More Strippit Machine Repair Parts

We Specialize In Strippit HECC80 Electronic Control & Machine Repair Parts.

But We Do Get-In Some Miscellaneous Machine Parts for Newer Machines with

Fanuc and PC-Controls. Here are some of these Parts that are Available.

If You See Something You Need, Get-It-Quick, as these may be One-Time Deals!

Note, There Are Many New Items Added-On To Bottom Of This Page!

#802494-000 Accumulator Bladder.

Note, We Can Special Order These!

#802485-00 Hydraulic Filter

#119490-000 Ballscrew

Axis Bumper

#801987-000 1/2" Air-Oiler

#801986-000 1/2" Air-Filter

#802501-000 Hydraulic Rotary-Seal.

Note, See Info & Photos on

New-Style Rotary-Seal Below!

#802495-000 Vickers

Hydraulic Valve

#802495-000 Stilson Vac-Loc Block

#800480-000

Air Cylinder for

--- Auto-Index Lock

--- Side-Gage Pin

#803240-000 Workclamp

Air Cylinder

#800486-000

Air Cylinder for Machines that use 2-Cylinders for Each Turret Shotpin

Proximity

Sensor Switches

#803840-100

#800259-000

#801608-000

# 18576-000

#803214-000

#801051-000

# 18576-000

#800503-000

#802493-000

#710142-000

#801608-000

# 24696-000

#803432-000

#801721-000

# 18847-000

#100603-000

#803724-000

# 19940-000

#1000391-000

