a Mechanical Press, How many Turret-Stations, Tooling-Type, CNC Control Compatibility & Features, Programming-Code Types, Down-Loading Capability, Programming Software Needed,

and The All Important Repair-Service & Tech-Support & Repair-Parts Availability and Cost.

Most Customers make their Big Mistake getting Hung-Up on a "Cheap-Price" or "The Deal", and buy a Machine on Price instead of Best Machine for Their Applications. I see Shops with 2, 3, or Even 4 Different Brands of Turret Punches Side by Side! I ask them about their First Machine, Story usually goes like this; "Well, We did Really Well with that First Machine for Years, But then Salesman from XYZ Co. made us a Good-Deal, So We Thought We'd Try It". Try It? This is Juvenile & Unprofessional Thinking to be Betting Your Business On! Perhaps they saved Some Money on Initial Purchase, but they Pay for it Every Day with Hidden Costs of Incomparable Software & "Part" Programs, Different Tooling, Control & Machine Operation, Table Sizes, Electronic & Mechanical Spare Parts, Operator Retraining, Etc. Do your Research, Pick a Brand, and Stay with them Until they give you Good Cause to Switch!

Small Shops make This Mistake Over & Over again with Used Machines. If its "Cheap" Enough,

they Will Buy Anything! Then they look around (After they Buy It, Never Before!) and Are Surprised when there are No Parts, No Tech Support, and No Service Available, and they Can Not Make It Run.

Pay the Money and Buy the Machine that You Really Need, and will Do Your Work! Not what is

"On-Sale" this Week. You will have to Live with it for Many Years after that "Cheap" Price is Forgotten!

I get Emails from all over the World from Shops in Countries like Thailand, Brazil, India, Dominican

Republic, Costa Rica, Columbia, Philippines, Ecuador, Turkey, South Africa, Korea, Mexico, Nigeria,

Pakistan, Etc. They Buy Old Used Cheap Machines and move them thousands of miles to where there is

No Service & No Parts Available, and can Not make them Run. They are Wasting their Time & Money.

CNC Machines are Complex, and Require Much Expertise in Operation, Set-Up, Programming, Maintenance, and Tooling, before you can make even your First Part. Its Not like moving 100 Identical Mechanical Textile Machines, that local guys can get some running, and then use those as Examples to Tinker with, Scavenge Parts, & Figure-Out How to get the rest of them running.

These Shops would be Much Better-Off Buying a New Machine from a Local Dealer that

Sells & Services & Stocks Repair Parts & Supports Their Machines in That Country!

There are Many Good Dealers, But Beware of Bad Ones and their "Bait & Switch". Some "Pawn-Off" Old Machines in their Warehouses to Overseas Countries. See prospective Machine Run and get its Serial Number. I hear Stories of "Oh, That Machine was Sold, but I have this Other Great Machine you can have

at Same Price". Especially if it's in a Warehouse & Not-Running, Negotiate Guaranteed Installation &

Start-Up, and a 60 Day Written-Warranty with Machine Purchase. It Is Well Worth the Extra Cost!!!

Now, For a Case Study on How-To Run a Company, Do Research on Hass Automation Co. They Do Everything Opposite to Strippit-Way of Running a Business. CEO is a Machinist (Not a Harvard MBA)

who Believes-In & Is Involved-In Innovation of their products, Engineering, Customer Service, & Product Improvement. They Don't "Out-Source" they do their own Machining & Manufacturing, and Designs and Builds Their Own CNC Control, Hardware & Software, for Their Machines Just Like Strippit Used to. Result? From Hass's Start in 1983 (When Strippit was at its Peak!) Hass has grown from 0 to $700,000,000. in Annual Sales, Employs over 1000 Here-In-The-U.S., and is Still Growing!

Proving that you Can Manufacture Here in the U.S., and You Don't Have To Out-Source!

You just have to be Smart and use Good Machine-Tool People, and Not Stupid "MBA Money-Grubbers".

Thank's Strippit!

Go Get'em, Chris!

There is a Pattern Here, Can Anyone See what Strippit was Doing to Their Business & Reputation?

Another Misstep (Which Strippit has Done So Many Times with Haeger Pem-Serters Machines, AEM Finish-Sanding Machines, Italian Power-Notch Machines, Accu-Center Coordinate Measuring System, Etc.) was Importing Nisshinbo Punch Machines (SPM500's & SPM750's) from Japan, Re-Painting them, and Calling them "Strippit" Machines! After CAP Machines, this was their Next-Try at Cheap "Entry Level" Strippits.

They always do this a few years, then Drop Machine Lines when they Fail to make Bags of Money off Sales, and Actually have to Stock Repair Parts & Service these Machines. Strippit Dropped Nisshinbo, which made it Easy for Nisshinbo to Open Their Own U.S. Sales & Service Outlet with More Ex-Strippit Alumni

(Hi Dave, Bob, & Chris!) as Owners. Another Clever Strippit Management Move, Set-Up Competitors!

Now Strippit is Working with the Chinese. I'm Sure That will be a Really Big Help! 1800's were the British Century, 1900's was Definitely American Century, but I'm Afraid This Century will Shortly Belong to China & India. Have your Kids Learn Mandarin so they can get a Good Paying Job with a Multinational Company some day Soon. You Have to Admire the Chinese though. They Wisely Focus on Taking Care of China, and Do Not Waste Their "Blood & Treasure" Trying To Be "The Cops of The World".

I Wish Our Boys & Girls in Washington were Half As Smart & Dedicated as Chinese Leaders

Who have Played Us Like Fishes. And Just Take Care of Our Own, Here in The United States.

Required Reading in Washington should Include "China the Gathering Threat" by Dr. Constantine Menges.

