Strippit Houdaille HECC80 Control Types,

Some Common Problems & Fixes,

and Other Strippit Control Types.

Many People (Salesmen, Servicemen, and Customers) Bandy-About the Name

"HECC80 Control", which has become sort of a Generic Term for Older

Strippit CNC Controls. But these People Rarely know what they are Taking About.

Some People even call the Ancient NC Hard-Wired "A Controls", HECC80's,

which they Certainly Are Not!

For You To Properly Evaluate, Operate, & Service Your HECC80 Control,

You Need To Know Exactly What TYPE of HECC80 Control It Really Is!

HECC80 is a Acronym for "Houdaille Electronics Computer Control"

and the 80 is from Intel 8080 Microprocessor that was First Used in them.

There are 2 Main-Types of HECC80 Controls.

For Clarity, We will call the First-Type HECC80/1 Controls,

and the Second-Type HECC80/3 Controls.

HECC80/1 CONTROLS

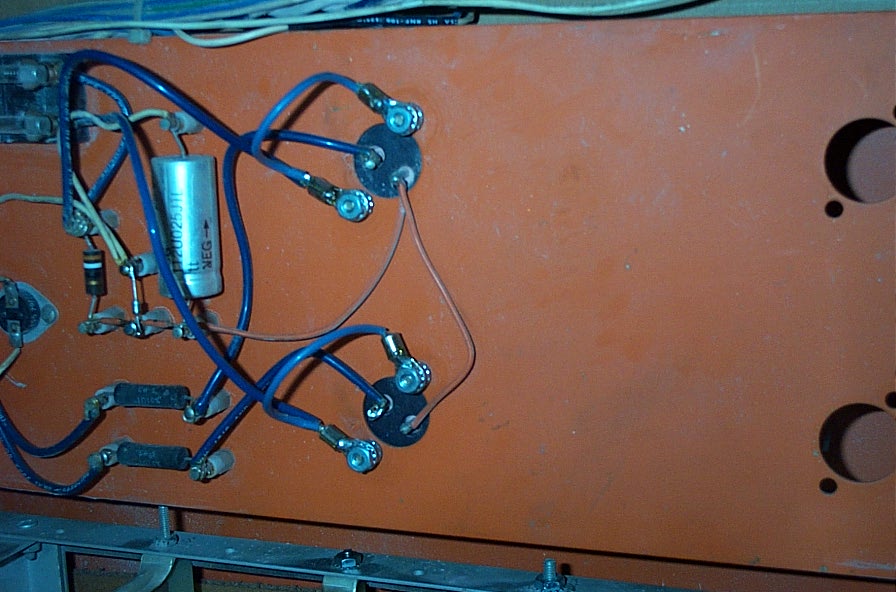

--- Pre-Regulator Panel

Pre-Regulator takes Raw D.C. Voltage (about 12 to 13 VDC) from Floor-Plate Assembly, Pre-Regulates it to a Clean Voltage (about 8.5 to 9 VDC) before sending it to Each Circuit Board's 5 Volt Regulator in Card-Cage Assembly. Without Clean 5 volt Power to Chips, anything can Happen.

The 2 Power-Transistors Mounted on Pre-Regulator Panel get Raw DC Power through a Wire & Ring-Terminal on 1 of 2 Mounting-Screws. Over time, Insulation underneath Crumbles and Connections gets Loose, Corroded, and Electrically Intermittent. We put additional Nylon Insulator Washer on Screw, Solder (Not Crimped!) a New Ring-Terminal on Wire with a Second Wire & Ring-Terminal to Loop-Over to other Mounting-Screw, so Transistors Now get DC Power from Both Mounting-Screws.

Repeat for other Transistor. Work Needs to be done by a Good Technician.

First Type of HECC80 Controls are commonly called the HECC80/1. They are easy to distinguish by 1-Line Self-Scan Display Unit and small Keypad used for Data-Entry, like Control pictured at left.

A Great Advantage for Strippit, to Design & Manufacture Their Own Custom CNC Controls for Their Punch Machines. Houdaille Electronics was 5 miles up the road and was really Part of Strippit.

All of HECC80/1 Type Controls are closely related, and many of their Circuit Boards are interchangeable, But Not All!

Great effort was made by Engineering, but this was a big project for a small Company, and development was a bit slow. To put it in Proper-Context, Strippit Shipped their CNC HECC80 Control 5 years Before

IBM shipped their First PC Computer!