Loader / Unloader

Vacuum Cups

#107808-100

3 1/2" Tool Lifter

# ???

3 1/2" Tool Lifter

#119711-000

Auto-Index

Tool Lifter

Many Special

Oil

&

Grease

Seals

This page was last updated: January 15, 2026

Micron #45-307-526-1830

Rotary-Switch Assembly

which is

Strippit #802029-000

And is

Used on the

Auto-Index Turret Stations

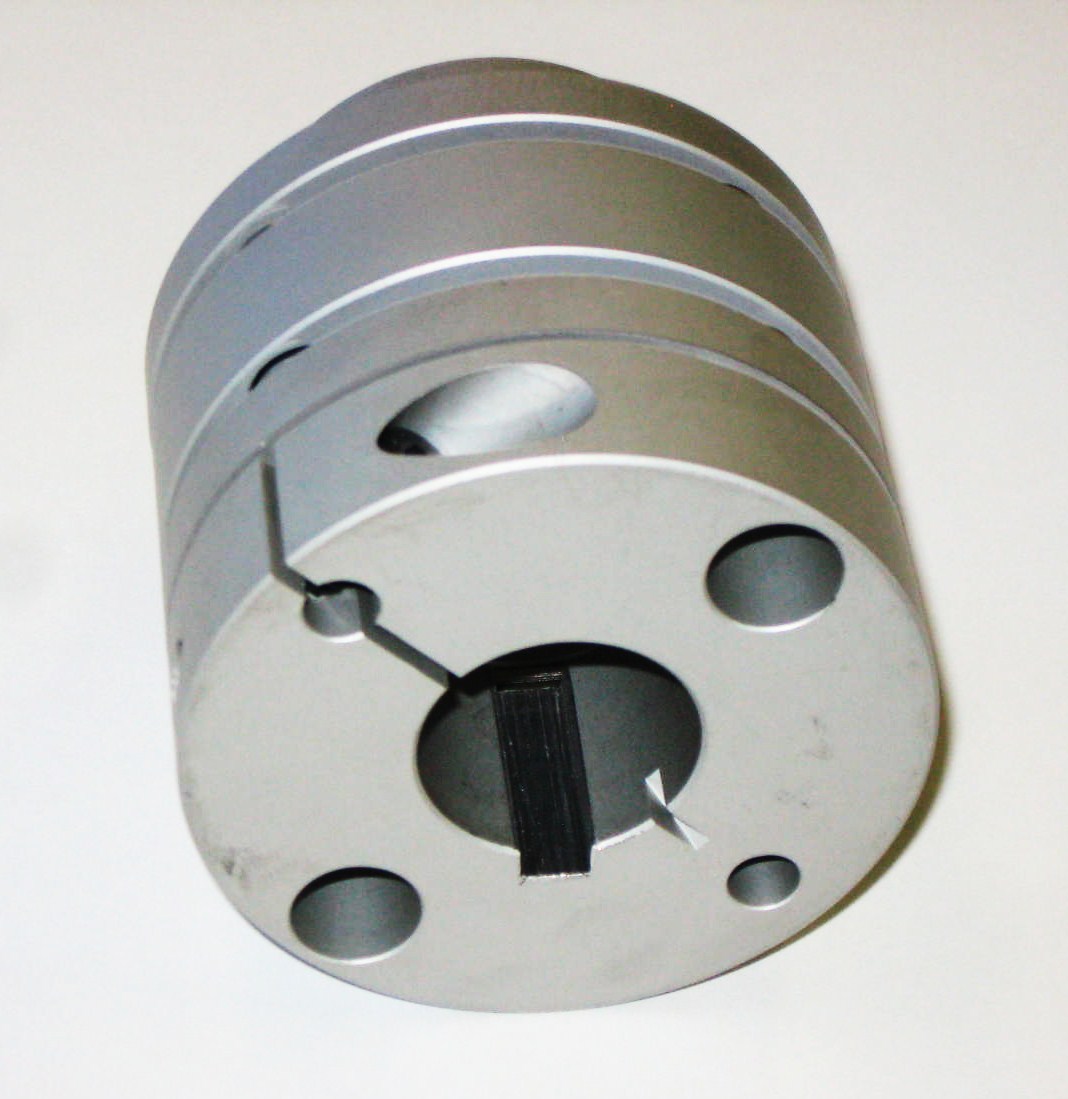

Above is Strippit Part Number #107727-100 Auto-Index Coupling.

2 are Used (1 on Upper-Turret & 1 on Lower-Turret)

to Engage A/I Gearboxes for Auto-Index Turret Stations.

We have these Special #107727-100 Couplings In-Stock!

Strippit FC1000R Parts

I have a Customer that had a FC1000R Machine with Strippit's Crappy Apple MAC PC Control. He had so much trouble with this "Control", he finally paid Strippit to do their Fanuc Control Retrofit that they offer.

Strippit "Keeps" the Old PC Control so they can resell the Boards in it to other "R" Customers so they can make Money off of you in 2 ways.

In Strippit's Defense, this Customer is Happy with the Fanuc Control Retrofit, so far, and feels that Strippit did a Good Job of doing this Retrofit.

Customer also had a few Spare Parts that Strippit did not get, so we will offer them to you here.