Strippit vs Amada

If you have Suffered with Me this Far, you Deserve My Answer to "Strippit vs Amada" Question. I Again

Say You Must Do Your Own Research, as each User has Unique Needs, Requirements, & Situations.

What is "Best" is an Arbitrary Term. I think "Best" is the Most Reliable Machine. Most People want Ability to Come-In in the Morning, Turn Machine On, Run Parts All Day with No Problems, and Shut It Down at End of the Work Day. And do this Every Day, Year in & Year Out. Some Managers (Long ago, in Another Era) when I was at Strippit, told be that "Yea, Our Machine's Break Down more than Amada, But we're So Much Faster, Our Machine's are Still More Productive". This View Conveniently Overlooks many Factors, like Repair Costs and Scheduling Nightmares, and I have Never Agree with it.

Machine Companies Push Speed, because they Sell to Companies by Doing "Justification" Studies.

If They can Show You, on Paper, that their New Wizzy-Bang 1000ZZ Machine Can Punch, Say, 30 Holes More Per Minute, Times the Hours in Your Shop Work Day, Times your Shop Rate, Etc, Etc., then This Machine will Pay for Itself in only 17 Months or so, and You Would Surely be a Fool Not to Buy it!

These are My Opinions based on My Experiences Working on Strippit's, Amada's, Di-Acro's, Trumpf's, Raskins, Nisshinbo's, Wiedemann's, and other Machine Tools for 45+ Years.

Companies & Technologies & Machines are Constantly Changing, and Nobody is a Expert on Everything.

I Freely Admit My Opinions could be in Error or even Wrong, and are Primarily for North American Market.

I will Change my Opinions from Time to Time based on New Information, and Will Update this Web-Page & Web-Site as Time Permits. I will Not Rate Brands 1, 2, 3, Etc., But will Separate into 2 Groups, The Best, and All The Rest. Note there are Many Excellent Machines in "All The Rest" Group, They are Not Presented in Any Order and All should be Considered! Use "Hot-Links" to do Your Research!

"The Best", 3 for the North American Market

Trumpf

Used Correctly in Right Applications, Trumpf is probably Most Versatile and Productive CNC Punch Machine there is. Trumpf is a Company that seems to be Engineering Driven, instead of Marketing & Bean-Counter Driven like most Companies. They Do Everything Their Way. Other Companies use Turrets, Trumpf uses a Tool Changer. Others have 2 to 4 Auto-Index Stations, Trumpf's Punch-Head Rotates so Every Tool can be Auto-Indexed 360 Degrees, their big advantage. Trumpf's use only "Trumpf-Style" Tooling, though Mate & Others make this Tooling Type now. Other's Buy Ballscrews for Axis Motion, Trumpf uses Precision Rack & Pinion Gears Made in their own Swiss Factory. Trumpf has Probably Best Trained Serviceman in this Industry. I Prefer their 27 Ton Machines over lighter 22 Ton Machines. There are many Imitators of Trumpf Tool & Rotating Head Concept.

Trumph-Way in Machines & Tooling & Service tends to be Expensive. Trump buys little "Off The Shelf" Parts as they like to make everything themselves, so there is No 2nd Sources of Repair Parts. Machines are Complex, sometimes Too-Close to "Bleeding Edge" of Technology, and Difficult to Repair without Factory Parts & Help. They are Not Built to Take Day-In & Day-Out Use & Abuse with Zero-Maintenance that is Typically Given Machines here in U.S., Canada, and Mexico. German Trumpf uses German Bosch and Siemens CNC Controls. There is nothing wrong with this, but they are not Widely Used Controls here in U.S., which limits 3rd Party Venders of Parts & Service. Like Fanuc, Good Luck trying to get Control Schematics and they would be in German. I consider Trumpf's to be Precision Sheetmetal Machines and Not for Heavy Gage Materials like 7-Gage or 1/4" Steel. One Reason is they use "C" Type Frame, which acts like a Big Vibrating Tuning-Fork under Large Loads, verse more Rigid "Bridge" or "O" Frame that is becoming Standard of Industry. Trumpf Disputes this, but you would be better off with a 40 to 50 Ton Amada or Wiedemann or Whitney if you want to Punch Heavy Materials. A 30-Ton Bridge-Frame Trumpf would be a Interesting development.

LVD Strippit

Strippit in Akron NY, makes good CNC Punch Machines. Engineering is good and build quality is good. Combined size of LVD & Strippit gives them access to more resources to advance products. Strippit has a Wide Catalog of Machines, from small Entry Level Machines, to Large-Table Models with Load / Unload Systems. As they are Located-In and Built-For North American Market, Strippit's Machine Designs tend to be more Robust than European Machines. This is because of Unfortunate Fact that Most Shops in U.S., Canada, and Mexico, do little Training of their Personnel, use "Button-Pushers" to Run Machines, and do little Maintenance. European Shops I toured, had Professional & Well Trained Personnel running their Machines and organized Tool-Rooms that Delivered Sharp Tool Set-Ups Just-In-Time for next Job. I used to see this in America, but not anymore. The Point is, Strippits Hold-Up Relatively Well in this Tough Environment. Strippit Turrets have Large Auto-Index Stations and Hardened Replaceable Tool Bushings.

I Prefer Thick-Turrets & 30-Ton Machines over Lighter 22-Ton & Thin-Turrets Machines.