HECC80/3 CONTROLS

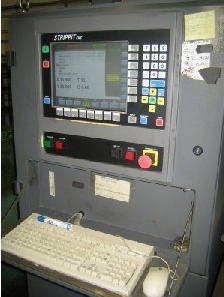

The Second Major Type of

HECC80 Controls We will call the

HECC80/3 Controls,

though HECC80/30x

would be more Accurate.

Easily Identified by the

12 inch CRT Monitor Display

and Full Keyboard

as shown in the Picture at left.

That's the Machine Technologies Replacement Keyboard

shown in Picture,

as the Original Microswitch

Keyboard has Failed.

The Family of HECC80/3 Controls are also Closely related to each other.

There are

8 Types of these Controls;

--- HECC80/3 First of this series of Control, used only on Early FC1000/3 Machines. Featured Intel 8085 Microprocessors on 2 CPU Boards in Slots 2 & 10, CRT Display, 32K of Ram Memory with Battery Back-up, full Keyboard, and the G.E. Model 3 Servo for High Axis Speed (3000 IPM).

Most of these Controls were later Retrofitted in the field to HECC80/302 Status, to get the

Advantages of Later-Control Type Bubble-Memory Board.

Around 30 of these Controls were build in 1981 to 1982. Control uses #401300-000 Schematics.

--- HECC80/302 Basically an Updated HECC80/3 Control used only on FC1000/3 Machines.

L6 Prom Board was replaced with #401350-000 256K Bubble Memory Board which provide 128K of Memory for Customer's Part-Programs and 128K for Machine & Control Executive Run-Programs that ran Machine. Ram-Memory upgraded to 48K using 3 -- 16K Ram Boards in Slots L3, L4, & L5 on early Controls and 1 -- 48K Ram in Slot L3 on later Controls. Servo Drives upgraded from G.E. 3 Drive to Much improved G.E. 3A Drive. Built from 1982 to 1986, uses #401473-000 Schematics.

--- HECC80/302 Conversion A Ram and Bubble Board Upgrade to Convert, in the field,

a HECC80/3 Control to a HECC80/302 Control. Most HECC80/3 Controls were Converted to HECC80/302 Control status in 1982 to 1984 by Dandy Don Dahlin (R.I.P.) and his Merry-Men.

But a few were Never Converted. Conversion uses #401522-000 Schematics. To further Confuse, these is also a HECC80/302 RETRO Schematic #401660-000 which adds More Updates like

Phase-Monitor, Power-Fail Diode, Etc.

--- HECC80/302A A Updated HECC80/302 Control to Latest-Style Circuit Boards for Improved Reliability. Used only on the "Reliability" Series FC1000/3 Machines which also had many Mechanical Improvements and began with Machine Serial #200. FC1000/3's with 302A Controls are Best of HECC80/30x Control Machines. Made 1984 to 1986, uses #401722-000 Schematics.

--- HECC80/304 Basically HECC80/302 Control mounded in a Stand-Alone Cabinet with special Software & Proms and I/O boards for use on FC1500/45 Punch & Plasma Machine. Oddly, Strippit built these Controls first using G.E. Model 3A Servo-Drives And later-on using Model 2 Servo-Drives, which are Very Different! Built 1983 to 1986, uses #401470-000 Schematics.

--- HECC80/306 Basically a HECC80/302 Control mounted in a Stand-Alone Cabinet with Special Software & Proms and I/O boards for use on FC1250/30/1500 and FC1250/30/1500 Laser-Tool Machines. Used G.E. Model 2 Servos only. Built 1983 to 1986, uses #401592-000 Schematics.

--- HECC80/BC Basically a HECC80/302 Control mounted in a stand-alone Cabinet.

Had a Special CRT Graphics Board, Software, and I/O to run the Blanking Center Machine.

Blanking Center was a FC1250/30/1500 Table-Assembly Mated to a Herr-Voss Shear to make a

CNC Right-Angle Shear Machine for Stand-Alone Operation, and Punch-Machine Cell-Systems.

Used G.E. Model 2 Hi-Ack Servo. Built 1983 to 1986, used #401359-000 Schematics.

--- HECC80/2 There was also a couple of HECC80/2 Controls build around 1980.