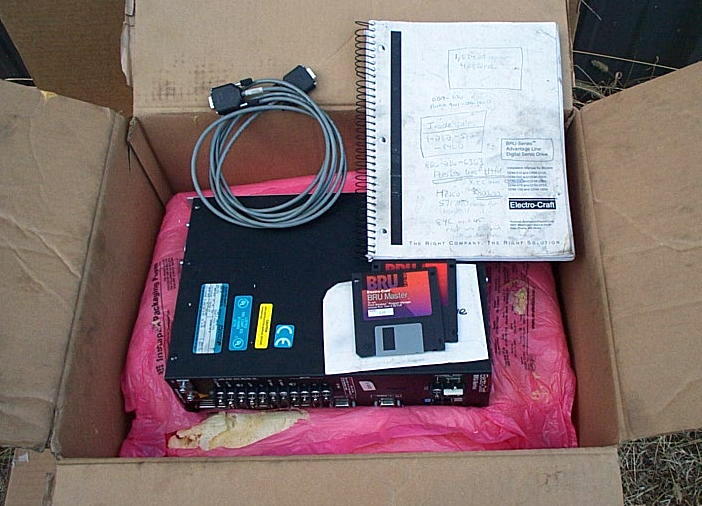

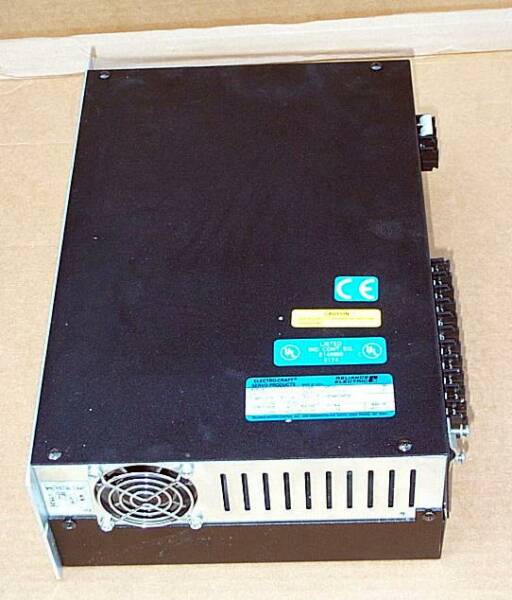

Servo Drive for X or Y Axis.

Reliance Electric / Electro-Craft

Model #DDM-030 Part #9101-1396

This Drive comes with

-- Software Set-Up Disks,

-- Software PC Download Cable

-- 500 page User Manual.

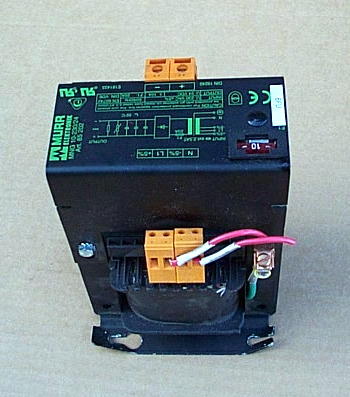

Murr Elektronik Power Supply

MNG. 10-230/24

Input 230 VAC

Output 24 VDC @ 10 Amp.

Baldor 3-Phase Turret Drive Motor

2 HP

208 / 230 / 460 VAC

1725 RPM

Sold!

Sold!

Strippit Part #802502-000

New Industrial #210415

Disk-Pack Set

(6 Friction & 5 Steel-Spacer)

This Pac Can Used on

Either of the

Clutch-Side or Brake-Side of

Strippit FC1000R Machines's

Hydraulic #211535 Clutch/Brake Unit.

Can Also Used on

Brake-Side of Strippit

FC1000S

FC1250S

FC1000SXP

FC1250SXP

FC1250M

Machine's Hydraulic

#211945 Clutch/Brake Unit

Strippit Part #802503-000

New Industrial #210410

Disk-Pack Set

(8 Friction & 7 Steel-Spacer)

Used on

Clutch-Side of Strippit

FC1000S

FC1250S

FC1000SXP

FC1250SXP

FC1250M

Machine's

Hydraulic #211945 Clutch/Brake Unit

Grinding Wheels

If you have a Strippit #85010-000 or #72150-000 Tool-Sharpener Machine,

like Shown Above,

Then you will Need New Grinding Wheels from Time to Time.

Unfortunately, Strippit now Sells Only Crappy Imported Wheels

that have Less Abrasive-Material than Original Wheels,

and use a Very Poor Binder-Glue,

so they are "Soft" And "Wear Out" Very Fast!

We Now Supply these Special-Size

Original #12359-000 Grinding Wheels

If you want a Top-Quality Grinder Wheel for your Strippit Tool Sharpener,

Give Us a Call!

We are The-Only-Source for these Special-Size Grinding Wheels

Sold!

Sold!

Special Fanuc Control Parts

Does the Keyboard Overlay on your Fanuc OP Control look like One Above?

Then You Need to Replace It! Why? Two Reasons;

1 -- The Operator or Maintenance Technician could easily Press Wrong Key,

Causing loss or Corruption of your Part Programs. Or Worse, Loss of a

Control Parameter, in which case Machine would NOT Run until Repaired!

2 -- Oil & Dirt can Enter Control causing Failure of Expensive

Keyboard and Other Control Parts.

Below is Picture of Same Fanuc Control, after Replacement with New

Special Strippit-Type Fanuc OP Overlay. We have this Special Part In-Stock!

Did Your Knuckle-Head Fork-Lift Operator Run into Your Machine? Again?

