Strippit & G. E. HI-ACK Servo Drives

Machine Technologies Specializes in Strippit HECC80 CNC Turret Punch Press Machines built from about 1975 to 1987. Strippits, as well as many other NC & CNC Machine Tools of this Era,

like DiAcro, Burgmaster, Wiedemann, Monarch, Motch, Behrens, Gidding & Lewis, W. A. Whitney, Kearney & Trecker, Hardinge, Warner & Swasey, and Many Others, used the General Electric

Model 2, Model 3, & Model 3A Hi-Ack Servo Drives to Power their Machine's Motion Axis.

Many Machine Tools also used General Electric Mark Century 550, 750, 1050, & 2000 Series Numerical Controls which used these Model 2 & 3 Servo Drive Systems. These Servo Drives were widely used in

the World-Wide CNC Machine Tool Industry, as they were Well Engineered, Reliable, and Easy to Service.

Around 1987, General Electric decided to Stop Designing & Manufacturing

CNC Machine Controls & Servo Drive Systems,

and Partnered-Up with the Japanese Fanuc Company,

using Fanuc's More "American Sounding" U.S. Division, General Numeric.

This was Another Incredibly Stupid-Move by "Neutron Jack" Jack Welch,

Giving-Up & Destroying Another High-Technology Industry

That Was Invented here in the United States.

About the same Time G.E. Quit Making CNC Controls,

Strippit also Quit Making Their Own CNC Controls (the various HECC80's Controls)

and thereby Giving-Up Strippit's Big Unique Advantage of Making

Both The Machine And The Control System That Were Tailored Just For Each Other.

Machine Technologies Does Not Work on the Fanuc / General Numeric Controls, as they are Far Too Secretive with Technical Information and Schematics. They are Afraid you will Steal-It, just like they did.

While these Hi-Ack Servo Drives are now out of production, Machine Technologies has

Hundreds of Servo Drive Boards In-Stock! We have New Boards, as well as Used and Rebuilt Boards.

We also Offer a Fast Repair Service, and can usually Test & Repair your Servo Drive Boards in 3 days.

Final Testing of Drive Boards are in our Strippit HECC80 FC1000/2, FC1000/3, or FC750 Machines.

Other's Test Circuit Boards using "Bench Test" Rigs, but we feel Nothing Tests Boards Better than Running them Full-Speed in a Actual Strippit Hi-Speed CNC Turret Punch Machine!

We Stock other Servo Panel Repair Parts such as Rectifiers, Filter Capacitors, Current-Sense Resistors, Cooling Fans, Transformers, and 90 & 150 Volt Contactors. Also Stocked are Servo Motors, Motor Brushes, Resolver Feedback Package, Resolver & Motor Couplings, and many other

Servo Related Parts. Call Us on the Parts you Need!

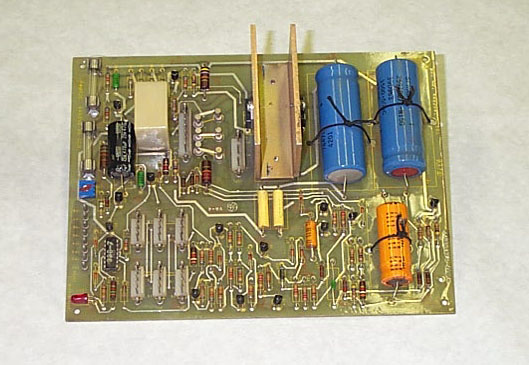

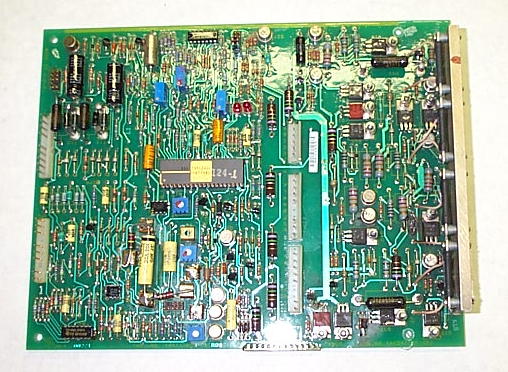

Servo Control Boards

1 of these Boards is on the Right-Side of each Servo Chassis, and Controls 1 or 2 Power-Slice Boards.