Belgian Company LVD bought Strippit in 1998, Latest in a Long String of Buys & Sells Strippit Co. has Endured in 1970's, 1980's, and 1990's. These caused Strippit to Lose Focus on their Customer's and Machine. And so, Competitors passed them by. Both Amada & Trumpf are now 2 Billion Dollar a Year Companies, can afford more Research & Development on New Products, and Spend More on Service & Customer Support. Strippit's Machines seem to have 2 Problems. First is some Inconsistency in Machine Building. One Customer has a Machine with a Turret Problem, another has Perfect Turrets, but something Completely Different Wrong. There are some Control Integration Problems on complex Machines like Combo Punch/Laser Machines. Other is their Well Known Service & Support Problem. I thought that I had Shamed Strippit into Hiring more Service People. But, a Customer called and Complained "I'm only 30 Miles from Strippit, and I Can't get my Machine Fixed!". Another called Fuming-Mad, as Strippit Tech-Support Told them they were "Not Smart Enough" to work on Their Machine! This may have been true, but you can't tell them that! And this is in Good-Old 48 States of the U.S.A., where Strippit Service is at it's Best! There is Damn Little Strippit Service Outside U.S.! Canada is Just 22 Miles from Strippit's Akron, NY Plant, Yet there is No Strippit Factory Service in Canada! And There is No Strippit Service in Mexico,

a large market these days. Yet Competitors manage to Service these Countries.

I, and Many Other Independent Servicemen, used to have a Good Relationship with Strippit. I Pushed the Strippit Brand and helped Strippit Sell New & Used Machines, and for No Commission. I sold Strippit Hard to find Parts and they gave me Part discounts. Then LVD Strippit Decided to make Their Friends into Enemies. That's Always a Real Good Business Strategy. We though it was because we were perceived to be Service Competitors. But Strippit Insiders told me their New Policies came from Strippit's Comptroller (Head Bean-Counter). His Wet-Dream was Thinking that some of Strippit's Dead-Beat Customers were getting their Parts & Service from us, to Avoid Paying-Up on Past Due Bills to Strippit. Strippit has always been Very Aggressive on Bill Collecting. So He would Cut Us Out, and Strippit could Squeeze These Customers into Paying-Up! In so many ways, LVD-Strippit shows that they Just Do Not "Get It".

Instead of being "Partners", Strippit has an Adversarial Relationship with Customer's, Employee's, and All Independent's, and so keeps Relegating Themselves to 2nd-Class Status.

Up-Date; With LVD Buying Strippit I had Hoped Strippit would Turned-The-Corner. They have had Poor Past (and Present?) Management that wasted the Company. They got rid of some Excess Models and Fixed their Hydraulic Problems. I liked some of their Innovative Thinking (Which was always Strippit's Forte) like Robot Loader-Stacker. But, U.S. Service & Support & Repair-Parts Availability is Still So Bad, I can Not Recommend them anymore. And it's even Worst in Canada, Mexico, and Rest of the World.

UP-Date 2021; After being The Leader in Punch & Laser for a Century, LVD has Killed The Strippit Co.

The Remnants are now known as LVD Services Co. Good Luck With That.

Amada

They Build Big, Heavy, Tough Machines that were the Most Reliable in CNC Punch Machine Business. Amada Works Closely with their Fellow Japanese Partner, CNC Control Maker Fanuc, who seems to Give Better Technical & Integration Service to Amada, than they do to their Non-Japanese Customers. This gives Amada an Advantage that is Hard to overcome, as Fanuc Controls just seem to Work Better on Amada's, than they do on Everyone Else's Machines. Amada has a Large & Relatively Good (but Certainly Not Great) Service Dept., with Many Support Centers in U.S. & Worldwide. Good Repair Parts Availability, offers Repair Service Programs, and New CNC Control Retrofits if you desire them.

Amada is Certainly Not Perfect. Their Machines Tend to be Slower, usually are Not Innovators of Newest Features, and Still have Old Turret Wear-Out Problems that they Refuse to Address. I would be Wary of "Thin" Turret Amada's, and only go with "Thick" Turrets & Thick Tooling. Make Your Operator's keep Turret Bores & Tooling Very Clean, and Turret Bores & Tooling Well Lubed with Premium Synthetic Grease, or you will Need New $60,000 Turrets Installed every few years. Amada's 1st Generation Machines used Mechanical Rams that had Crankshaft & Bearing Wearout Problems. 2nd Generation used Hydraulics that were very Reliable, but used Much Electricity. Now they Only make "EM" Servo-Electric Ram Machines.

I thought Amada would Ease Into "EM" Machines and Offer them as a New Alternative to their Older Bulletproof Hydraulic Machines. But, Amada has Dropped All Hydraulic Punch Machines and Only offers EM's. This is Unproven Technology. They use 2 Big Electronic Servo-Drives that Drive 2 Big Servo-Motors, that Drive Ring & Pinion Gears to Turn a Mechanical Crankshaft & Ram. So they have returned to 1st. Generation Greased Crankshaft & Bearing Problems. And Worse, according to Amada, 2 Servo-Drives & 2 Servo-Motors would Cost over $80.000.00 to Replace if they ever go Bad in the Future. If your Knuckle-Head Operator Crosses a Tool or Punches a Workclamp, a Mechanical "Fuse" will Break, Requiring a Service Call to Repair. Better get a 3 Year Warranty on a New Machine and Buy Amada's Extended Warranty afterward. There are Reports of Design & Service Problems with EM's, Owner's Please Fill me in on your Experiences. I have 1 Customer with an Older Amada that will be "Down" for 2 Months while waiting for an Un-Stocked Part from Japan. Amada No Longer Offers "Entry" Machines for Little Shops, preferring to Sell Only 2 Big Expensive Punch Machines with Pricing starting at $380,000 & $420,000!