Then you better Fix the Servo Motor-End before CNC Control

"Loses Feedback Position" and Axis "Runs Away" which could Damage Servo Motor, Servo Drive, and Ballscrew. Not to Mention, a Big Safety Hazard as Someone could get Hurt Badly if Caught in the "Runaway"!

This particular Fanuc Servo Motor simply needs Motor End-Cap Replaced and Feedback Cable Connectors Remounted on New Cap.

New Motor Caps come in Several Different Sizes. To get Correct Cap,

we will Need Data off of Motor I.D. Plate on Side of Damaged Motor.

We Also Have

7-Key "Softkey" Overlay for the "SoftKey Keyboard"

which is Located Under CRT-Monitor Display.

NOTE! We have ONLY 1 Set Left, So Act Fast!

#802501-000

Hydraulic Clutch & Brake QRV Rotary-Valve

In Late 1980's and most of 1990's, Strippit Switched from Air Clutch & Brakes on their Mechanical Press-Drive CNC Machines, to using a Combination Hydraulic Clutch & Brake Assembly.

1 -- Had Drip Catch-Ring Inside-Diameter Hole Opened-Up on a Lathe, so that

Rotary-Valve could Not Touch it.

2 -- Scrapped away most of old RTV.

3 -- Installed New-Style Rotary-Valve.

Note, when Installing Valve, Very Carefully install Hydraulic Hose Fitting on Valve Before Mounting on Machine. This is to Prevent Excessive Side-Thrust on Valve which can Permanently Damage it! New-Style Valve does Not have Grease Fittings like Old Valve.

Real Problem with This Machine is

Crankshaft Bearings are Worn-Out which allows Crankshaft to Sag Down from Original Position and will Break Parts & Leak oil until Pressdrive is Rebuilt !

This is The Problem with ALL R-Type Machines as Cheap-Ass Strippit

Grease System DOES NOT WORK!

R & XP Machine Ballscrew Couplings

In Early 1980's, Strippit Solved a Persistent Machine Problem with Keyed-Ballscrew Couplings by Upgrading to New Keyless-Couplings which did Not get Sloppy Loose Keys, and Fall-Apart.

In 1990, Strippit Introduced the R & XP Machines. To make Machines Cheaper, Strippit Stupidly went Backwards to Old Keyed-Couplings again, and "Duh!", Same Old Problems came Back.

If you have Loose, Broken, Falling-Apart Ballscrew Couplings causing Tolerance Problems or Worse, Replace it with Our Keyless-Coupling, which has 2 Advantages;

1 -- It has a Higher Tork-Rating than Original Coupling, making it Much more Durable.

2 -- It Clamps onto Motor & Ballscrew Shafts, even if Shafts are "Less than Perfect"

from Damage caused by Old Coupling.

Just Clean-Up any Burrs & Rough-Spots on Shafts with a Flat-File, Slide Coupling On Shafts,

Center Coupling Between Shafts, and Tighten Lock-Collars at each end.

No More Keys to Fit & Install. No more Keys to Rock Back & Forth and get Loose.

There are Many Misprint-Mistakes in Strippit's Part Manuals. In 1 "R-Machine" Parts Manual, this Same X & Y Axis Ballscrew Coupling is Listed as #120823-000, #120832-000, and #120382-000 !

To make Sure you get Correct Coupling, Measure Both Your Motor & Ballscrew Shafts.

Most of these Machines have .750" Motor-Shaft and .718" Ballscrew-Shaft Diameters,

and that is the Coupling we Stock, though we can Make any Coupling you might want.

Below Photo, New Keyless-Coupling on Left, Old Keyed-Coupling on Right.

Especially on R-Type Machines, Clutch-Brake Assembly and Rotary Valves had a Tendency to Leak Hydraulic Fluid. Rather than Fix Problem, Strippit Installed Mechanical "Band-Aid" Catch-Ring which was suppose to Collect Fluid Drips and Pipe them back to Tank through lower Black-Tube in Photo.