Each Boards has Special "Compensation" Resistors & Capacitors which Machine Manufacturer Engineered for that Particular Axis. If you remove it for troubleshooting or repair, TAG-IT so you can put it back into Same-Axis

on a multi-axis machine. Versions are;

P/N's 21239-000, 44A398795-G01 to 44A398795-G03

PWMC3, PWMC3A, PWMC3B, PWMC3C,

PWMC3D, PWMC3E, PWMC3F, PWMC3G

P/N's 22527-000, 44A398795-G02

PWMC4, PWMC4A, PWMC4B

There is a Red LED Fault-Light on this Board that is Normally-Off. When it is "On", it means you have a

"Over-Current" Fault in that Servo Drive. Cause is usually 1 or more of the 2 or 3 Boards in that Servo Drive being bad, bad Servo Motor, or Short-Circuit in Wiring to Servo Motor. Send us Board-Set for Testing & Repair.

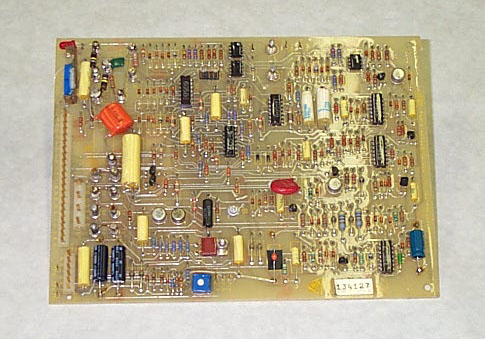

Power Modules

Sealed hi-power transistor Modules were used in the Model 3 and 3A Servo Drives, instead of Power Slice Boards used in the Model 2 Drive. 2 Modules were used in X & T axis, and 4 were used in Y axis of FC1000/3 Machines. Modules are Not Repairable.

P/N's 22648-000 44B295239-G05

There are Different Versions of theses Modules.

In the Y-Axis Drive, which uses 2-Pair

(4 Modules total), Each-Pair on Each Heat-Sink has to be the Same Version Type, so that they Share the Drive Current Equally, or else they Will Fail!

There Are Model 2 Servo Drive Failures That Can Be Prevented!

Over time, Servo Boards become Packed with Shop-Dirt blown in by the Servo Cooling Fan.

This Dirt and some Humidity can cause Short Circuits resulting in Impressive Amounts of Smoke & Flame. Capacitors and other Components also go Bad after Aging 10 years or so, causing Sudden Drive Failures.

Machine Technologies Can Do Preventative Maintenance Service On These Boards.

We Wet-Wash Circuit Boards, Replace Capacitors and other Weak Components, Add New Updates, and Finally Test Boards to Original Specs to help Prevent Expensive Servo Failures and Machine Down Time.

We can Schedule Preventative Maintenance Work over a

Weekend, Shut-Down, or Vacation Period for Minimum Production Down-Time.

Paying a Little for Preventative Maintenance Now, Can Prevent Paying a Lot in Future Breakdowns!

A smaller version of the Model 2 Hi-Ack Drives were

PWM50, PWM51, PWM91, and PWM99 Servo Drives.

These combined small Power-Slice and Control Board into 1 large Circuit Board on a Metal Chassis.

These were Lower-Power Servo Drives that were used

on Strippit FC75/30 Machines, as well as many other Machine Tools. G.E. made some Special Versions of

these Drives for Different Companies, often for

Spindle-Drives on Turning Center Machines.

P/N's 400295-100 PWM50G 44A399749-G01

PWM51 44A399749-G03

PWM99D 44A399749-G02

PWM99H 44A399749-G06

Call us on your needs,

as we still have some of these Servo Drives In-Stock.

And for those of you that are Still Paying Attention, Yes, there was a Model 1 Servo Drive System.

It apparently was G.E.'s First Attempt at a PWM-Type Servo Drive System.

It was built in the early 1970's, was quite Crude, and was redesigned into the Vastly Improved Model 2

Servo System. The Model 1 Servo was not widely used, and was never used by the Strippit Company.

This page was last updated on: 1/15/2026

The "3A" SERVO DRIVE

The "3" SERVO DRIVE

We Stock Servo Drive Repair Parts

and

Repair All Servo Drive Parts Listed Above!

Call Us on What You Need!