"And The Rest" Good Machines to Be Considered, Listed In No Particular Ranking Order;

Finn-Power

Finn-Power builds Machines that seem to be High Quality & Innovative, using Turret Punch Machines with Hydraulic Rams and "O"-Frames (Their Name for a Bridge-Frame) and also their own Servo-Mechanical Ram, the "E" Series. It would seem More Companies are Backing-Away from Problems of High-Speed Hydraulics. While they make Stand-Alone Punch Machines, Finn-Powers Claim to Fame is their Automation. Their Machines are built as Building-Blocks that can be Assembled in Different Configurations, depending on Customer Needs, into Flexible Manufacturing Systems (FMS) that Typically have Sheet-Storage, Sheet-Loader, Turret Punch, CNC Right-Angle Shear, and a Unloader / Parts Sorter.

Some Years back, Finn-Power had Financial Problems, and a Private Equity Fund now Owns them. This is Not necessarily bad, but Repeated Buying & Selling of a Company is what Damaged Strippit. New Owner's seem to be Investing Heavily in Finn-Power to Grow their Business. They have some Really Large Table-Size Machines (Up to 169 Inches) but Strangely, most of their Turrets are Small (20 Stations) in Capacity. Finn-Power's "E" Machine's approach to a Servo-Ram sounds kind of Hokey to me, so user's, Please give me a Update on it's Longevity after you have had it a while.

Nisshinbo

Nisshinbo is a Large Japanese Conglomerate that makes Textiles, Toilet Paper, Brake Shoes, Chemicals, Etc. In early 1980's, they made Small CNC Turret Punch Machines for their own use in making Textile Machine Parts. In Mid 1980's, Strippit Imported SPM500 & SPM750 Nisshinbo Punch Machines, Repainting them in Strippit Colors , and Sold them as "Strippits". For Small and Light Gage Parts, these Machines Worked OK. But many Job-Shops bought them because they were Cheap, tried to Punch Anything on them in usual American Way, and had Problems because they really had bought Too-Small of a Machine. Many of these Machines were Returned to Strippit, Rebuilt, and Sold Again.

After a few Years, Strippit and Nisshinbo parted company. Nisshinbo Expanded their Machine Line, and came out with Larger MAP1000 Machines. These were OK Machines, and as they were inexpensive, were a Good Value. In 1990's, Nisshinbo continued improving and came out with Big Machines like HIQ-1250 Series. These were good Machines that were Robust, Well Built, and Reliable. But there Is A Problem with Nisshinbo's. They Quit Making Them! Punch Machines were a Small Part of their Business and they had a small share of World Market, so Nisshinbo Quit Manufacturing Punch Machines. Parts, Service, and Factory Technical Support Availability to keep Machines Running is Already a Problem!

Yawei

A Chinese Company that has Roots going back decades, Yawei started to make Advanced CNC Machines in 1990's using Swiss, Italian, and Japanese Technologies. As Nisshinbo Phased-Out their Punch Machine Manufacturing, they Partnered-Up with Yawei and Transferred Nisshinbo Manufacturing Technology Know-How and Critical-Parts Kits, to enable Yawei to build Copies of their HIQ Series Machines. This Series has been Improved with Stronger "O" Machine Frame and renamed the HPI Series. HPI Machines seem to have all the Required Good-Stuff, a Strong "O" Frame, Thick-Style Turrets with Hardened-Bushings, Brush Tables, German Hydraulics & Controls, and All in a Proven Nisshinbo Design.

I have little First-Hand Knowledge of Yawei Machines and this is Not an Indictment of Yawei Quality. But I have heard of Yawei Quality Problems. And I Do Have Knowledge of other Chinese Machine Tools that were of Poor Quality. Chinese are Not Known for Good Quality Control, and will Ship Crap if Not Watched Carefully and Constantly. A Good Design is Only The-Start, Machine Components Must be Manufactured Correctly, with Proper Tolerances, Made with Correct & Proper Materials, and Assembled Correctly by Skilled Personal, or you will Not get a Reliable, Productive, Long-Lasting Machine Tool! Yawei Must Provide Good Technical Operation & Repair Manuals, Repair Part Drawings, and Electrical Drawings, in English, if they Expect to be a Respected Player. Plus the All Important Repair Parts, Tech-Support, and Service Availability. How well they Accomplish this will determine the Reputation they Build.

NC MEC USA

When Strippit & Nisshinbo Parted-Ways, several Strippit-Guys left and Formed NC MEC USA Co. NC MEC is Independent & Excusive North American Sales Distributor for Nisshinbo and Yawei Machine Tools. They Stock some New & Used Machines, Repair Parts, Provide Technical Support, and Field Repair Service. Located in Buford, GA., NC MEC does a reasonably good Job, but is a Small Organization which limits Parts & Service availability. They have some Service Personal and also use sub-contracted Independent Servicemen. Phone Tech-Support is available, but may charge for it. If you have a SPM500 or SPM750 "Strippit" Machine, Strippit has Little or No Support & Parts, so go to NC MEC USA. Nisshinbo and Yawei Do Not Directly Support their Machines in North America, you have to go through NC MEC. Nisshinbo Machines have been Discontinued and Yawei has been Phased-In. If Yawei Decides to build Quality Machines, and if Yawei & NC MEC Decide to Support them Well, they could be a Force in Marketplace, as their No-Haggle Machines Prices are much Less than Competitors. I was Disappointed NC MEC did Not bring a Yawei to Atlanta Machine Show (Neither did Amada or Muratec) or to Chicago Show. They believe it's a Waste of Money, but I think they made a Mistake, take a Machine to the Shows!

Tailift

Taiwan Co. Tailift makes a variety of CNC Turret Punch Machines with Mechanical, Hydraulic, and Servo-Hydraulic Punch Rams. Different Technologies have Advantages & Disadvantages, analyze carefully to get Punch Technology that Best Fit Your Needs. Machines appear to be Copies of Amada Punch Machines. Tailift has small U.S. presence, and unknown Parts & Tech-Support & Service.

Alternative Machinery Sales Inc.