These were Special Controls that were Custom-Made for a New Caterpillar Co. Plant that was

being built with all Machines being DMC (Central-Office) Controlled.

These Early Specials became the Basis for this HECC80/30x family of Controls.

These Custom Controls probably do not exist anymore. Schematics #???

Note, All HECC80/3 Controls had a Simple "FAB-5" Macro Programming Language Built-In.

Old Part-Programs Written using these Macro's will ONLY Run on HECC80/3 Controls, and these Macro's are NOT Supported by Any other CNC-Control or CAD/CAM Programming System.

For More Common HECC80/30x Control Problems,

Please Check-Out the "Bubble Board Adjustment & Fixes" Web Page.

This page was last updated: January 23, 2026

Original

Floor-Plate

Stud-Diodes

Mounted on Painted-Steel "Heatsink"

What were those Idiots

Thinking???

Our Rework on the Floor-Plate with

New Stud-Diodes,

New Insulators,

New Aluminum Heatsink,

New Soldered-On Ring-Terminals,

and

New Wires

Original Pre-Regular Panel

Our Rework, New Wires & Connections

For Identification and Historical Purposes,

This is one of The NC

(Numerical Control)

"A" Controls that Predates CNC HECC80 Controls built by the now Defunct

Houdaille Electronics Division of the Defunct

Houdaille Corporation.

Again, People Mistakenly call All of these NC Controls,

"A" Controls, Which They Are Not, because they don't know any better,

and don't really care.

The A's were Very Good NC Controls (30S3, 30S4, and HC are Older & Much less desirable) from that Pre-CNC Era, and I still have a few that I keep running at some of my Customer's Shops.

But their Time has Passed, and are becoming Hard To Support. There are only about

3 Servicemen (Including myself) here in the U.S. (and None Overseas) that I consider Competent to work on them. If you are located far from us, you will Not be able to keep them Running from a Lack of Good Service & Parts.

For these reasons, I Recommend my Customer's Scrap their "A" Control Machines, and Upgrade to Newer CNC Control Machines, which Offer More Features, Better Reliability, and Better Service & Parts Availably.

And I Do Not-Recommend Anyone Buy a NC "A" Control Machine these days,

No Matter how Enticing "Cheap" Price may be, for the above Listed Reasons!

--- HECC80 This is Original HECC80 Control. Only about 50 were made in late 1978 to 1979. Had NO Memory, it ran off of Paper-Tapes like a old NC Control! This is because Marketing Dept. said "Ship It" even though Engineering was still designing it! Had 1 Prom Board for storing Machine & Control Executive-Run Program. Monitor Boards did not Monitor Control Voltages, as they did not work yet. This is why early Controls would Burn-Up Components like Tapereaders and Circuit Boards, because Monitor Boards did Not Shut-Off Control when a Power Supply Failed, like it was suppose to. This is where HECC80 got its Bad Reputation & some Servicemen called it the

"Belch-Fire 80". Control was Rapidly Improved by Engineering Dept.. and became a very good Control, but Damage to it's Reputation was done. Original HECC80's used #400575-000

Schematics. Most Early HECC80's were later Upgraded with 2 Prom and 2 Memory Boards to HECC80/1 Status, but there is still a couple of Original HECC80's around.

--- HECC80/1 This is an Improved & Upgraded HECC80, built 1979 to 1981. Had 2 Prom boards (HECC80/1 Software) to hold more advanced Executive Machine & Control Run program. Had 2 Memory Boards to allow Edit & Storing of Part-Run Programs, and was a true CNC Control. Later HECC80/1's had Resolver Excitation Board Upgrades from 2 MHZ to 3 MHZ for better Servo Tuning & Response & Positioning-Accuracy. Many Internal Improvements were also made to Control for greater Control Reliability, including a 6000 BTU Air Conditioner fitted to back of Control to get rid of Heat. HECC80/1 Controls used the #400875-000 Schematic sets.

--- HECC80/102 An Updated HECC80/1 Control to allow faster Axis Speed and a higher Punch Hit-Rate. Mainly a Software Change (HECC80/102 Proms) to allow higher hit-rate, and new Position Comparator Board Changes for same reason. Late HECC80/102 Controls had a 3 MHZ Sine-Wave Excitation Board which made a Big Improvement in Accuracy & Servo Response necessitated by HECC80 Controls being used on Laser Machines. I often put HECC80/1 Prom Boards in HECC80/102 Controls because I find Machines work better at the slightly Slower Punch & Axis Speed. HECC80/102 were built from 1981 to1986, and used #401290-000 Schematics.