Call or Email Machine Technologies for

Strippit Part Pricing and Availability

Remember, We Need Your

Strippit Machine Model-Number

AND

Machine Serial-Number

AND

Strippit Part-Number

Of The Parts You Are Looking For!

Get this Information BEFORE you Call

as it's

The

FIRST--Thing

I Am Going To Ask You!

Phone 704-

233-5229

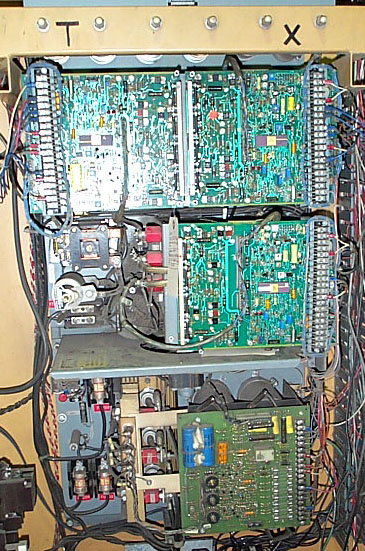

In 1980, G.E. introduced the Model 3 Hi-Ack Servo Drive.

It was a Hi-Performance 150 volt DC PWM Drive. The Higher Drive Voltage allowed Higher Servo Motor Speeds and therefore Faster Machine Axis Speeds. It had a chassis for each Axis-Drive,

with a Control Board, and 2 or 4 sealed Power Modules which Powered each Axis Servo Motor.

Strippit used Model 3's & 3A's on their HECC80 Control FC1000/3 Machines to achieve Very-Fast 3000 inch per minute X & Y axis speeds, and also used it on Some FC1500/45 Machines.

But, Some FC1500/45's used Older Model 2 Drive.

Monarch Machining Centers, Gidding & Lewis Horizontal Mills,

Hardinge, and Warner & Swasey CNC Lathes are the only other Manufacturers that I have seen, that also used Model 3 & 3A Type Servo Drive Systems. This Drive was Not widely used by CNC Industry, and Part Availability and Repairs are more Limited and Expensive, than Model 2 Servo Systems.

Early 3 Drives had Reliability Issues, were hard to work on as components access was difficult, and had a SCR Regeneration Circuit (overvoltage) that was to Backfeed Excess Current from Decelerating Axis Back into 3-Phase AC Power Lines.

This Regen Circuit was Complicated, did Not work well,

and was Very Hard to Test, Troubleshoot, and Repair.

The 3 Servo Drive was Reworked into the

Much Improved & More Reliable 3A Servo Drive.

Strippit FC1000/3 Machines with Serial Number

#066 and Above had the Improved 3A Servo Drive.

Machines Below #066 had the Original 3-Servo Drive, though a couple of Problem Machines had the old 3 Drive Replaced, in the Field,

with the Newer 3A-Servo Drive.

The Early PWMC5 Control Board on the

"Small 2-Power Module" Size 1, 2, and 3 Type "3" Drives, was Redesigned into the PWMC7 Board.

The Early PWMC6 Control Board on the

"Large 4-Power Module" Size 4 & 5 Type "3" Drives, was Redesigned into the PWMC8 Board.

All Early "3" Drives with the PWMC5 & PWMC6 Boards were Suppose to have had them Replaced

with the Newer PWMC7 & PWMC8 Boards.

Mechanical Access to Drive Parts was improved

and a much Simpler and More Reliable Overvoltage Circuit was used to replace old Regen Circuitry.

3A Drives had 1 Big Wire-Resistor

that goes Across the Top of the Servo Panel.

3 Drives had 6 Big Ribbon-Wire Power Resistors,

Side by Side, on Top Servo Panel.

Power Supply & Regeneration Board

Model 3 Drive used PSRG3 Power Supply Regen Board. This Board, 1 per Multi-axis System, supplies Low Voltage D.C. Power to Control Boards, handles Fault-Inhibits, & Controls SCR Regeneration Circuits.

The Improved Model 3A Drive used PSRG5 Power Supply Regen Board to do the same

Servo System Power, Inhibit, and Regeneration functions.

PSRG3 and PSRG5 are Completely Different Boards, and are Not Interchangeable!