Upside for Tailift is their U.S. Distributor is Alternative Machinery Sales which is Part of Alternative Parts Inc. (API). API is a Parts and Service Company that has done a Good Job supplying Parts & Service for Amada Machines for many years. I expect they will do a good job of supporting Tailift Machines.

Murata / Muratec / Wiedemann

Wiedemann Company was Started in 1916 by Theodore Wiedemann, and Invented Modern Turret Punch Press Machine in 1964. Later became part of Warner-Swasey Company and were Located in King Of Prussia, Pennsylvania. In 1980's, they, like Most of American Machine Tool Industry, fell on Hard Times. Wiedemann was bought by Japanese Murata Machinery Ltd., and were moved to Charlotte, NC.

The New Murata Machinery USA Inc. now makes Punch & Other Machines under Brand-Name Muratec.

Old Wiedemann's Traditionally were Large, Solid, and Heavily Build Machines that used Mechanical Press Drives Systems. They used "Wiedemann Tooling" in Turrets that were Bored, but Not Equipped with Replaceable Bushings. Machines performed well, but were Slower in Speed than Competition. Wiedemann seemed to Rest on Their Past Laurels, and so became a Follower of New Features other Companies were coming out with. In 1990's, Wiedemann Pioneered Servo Motor Driven Ram. This Technology uses a CNC-Controlled Servo-Drive Mechanical Mechanism to Precisely Control Punch-Ram and it's Speed-Profile & Stroke-Length. Technology does Not have High Electrical-Usage or Positioning-Problems Inherent in High Speed Hydraulic Punch Systems. Murata makes a Wide Variety of Punch Machines, Perhaps Too Many to adequate support, Ranging from Motorum Servo-Drive Ram Machines, to Hydraulic-Ram Vectrum's, to Big 45 & 50 Ton Mechanical Press-Drive Centrum & Magnum Machines.

Pullmax

Pullmax uses a Turret just as a Tool Magazine, as Tools are Selected, they are Loaded into Punch-Head, which can Rotate 360 degrees with All Tooling. Newest Machines can Form-Upwards to 3 Inches, so some Small Parts may not need a secondary Forming Operation in a Press Brake. Punch Head is Hydraulic and can be 24 Ton or Optional 33 Tons of Punching Force. Pullmax currently uses Fanuc Controls.

Turret is a Small at 20 Tool capacity, though All Tools Rotating is a big help. Pullmax has a small Presence in North America causing usual Trouble getting Parts, Service, and Technical Information. Most Repair Parts are Not-Stocked here and have to be Flown-In from Factory in Sweden.

Rainer

Italian's have always been Innovative and Rainer in Bologna Italy is no exception. Sister Co. of Rainer-UK is Punch Press Services Co. located in Sandbach, UK. 9 Models with Hydraulic Ram and "C" Type Frame. Manufacturing & Packaging advantages to "C" Frame, but it is not as Ridge as "O" Frame. I remember Strippit Mechanical Engineers were Shocked at how Much More Ridge "O" Frame was than Their Computer Models Predicted when they started making this type Frame again. Some Rainer Models use 2 Servo Motors & 2 Ballscrews to Move Y-Axis. A Good Idea (Nisshinbo did this years ago on HI-IQ Machines) as it provides Better Positioning of Large Loads on Big Work-Tables and High Axis-Speeds. An Innovation is Rainer's "Orbital" Turret System with Lower-Turret Off-Set to side of Upper-Turret allowing Easy access to Examine & Simply Lift-Out Dies! Turrets are In-Sync & Line-Up Only at Punch-Ram Position, which is Only place it matters. Small Presence in U.S. causes Problems of Limited Parts & Tech Support.

Durma

A large Manufacturer of Sheet Metal Equipment started over 50 years ago in Bursa, Turkey. Machines seem to be Well-Built, but I have little experience with Durma, as they have a small Presence here on our East Coast. Durma Machines are being sold Mainly by 1 Distributor on U.S. West Coast. Punch Machines are fairly Conventional, and use a Bridge Frame, Hydraulic Punch Head in 22 & 33 Ton Versions, 26 & 28 Stations Tool Turrets using "Long-Tooling", Siemens CNC Controls, with Brush & Ball Work Tables.

While Durma is a Large Company in Europe, they have usual Problems of a Small Presence here in U.S., which Limits Repair Parts, Tech Support, and Repair Service availability here.

Danobat

Spanish Company Danobat is part of a large Industrial Group that makes a variety of Machine Tools. They make 2 "Medium" Punch Machine Models with Large Work Tables and a Full 30 Tons of Punching Force, unusual in small to medium Machines. Danobat makes 4 "Large" Models with "O" Frames which have Large Tables that can process a Full 4' x 10' Standard U.S. Sheet of Metal without a Progressive-Move, a big advantage in Processing Speed & Accuracy. Seem to be Good Conventional Machines with Tool-Turrets, Auto-Index Stations, Hydraulic Rams, Brush Tables, Etc. I am told that there is only a few Danobat Punch Machines in U.S., so Repair Parts, Tech-Support, and Repair Service is limited.

Whitney

Whitney is located in Rockford, Illinois. Lightest Machine is Rated to Punch 40 Ton Holes in 1/2" Steel Plate.

Their Big Machine is Rated to Punch 100 Ton Holes in up to 1 Inch Plate! Machines use Tool Changer that loads Tool-Set from X-Axis (or External Tool Caddy) into Punch Head, which Rotates 360 degrees, so all Tools "Auto-Index". Punch Tooling is Heavy-Duty 28xx, 36TC, or 44TC Types and most Machines have Plasma Cutting for Contour-Cutting. Expensive and Slow compared to Lighter Sheetmetal-Type Machines, but this is Heavy-Plate Punching Machine. Buy Correct Machine for Punching Jobs that You Need to do!