Look at Gap at Top of QRV-Valve and Bottom

of Valve on this 1000R. Strippit went Cheap on

All R-Machines and used a Simple Manual or Semi-Auto Grease System instead of their Old Excellent Earlier Pressure Oil Lube System on Crankshaft Bearings. Grease System did NOT work worth a Crap & allowes Bearings to Wear-Out. Have seen Machines with 3/8" (.375") of Bearing Slop. New Machines have about .008" Bearing Clearance. Crankshaft Flops Around with Every Punch Damageing Clutch-Brake Seals & Internal Parts & QRV-Valve. Eventually Pitman Breaks. For Thousands of Dollars you Rebuild Press-Drive & start over again.

This Customer added Orange RTV-Silicon everywhere, as if that would help.

We Stock

New #802501-000

New-Style

QRV Rotary-Valve

which is a

Direct Replacement

for the Old-Style Valve

which is

Not Made Anymore.

Grinding Wheels

Sold!

Magnetic Limit Switches

In the 1980's & 1990's, Strippit used Magnetic Limit Switches on most Machines for

X & Y & T-Axis Slow-Down, Zero, and Over-Travel Switch Functions. Sometimes

on Tool Doors also. Most of these Switches were 1 of the following 3 Part Numbers.

They are All the Same Switch, Normally-Open But Held-Closed By Magnet,

with just Different Cable Lengths;

#19149-000 Normally-Open Switch with 3 Foot Cable

#19146-000 Normally-Open Switch with 9 Foot Cable

#800435-000 Normally-Open Switch with 16 Foot Cable

We Stock the

#800435-000 Normally-Open Limit Switch, Used for All 3 Above Part Numbers.

-------------------------------------------------------------------------------------------------------------------------

There is also 1 other Odd Magnetic Limit Switch Strippit used on Many Machines that Used Fanuc GN6 Control. This is a Normally-Closed But Held-Open By Magnet Switch that was mainly used for the Turret-Zero Switch.

#801111-000 Normally-Closed Switch, The Opposite of #800435-000 !

We also Stock this #801111-000 Normally-Closed Switch.

Note, All Our Switches also Come-With The Matching #19147-000 Magnet!

I/O Modules

Many Strippit Machines using Fanuc CNC Controls used Various I/O Modules.

Input-Modules are used to Isolate and Condition Machine Switch Signals going into Control. Modules would Typically be Marked "IDC24" or Similar.

Output-Modules are used by Control to Power Solenoid Valves and other External Devices. Modules would Typically be Marked "ODC24", "OAC24" or Similar.

We can Supply all of these Modules.

While the Strippit Part Number is Helpful, Strippit's Manuals often have Part Number Errors, so we Need You to

Read Numbers off of The Module to insure

that we Supply you Correct Module.