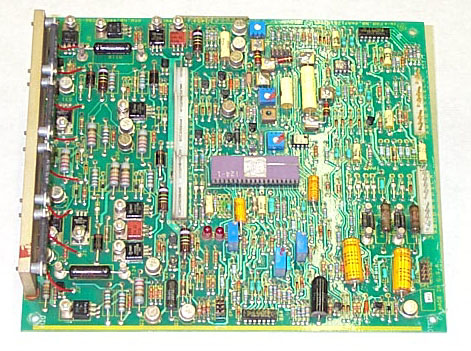

Servo Control Boards

PWMC7 Board Controls 2 Power Modules on the

Smaller X or T-Axis Servo Drive on Strippit Machines.

PWMC8 Board Controls 4 Power Modules on the Larger High-Current Y-Axis Servo Drive on Strippits.

Very Early 3 Drives (Built about 1980 to 1982) had PWMC5 and PWMC6 Control Boards. These Early Boards were So Unreliable that General Electric Redesigned PWMC5 Board into New PWMC7 Board, and PWMC6 Board was Redesigned into New PWMC8 Board.

At Strippit, We Updated ALL Early Model 3 Drives to

PWMC7 & PWMC8 Boards in the Field back in 1983

40 years ago! All Model 3A-Drives came from

Strippit Factory with New Type Boards.

Other Brands of Machine Tools that used these Old PWMC5 & PWMC6 Boards should have them Replaced

with New PWMC7 and PWMC8 Boards!!!

If you have any Old PWMC5 & PWMC6 Type Boards

laying around, Do NOT Use Them!!! They are

Unreliable and likely to Blow-Out Power Modules!!!

Replace them with New PWMC7 & PWMC8 Boards!!!

There are 2 Fault LED lights on these Boards that are Normally-Off. An LED "ON" means a "Over-Current" Fault, usually caused by, a Bad Servo Control Board, Bad Power Module, Bad Servo Motor, or Bad

(Short-Circuit) in Wiring to Motor.

There are also "False LED-Trips" sometimes on some Machines caused by Electrical-Noise from Poor Internal Machine Wiring-Layout, Bad Suppressors, or Arcing in the Machine somewhere.

These "False Trips" Can be Very Difficult to find.

Note!!! Note!!! Note!!!

There are Components on these Boards that Wear-Out in Old Age, and can cause Very Expensive Servo Failures!

Send-In your PWMC7 & PWMC8 Boards to be Updated

and Save yourself a Lot of Expensive Grief!

We can Do these Board Updates in only 2 Days!

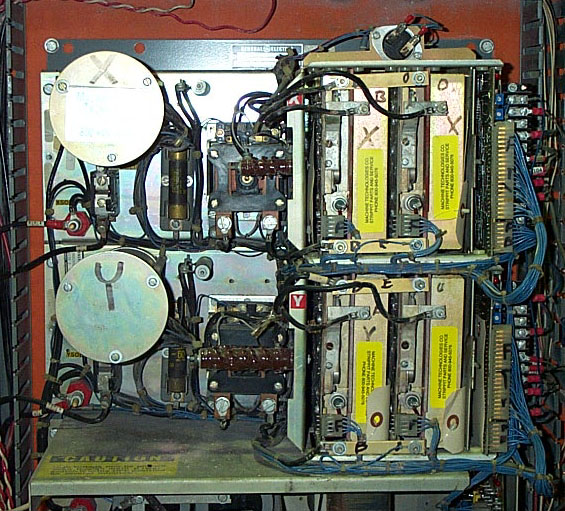

The Model 2 was a 90 volt DC PWM (Pulse Width Modulated) Servo System that was Widely Used, and was

in Production from about 1974 to the late 1980's.

Each Axis Servo Drive had its own Chassis, which held 1 or 2 Power-Slice Boards, a Control Board on Right-Side, and Various capacitors, resistors, contactors, and other miscellaneous parts. So, if you had a 3 Axis CNC Machine

(X, Y, T) you had 3 of these Chassis's Mounted on a

Back-Plate with a Power Supply Board, Cooling Fan, and other Power Supply Components

usually mounted at Chassis bottom.

Various Combinations of Power-Slice Boards were used, depending on Drive-Current Requirements of Machine Tool.

Model 2 Drives were used on following Strippit Machines;

FC750, FC750/2, FC1000, FC1000/2, FC1250/30, FC1250/45, FC1250/45/72, FC1250/30/1500, FC1250/30/1500 LASERTOOL, FC1250/30/1500 LASERCENTER, FC1500/45, BLANKING CENTER, and FC75/30.