Pivatic

I thought years ago it would be smart to add a Coil-Line to Feed a CNC Punch Machine for High-Volume Part Production. Pivatic, in Hyvinkaa Finland, has accomplished this. Full Coils are Economic way to Buy Sheet Metal. Pivatic makes a Line of Un-Coilers, Levelers, Sheet Stackers, Loaders, Punches, Shears, Benders, and other Machine Modules to be used alone or assembled into a Flexible Manufacturing System (FMS). Punch Machine uses 2 Tool Cassettes that hold up to 104 Thick-Turret Tools with each Tool having it's own Hydraulic Ram so any Tool can Punch at any time. Cassettes move Back & Forth in "Y-Axis" while Sheet Travels in "X-Axis". Both Coil and Sheet Versions of Punch Machines are made. If you are a High-Volume Parts user, you would want whole Coil, Leveler, Punch, Shear, Bender, Stacker System so Metal Coils go in 1 End and Parts come out other End. I see Salesmen and Distributors here in U.S., but I don't see a Service Organization to Supply Parts and Field Service to keep Complex Machinery running.

Salvagnini

Salvagnini, located in Italy & Austria, is a Leader in Integration of High-Volume Sheet Metal Part Production. Originated "Multi-Press Punching Head" that hold 40 to 96 Tools, each with it's own Hydraulic Ram so each Tool can Punch at any time. "Heads" use Unique Salvagnini Type 1, 2, or 3 Tooling. Some Models have Sheet-Rotator so Part Sheets can be Punched and Trimmed on all sides. Salvagnini's are best used in large High-Volume FMS Systems using Integrated Sheet-Loaders, Punch, Shear, Bender, and Parts-Stacker. Big, Complex, Expensive Systems that I have only seen running in High-Volume Carrier, Trane, & G. E. Plants, and may Not be suitable for Smaller Operations. Salvagnini has a U.S. Support & Service Center in Hamilton, Ohio, but you need a Good Maintenance Dept. to take care of this Machinery.

Next, LVD-Strippit Sold-Off Entire Fabrication Tooling Product Line "Strippit-Tooling", Which Strippit Invented, to Wilson Tool Co. December 2001. Another Incredibly Stupid Move!!! An Interesting (And Telling) Comment on American Business Styles, how Privately-Held Wilson Tool Co. Prospered & Grew Making Strippit Tooling, and is Now Far Bigger than the Strippit Co., while Strippit, with

It's Buy-Out Owner's Du Jour, Floundered & Shrunk in Size for Years! Go Figure.....

SAF (Semi-Automatic Fabricator) Punch Machines. More on Strippit Single-Station Machines, Click-Here!

In Early 1990's Strippit Quit Making Manual Single-Station SAF Punch Machines like the 10A, 15A, Sonic 18/30, Custom 18/30, Super 30/30, Super 30/40, Super 36/75, Super 30/40HD, Etc., that Strippit made Thousands of for the Better Part of a Century! Strippit Company was Founded on Making Tooling with Build-In Punch Stripping-Guides (Hence, The Strippit Name) that Strippit Invented. And the Single-Station Punch Machines that this Tooling Went Into. And Now Strippit Does Not Make Tooling or SAF Machines!

How Can You be A Manufacturer, If You Keep Selling Off Your Product Lines?

It's Obvious that they have Decided to Concentrate on their Big-Ticket CNC Machines for Strippit's

"Core-Business". But They Do Not Understand that All these Other Product Lines that they Sold or

Gave-Away, Were Still Money-Makers, and Represented a Powerful Synergy in Punch & Bending & Tooling Business that Had Helped to Make Strippit the Market Leader, and First Name People Used to Think-Of when they Needed these Products. And LVD-Strippit has Let it All Slip-Away!

Years ago, Before Idex Sold Strippit to LVD, The Cincinnati Press & Shear Co. Almost Bought Strippit.

Its Really Too Bad that Cincinnati Passed on this Deal, as I Think it would have been a Much Better Fit than LVD, and Strippit and it's Employees would have Prospered under Cincinnati's Disciplined Private Owners.

Strippit is Currently Owned by LVD Co. in Belgium, and is now "LVD-Strippit". I spent a week with LVD in Belgium a years ago and I was Impressed with LVD at that time. They were like Old Strippit in late 1970's, with Lots of Mechanical, Electronic, and Software Engineers because they Believed in making Best Machines they could, and doing it all "In-House". Interestingly enough, LVD is also a Privately held Co., Letters LVD are for Last Names of the 3 Families that own it. However, LVD's Integration of these 2 Companies has Been Very-Poor with little U.S. investment & they keep changing their Long Term Plans.

And So, LVD-Strippit's Sales & Service just keeps Declining, while Amada & Trumpf Prosper.

I also Spent a week with Trumpf Co. in Germany & Switzerland. Lots of Progressive Technology.

They Proudly Showed us their New $150,000 "Load-Master" Sheet-Loader System. I Told them

"Well, That's Nice. But Down South, We-All Use The Bubba-Master, And He Only Costs $8 Bucks"

We were Rolling In The Isles Laughing but The Germans Didn't Get-It.

When There, Try to "Do-Lunch" with Mr. Leibinger (Since Retired) in The Executive Dinning Room.

McDonald's Will Never Seem The-Same Again! But, That's Another Story, for Another Day.

I Certainty Do Not Know "Everything" about Strippits or Any Other Subject!

My Opinions are Based on the Above Experience, and are Simply Offered as 1 of Many Opinions that

You Should Gather & Use, and Combine with Your Own Unique Needs & Situation,

to Form Your Own Opinion, Which is the Only One That Counts!!!

Recommendations & Opinions;

Opinions are for North American Market and Do Not Necessarily hold for other Countries on our Tiny Planet.