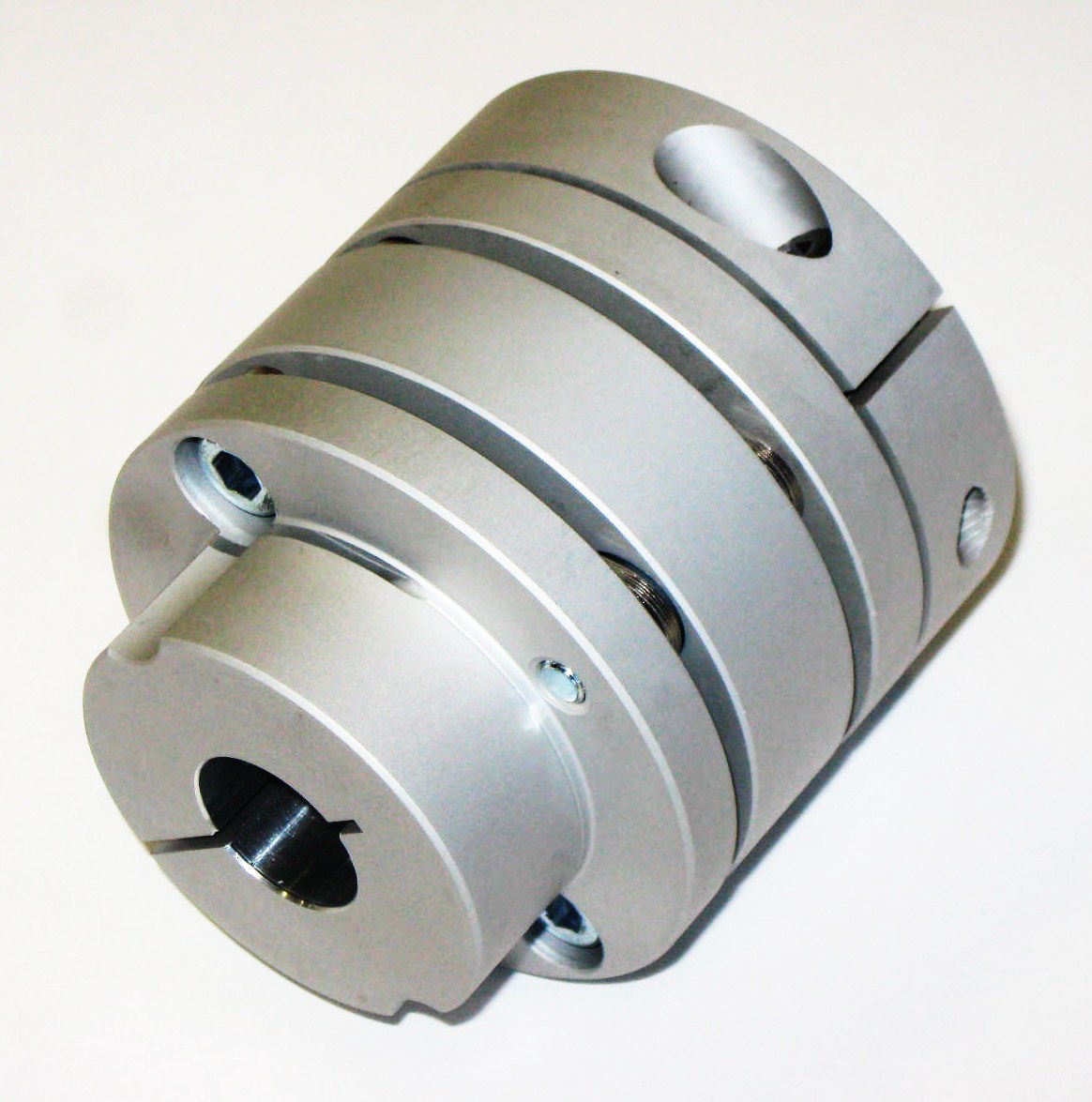

S-Machine Ballscrew Couplings

In 1990's, Strippit introduced the S-Machines. Some Models in this Class of Machine are; 1000S, 1000SX, 1000SXP, 1000SXP/30, 1250S, 1250SXP, 1250SXP/30, 1250M, 1250MH, 1250MXP/30, among others. Excellent Machines using a Keyless "Ring-Fetter" Coupling which worked well.

However, if it did get loose from Crashes, it could tear itself Apart before Operator would notice.

Strippit Engineering Stupidity did Not have "Limit" Switches on Ends of X & Y Axis of S-Machines, so you Could "Crash" Ballscrew Hard into End of X or Y Carriage under some circumstances!

Rumor has-it that Strippit did not want to Pay-For another I/O Board in the Fanuc Control, so they Just "Eliminated" Axis Protection that had been considered Necessary for the prior 30 years!

If you have a Loose, Broken, Falling-Apart Ballscrew Coupling causing Tolerance Problems, or Worse, Replace it with Our Keyless-Coupling, which has 3 Advantages;

1 -- It does Not Cost Strippit's Normal "All Of Your Money and Your Arm & Leg" Pricing.

2 -- It has a Higher Tork-Rating than Original Coupling, making it More Durable.

3 -- It Very-Easily Clamps onto Motor & Ballscrew Shafts, even if Shafts are "Less than Perfect" from Damage caused by Old Coupling. Just Clean-Up any Burrs & Rough-Spots on Shafts with a Flat-File, Slide Coupling On Shafts, Center Coupling Between Shafts, and Tighten just 1-Screw on Lock-Collar at each end, and you are Done. Very Quick & Easy to Install! No Bazillion Strippit-Type Coupling Parts to Assemble! No Keys to Fit & Install, or to get Loose.

To make Sure you get Correct Coupling, Measure Both Your Motor & Ballscrew Shafts.