Machine Technologies Can Supply Servo Repair Parts & Servo Board

Repairs On Any Machine Tool Using G.E. Model 2 & 3 Servo Drives!

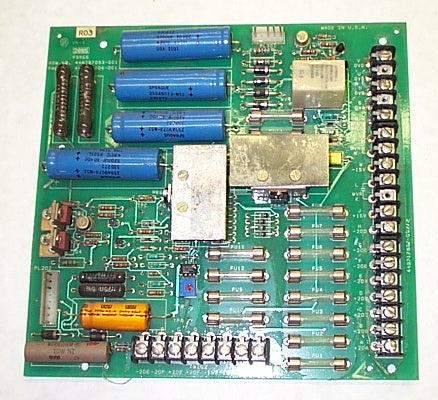

Model-2 Power-Slice Boards

These are the Boards that actually Power the Servo Motors and are Easy to identify as they all had Large Aluminum Heatsinks. 1 or 2 Boards are used in each Drive-Chassis. There are 5 Types, Sizes 1's to 5's.

As Boards were in Production for about 20+ years, they Evolved somewhat, and

Periodically the Updated Boards received New Version Names.

PWMP's are the Earlier Versions, PWMU's are the Later Underwriter Laboratory Approved Versions.

For the most part, they are all Backwards Compatible. Example, a Newer PWMU-2B could replace an

Old Original PWMP-2 Board. Following are the 5 Power-Slice Board Types;

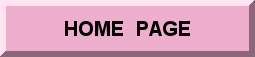

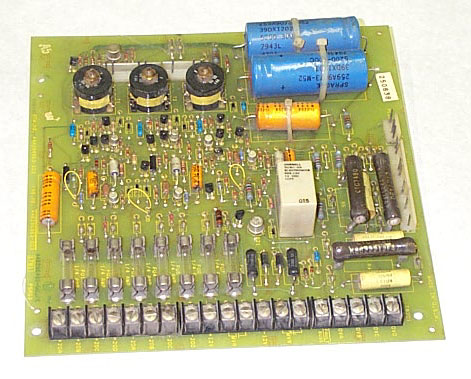

Power Supply &

MVR Relay Board

Only 1 of these per multi-axis Servo System, and it is usually located under the Bottom-Most Servo Drive.

Board Powers Control Boards (up to 6 boards) which Control Power-Slices, which Powers Axis Motors.

There are also some Inhibit Functions on this Board,

which Disables Servo Drives if there is a Voltage or Current Fault.

The Early Versions Are;

P/N's 21240-000 44A398788-G01 to 44A398788-G03

PWMR2, PWMR2A, PWMR2B, PWMR2C

And Late Versions are; P/N's 22526-000

44A398788-G04 & 44A398788-G05 PWMR3, PWMR3A

The G.E. Model 2 Hi-Ack Servo Drives

G.E. Model "3" and "3A" Hi-Ack Servo Drives

The Strippit & G.E. Part Numbers &

Model-2 Power-Slice Board "Sizes"