I Favor Machines Built with Mechanical Press-Drives, but All Manufactures have gone to Hydraulic-Rams.

If you are Buying a New Machine and Need the Features of a Hydraulic Adjustable-Stroke Ram, Make the Manufacturer Prove That It Really Works, at Advertised Speeds, with Your Tooling & Sheet-Materials.

I Greatly Prefer 30-Ton Punching Force Machines Over Lighter & Cheaper 22 Ton Machines Manufactures often Push. Negotiate a 2 or even 3 Year Parts & Service Warranty, Don't Be Bashful! It's Your Money!!!

I would Chose "Long-Tooling" & "Thick-Turrets" as it is More Accurate and Suitable for Hi-Speed CNC Punching over "Thin-Turret Strippit-Style" Tooling that was Invented 3/4 of a Century ago by Old Wales Strippit Co. for Manually-Operated Single-Station Machines. "Trumpf" Style Tooling and their Rotating Punch-Head Concept as now used by Many Machine Builders is another Good Choice.

Avoid P.C. Controls & Most CNC Control Retrofits, as they Tend to be "Buggy", Poorly Documented, have Parts Availability Problems, and are Hard to Service & Support. Latest Fanuc Controls are a "P.C." with "Windows" Running-Inside and have had some "Problems". Their Hard-Drives are Expensive to replace.

The Strippit Co.

Historically, a Company that has Good Build-Quality of Machines, Good Engineering, Average to Mediocre Field Service, that has Been Hobbled by Poor Marketing & Salesmanship, and During Houdaille / Idex / Strippit Inc. / KKR Years, a Very Self-Enriching & Clueless-Management. Hopefully, LVD will Do Better.

Don't Misunderstand, Strippit Has Many Excellent Servicemen & Support People, and Salesmen. They Also have some (Just like All Manufactures) that are Unskilled, Poorly Trained, Burned-Out, & Worried about The-Next Layoff. Many are Over-Worked & Spread-Too-Thin, as Strippit is Understaffed.

This can Negate Strippit's Good Points and Brings-Down the Whole Organization to Mediocrity.

LVD Strippit Management Doesn't seem to Understand North-American Market. I get Calls from Small Shops and Large Corporations with Press-Brakes & Lasers & Punches, that Complain about "Arrogance of the Belgians" (Their Exact-Words, Not Mine). The Strippit Company is Located in Akron, New York (near Buffalo), Yet Strippit Chairman Jean-Pierre Lefebvre (The Family "L" in LVD) is My Neighbor Here in Union County, North Carolina. It's a Long 700 Mile (1100 Kilometer) Commute to Strippit Factory in Akron, N.Y, but I Guess a Short-One to his Beach House on Bald-Head Island on our North Carolina Coast.

I am also Amazed How I Travel all around the Country, and Talk to Shop-Owner after Shop-Owner, who have Never Even Seen A Strippit Salesman! Strippit's "Distributors" tend to be Order-Takers. I wouldn't use Distributors at All! Strippit should Stick to their Own Professional Factory-Trained Salesmen,

and have them "Beat The Bushes" a Hell of a Lot More, like Amada Salesmen Do.

Phone Technical Support is Poor Because of Lack of Manpower from Many Layoffs of Support & Service Personnel, and Too-Wide Present & Past Product-Lines. When I was "Tech-Support" at Strippit, I built a Library of Manuals on Every Product-Line in my "Cubical". After I Left, CEO Kenny Slawson (Known as "The Tall & Dumb One") said it was "Too-Messy", so this All-Important Support Documentation was Thrown-Out in the Dumpster! Looks over Substance. Personnel & Resources Should be Added to Important Tech-Support Group and Publicly-State what Past-Products Strippit-Is & Is-Not Going to Support.

Strippit Field Repair Service is Very Very Poor in our Close Neighbors in Canada and Mexico,

and is Even Worse or Completely Nonexistent Overseas. Check on Service & Parts Before You Buy!!!

All the Above are Very Correctable Problems, If LVD Strippit Ever Commits to Fixing Them.

New Strippits

Global 20-1215, Global 20-1515, Global 20-1225, Global 20-1525, Global 30-1215, Global 30-1515, Global 30-1225, Global 30-1525, Siena 1212, Siena 1225, Parma 1212, Parma 1225, Delta 1000, Delta 1250, Delta 1500, ST 1212, ST 1225, 1000H/30, 1250H/30, 1500H/30, 1000XP/20, 1250XP/20, 1000MXP/30, 1250MXP/30, Alpha 1012, Alpha 1212, and the Super 750. Plus the "Omega" Systems.

Good Grief, Strippit Has Way Too-Many Punch Machine Models! They Currently (Summer 2007) List 28 CNC Punch Machines! This puts a Huge Burden on Engineering, Manufacturing, Purchasing, Parts

Stock-Room, Documentation, Tech-Phone Support, and the Field-Servicemen.

How can Anyone "Know" & "Support" All These Current (And the Past) Machine Models?

To put it in Context, Amada & Trumpf are Much Larger Companies than LVD Strippit, yet Amada Lists 5 Punches, and Trumpf Lists only 4 Punch Machines. Strippit Needs to Get Rid of these Excess and Redundant Models, and Concentrate their Efforts on Great-Support of Remaining "Core" Models.

New Machines seem to be Well Engineered & Built and are Fast & Accurate. All have Reliable Fanuc Control & Servo-Drives which can be Serviced World-Wide by Fanuc & Independent Service Co's. Integration of some Machines & Fanuc Controls is Not the Best. It seems Not Enough Engineering Time was Spent at Strippit to "Get Bugs Out". This is Probably Caused by "Too-Many Models" & "Too-Many Laid-Off Engineers" Problem. Problems like getting "Error Codes" instead of Real-Messages on their CNC Controls, Poor Documentation & Electrical Drawings, and Mechanical & Electrical "Bugs" that are Poorly or Never Fixed. Different Machine were done by Different Engineers who Didn't Talk to each Other, and so used Different Machine Parts, Incompatible Controls & Software, Different Sensors, Etc. Ccaused by Poor

"Engineering Management". This makes it Difficult for Even the Factory to Support!