Most of these Machines have 1.375" Fanuc Motor-Shaft and .750" Ballscrew-Shaft Diameters.

Custom Couplings

We also Design and Manufacture Custom Couplings

for Any Strippit Machine,

and for

Any Other Machine Tool also!

Simply Provide;

--- Both End-Shaft Sizes.

--- Motor Stall-Tork Rating,

Read it off of the Motor I.D. Plate.

--- Custom Couplings take 3 to 4

Weeks to Manufacture, so Order

your New Coupling Before Your

Old Coupling Fails Completely!

Tooth-Belts

#803402-000 R-Machine

Turret Drive Belt

#802038-000 Auto-Index

Rotary Limit-Switch Belt

#801664-000 Auto-Index

Drive Belt for FC1000/3,

S-Machines, M-Machines

#803445-000 Auto-Index

Drive Belt for R-Machines

FUJI Electric

Twin-Transistor

Power-Module

#EVK31-050A

50 Amp. 500 Volt

Modules are used in some Fanuc & General Numeric Servo Drives as well as many other applications.

These are NEW

Un-Used Old-Stock.

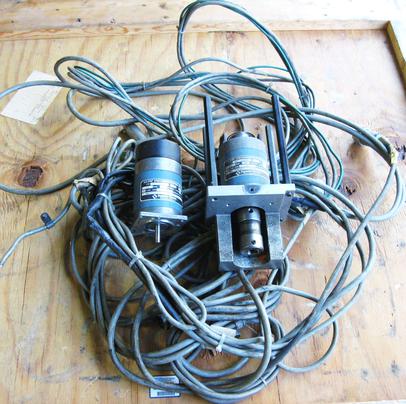

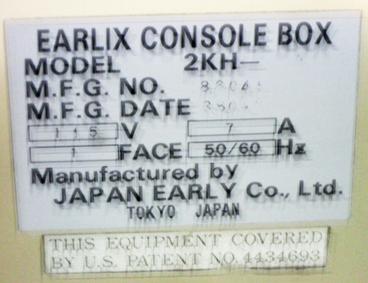

Strippit "AG" Autogage Control System.

18/30AG and 30/30AG Strippit Single-Punch Machines used this Earlix Control System. We Pulled this Control and 2 Stepper Motors off of a Damaged Machine.

As Earlix Co. is Out-Of-Business you should Buy this System so that you have Spare Repair Parts to Repair Your Machine.

Fanuc Servo-Motor

R & XP Machine Ballscrew Couplings

Over 90% of R & XP Machines used Strippit's Crappy CNC Controls based on Apple-MAC or

IBM-PC Personal Computers. Strippit did offer, as Extra Cost Option, a Industrial Quality Fanuc CNC Control & Servo-Drives & Servo-Motors, but few were sold as Machine Buyers went Cheap.

Congratulate yourself if you were smart enough to have bought your Machine with Fanuc Control.

But Strippit Stupidly used the same Crappy Coupling Type that will fall apart eventually.

Our Coupling Retrofit show in Above Photos will Not fit, as the Fanuc Motors used had

Odd Tapered-Shafts. To Compensate for this, Strippit Manufactured a 1.000" Outside Diameter Adapter Bushing that Fit Over Motor Tapered-Shaft and which also had a Lock-Nut on end of shaft.

We now offer, a Custom Coupling Retrofit for these Fanuc Control Machines that fits the same

.718" Ballscrew-End and also fits over the 1.000" Strippit Adapter-Bushing-End, which is retained.

See the 2 Fanuc Coupling Photos Below.

There are Many Misprint-Mistakes in Strippit's Part Manuals.

So to make Sure you get Correct Coupling, Measure Both Your Motor & Ballscrew Shafts!

Sold!

I have In-Stock,

and

For-Sale

1 Good-Used

Strippit

#85010-000

Tool-Sharpener Machine

I have Personally taken apart

and Cleaned the

Feed-Mechanism and the

Tool-Chuck

so they Both

work Smoothly.

It has a Good

Grind-Wheel

Installed

and has the

Chuck-Key.

I Rarely have these For-Sale

so if you want a Good Strippit

Tool-Sharpener

Act-Fast

as I only have

this 1!