P/N's 21431-000, 22528-000, 44A398797-G04

PWMP1, PWMP1A, PWMP1B,

PWMU1, PWMU1A, PWMU1B

P/N's 21241-000, 22529-000, 44A398786-G08

PWMP2, PWMP2A, PWMP2B,

PWMU2, PWMU2A, PWMU2B

P/N's 21242-000, 22530-000, 44A398786-G07

PWMP3, PWMP3A, PWMP3B,

PWMU3, PWMU3A, PWMU3B

P/N's 21887-000, 22531-000, 44A399729-G07

PWMP4, PWMP4A, PWMP4B,

PWMU4, PWMU4A, PWMU4B

P/N's 21430-000, 44A399729-G08

PWMP5, PWMP5A, PWMP5B,

PWMU5, PWMU5A, PWMU5B

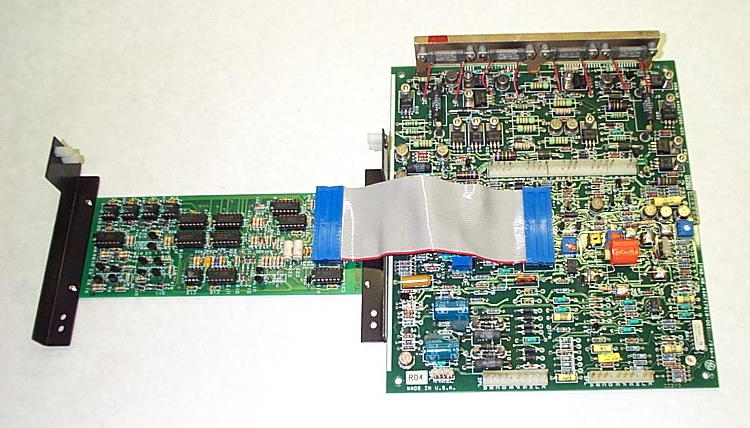

PWMC7 Servo Control Board

P/N's 22645-000 44A297086-G03

PWMC8 Servo Control Board

P/N's 22646-000 44A297087-G03

PWMC7 Servo Control Board

with New LSI-Chip Replacement Daughter-Board

As the Custom LSI-Chip that is the "Brains" of the PWMC7 & PWMC8 Servo Control Boards are No Longer Available Anywhere, A Custom "Daughter" Circuit Board was Developed to take the Chip's place.

This Daughter Board has a Ribbon Cable that Plugs into the Old LSI-Chip Socket, and does all the Functions that the LSI-Chip used to do.

Daughter Board is Mounted in Front of the PWMC7 or PWMC8

Circuit Board.

At the Right is a Photo of a

Strippit FC1000/3 Machine's

Model 3A Servo Drive

that has 2 PWMC7 Boards with Daughter Boards being used in the

T and X Axis Servo Drives at the

Topof the Servo Drive System.

A PWMC8 Board,

Without a Daughter Board,

is in Y-Servo at the Bottom.

PSRG5 Board, for 3A-Servo Drive

P/N's 22647-000 44A297093-G01

PSRG3 Board, for 3-Servo Drive

P/N's 22609-000 44A294563-G03

The Model 2 Servo Drive System, while Old, is Quite Reliable

and Repair Parts & Servo Board Repairs are Readily Available.

We Have Hundreds of Model 2 and Model 3 Servo Drive Repair Parts In-Stock!

We also Stock Model 3 & 3A Servo Parts. However, the Model 3 and 3A Servo System

is Not as Reliable, and the Parts are more Expensive and Harder to Obtain.

For these Reasons, we are Working-On a Servo Retrofit to a Newer Servo Drive System for the Strippit Model FC1000/3 Machines that should be Both More Reliable and Lower in Price.

If you have Interest in this, Call & We will Work on this Retrofit a Little Faster!

!!! Note !!!

Bad Power-Modules Can Burn-Out PWMC7 & PWMC8 Boards,

AND

Bad PWMC7 & PWMC8 Boards Can Burn-Out Power-Modules!

"Swapping" Parts Between Different Servo-Drives While

"Troubleshooting" Risks Burning-Out More Boards & Modules!!!

Send-In Your PWMC7 & PWMC8 Boards AND Modules for Testing!

A Great Cover, Drawn by Fred Kasten R.I.P.

for My Servo Drive Manual I put together for the Strippit Co.,

a Long Long Time Ago.

But Fred, Who in Hell Is The Ugly, Bald, Bearded Guy???

We Also have In-Stock a Limited Supply of

G.E. Hi-Ack Servo Drive Manuals

if you have Lost Yours.

These come in 4 Types;

--- Model 2

--- Model 2 UL

--- Model 3

--- Model 3A

You and Your Serviceman Cannot Work on Your Machine's Servo Drives Without Correct Manual!

We Do Servo Board Repairs on

PWMC7 44A297086-G03 PWMC8 44A297087-G03

PSRG5 44A297093-G01 PSRG3 44A294563-G03

and have, In-Stock, Repair Parts like

Power-Modules 44B295239-G05 & Contactors 44A399668-004

Strippit has been Telling Their Customers that

G.E. Servo Drive Parts are "Not Available".

It's Not True!

We Have Plenty of

#22648-000 Power-Module G.E. # 44B295239-G05

#22645-000 PWMC7 Board G.E. # 44A297086-G03

#22646-000 PWMC8 Board G.E. # 44A297087-G03

In-Stock!!!!