Machines are now Hydraulic, some of the Past Hydraulic-Versions had Various Problems, But Newer Versions seem Much Improved. I Prefer 30-Ton Machines with Thick-Turrets & Thick-Tooling.

The Mechanical Press-Drive Versions have been Phased-Out of Production.

Used Strippits

Mid 1990's to 2002

Global 20's and Global 30's. Most are Bridge-Frame Machines now, very solid & rigid. Strippit has now used 2 or 3 Generations of Hydraulic-Ram Systems, some have had Problems, I greatly Prefer the Mechanical Press-Drive Versions. Stay with the Fanuc Control Versions. Some Machines had Apple-Mac / DOS / Windows P.C. Computer Controls with Various Software & Servo Drives which are becoming Hard to Support. Avoid the P.C. Controls! All Strippit Upper-Turret Tool-Stations have Hardened-Bushings, a Big Advantage, especially in used Machines, as a damaged Turret Station can be Easily made "Like-New" again. Another Strippit Advantage is that all their Auto-Index Stations are Big 3 1/2 Inch Stations, some competitors have only small station A/I's, which are Much-Less Versatile.

1250H/20 This is 1250/20 Repackaged with a Hydraulic Press-Drive, instead of Mechanical. This was next Stab at Hydraulics, and there have been Reports of Various Problems. Some Blame Control, Some Blame Hydraulics, Some say there is No Problems at all! I don't know, so I report it here Only as "Hear-Say", just be aware of it. Customers that have this Machine with Fanuc-Control Option are seem Happy.

This was also Era of Strippit's Own "Windows P.C. Control", I would Avoid the P.C. Control Versions!

1250/20 and 1250XP/20 Basically, The R-Machines with Mechanical Press-Drives that were repackaged with a Larger Bridge-Frame. Good Machines if they have Fanuc-Control option, most do not.

1000/20 and 1000XP/20 Some Minor Updates and Marketing gives New Names to same old FC1000R Machines. Good Machines & Recommended, if they have Fanuc-Control Option. As "R-Family" of Machines have a Mechanical Press-Drive that does Not have Pressure Oil-Lube System of Past Machines, Grease Press-Drive Often, using a High-Quality (Mobil) Synthetic grease, or Press Bearings Wear-Out.

EARLY 1990's

FC1000S, FC1000SXP, FC1250S, FC1250SXP Machines are some of the Best Strippit Ever Built, and are Highly-Recommended! Very Heavy-Duty C-Frames, Reliable Mechanical Press-Drives with Desirable Wet (Hydraulic) Clutch & Brake Unit, and Most used Fanuc Controls with A.C. Servo Drives.

Fanuc Versions are Recommended! A few Machines were built with Odd-Ball DOS / Windows P.C. & Apple-Mac P.C. Controls, Avoid Them!!! Note That most Strippit 30-Ton Mechanical Press-Drives were Built with a Filtered Oil-Lube System for their Crankshaft, Ram, and Bearings, and these Items Last Forever. However, Amada Mechanical Press-Drives are Greased, and tend to Need a Very Expensive Rebuild and Replacement of their Press-Drive Bearings & Crankshaft Items every few Years.

FC1250M Machines. Strippit's Heavy-Duty Punch Machine, sort of replacement for Ancient FC1250/45, yet Rated at 33 Punching Tons like "S" Machines. Made in Mechanical & Hydraulic Ram Versions, I prefer Mechanical. "M" Machines are Basically "S" Machines with "Thick-Turret" Option to use Amada Long-Tooling. Plasma-Cutting & Laser-Cutting Options available. Very Good Machines, Recommended!

FC1000R & FC1250R R's were later Updated to become "XP"s (Extended Performance) Machines. Same Machines only Speeded-Up. Fanuc Versions were Good Machines, but Avoid P.C. Control Versions! Good Machines when new, but are Light-Duty Machines that are wearing-out. Very Hard to Fix P.C. Controls as most "Control" Circuit Boards ("PAC" & "Motion") & Apple MAC Parts are "Not Available"! AVOID!!!

Mid to Late 1980's

2nd Generation FC1000/3 and FC1000XT Machines are Very Good Machines. Early Versions had Fanuc GN6 Controls with D.C. Servo Drives, and good but Less-Desirable Air Clutch & Brakes. Later Versions had Fanuc OP Controls with A.C. Servo Drives, and Wet Clutch & Brake Units, both of which are more reliable. First Strippits with Auto-Index Stations. Micron Parts for these A/I Stations are No-Longer Available, ask Strippit if Engineering will Design a Retrofit to Newer A/I Versions that Can be supported.

FC1000R. Strippit goes full Circle in Entry-Level Machines. From Building Good HECC80 FC750, Then Junk Di-Acro CAP1000's, then Re-Painted Imported SPM500's & SPM750's, to Finally Designing & Building their Own Machine again, The FC1000 "R" (Rear-Address) Machines. 20-Ton Machines with Mechanical Press-Drive, made with Apple-MAC, Windows P.C., and Fanuc Controls. Fanuc is Reliable and Supportable Control. Strippit is even taking-in old Mac "R" Machines on Trade-Ins, and putting New Fanuc Controls on them, as it has become Very Hard-to-Support Windows P.C. & Apple-MAC / Servo-Drive / Motion Board / System-Software Versions / PAC I/O Board Combinations, Etc, that Strippit used over the years.