The Last HECC80/102 Control was on Last FC1000/2 Machine S/N 454021086, built in 1986,

which is interesting as the New-Model FC1000/3 Machines were first shipped 5 years Earlier!

--- HECC80/750 A Repackaged HECC80/1 Control with only 2 Servo-Drives (X & Y Axis),

used only on FC750 Machines. Has special Lamp & Control Driver (-300 Type) Board and special

FC750 Software on the 2 Prom Boards that will only work on FC750 & FC750/2 Machines.

Built 1979 to 1980, uses #400727-000 Schematics.

--- HECC80/752 Updated HECC80/750 Control with Prom Software, Position Comparator, and Resolver Excitation Board Upgrades to make Machine Move & Punch Faster. I prefer HECC80/750 Prom Boards in FC752 Machines, because Machines work Better going Slower. Built 1981 to 1986, uses #401275-000 Schematics. I believe Last FC750/2 Machine was s/n 195050586 built in 1986.

--- HECC80/LC Control for Laser-Center, which was a FC1250/30/1500 Punch & Laser-Tool Machine, but without the Punch & Turret, and was a Laser-Only Machine. Basically a HECC80/1 Control without Turret Servo Drive Electronics. Special HECC80/LC Prom Boards.

Only about 6 of these Controls were built. Built 1980 to 1982, uses #401239-000 Schematics.

--- HECC80/28 Final Type of HECC80/1 Series. This was Special Version of HECC80/1 & HECC80/102 Controls for Laser Tool Machines & Load / Unload Machines. Also used for first few

(about 11) FC1250/30/1500 Punch Machines with 33-Station Turrets as New HECC80/306 Control being built for it, was not yet ready. Engineering needed to make Software Additions to Machine & Control Executive-Run Program to add Laser Improvements, but the 24K of Storage Space in 2 Prom Boards were not sufficient for this. So 4K of Ram Memory Space was Stolen from Ram #1 Board (Ram was now 20K Total) and added to Prom #2 Board for a total of 28K of Prom Program space, hence HECC80/28 Name. Some earlier HECC80/1 & HECC80/102 Controls on Laser Tool Machines were Retrofitted in the Field to HECC80/28 Status. Build from 1981 to 1986. Use HECC80/1 & HECC80/102 Schematics & "Speed Attenuation Retrofit" Print #401352-888 on these Controls as Strippit Managment was Too-Cheap to make a set of HECC80/28 Schematics!

Note, All HECC80/1 Controls had Simple "Pattern-Repeat" Macro Programming Language Built-In.

Old Part-Programs Written using these Macro's will Only Run on HECC80/1 Controls, and these Macro's are NOT Supported by Any Other CNC-Control or CAD/CAM Programming System.

--- "Control Shuts Itself Off 2 Seconds After it is Turned-On"

This is the Most Common HECC80/1 Control Problem there is.

Master-Monitor & Slave-Monitor Boards Check All DC Power Supply Voltages Continuously after

Control is Turned-On. If one or more Voltages are Too-High or Too-Low, Monitor Boards will turn

Control-Off to prevent possible damage. After Control Shut-Off, a Red LED-Light should be ON

on the Master-Monitor (S2-Slot) or Slave-Monitor (S1-Slot) Board.

If LED-Light is ON on the Master-Monitor Board, Most Common Causes are;

1 --- An Electrical-Short on Machine. Check for Smashed No-Punch Zone Sensor on X-axis, Other

Smashed Sensors & Switches, Cut or Nicked Wires, Etc. Ohm-Out your VDC (Machine 24 VDC)

to LVR (Low Voltage Return-Ground) and 1DC (Machine 12 VDC) to LVR (Low Voltage Return

Ground) on Machine for Short-Circuits. These 2 Machine Power Supply Circuits should Ohm-Out

to at Least a Few Hundred Ohms. If Close to Zero, you have a Short-Circuit Somewhere on Machine

or are reading a Short-Circuit back from a Bad Control Power Supply Board.

2 --- Second Common Cause is a Bad Power Supply #1 Board, Power Supply #2 Board,

Master-Monitor Board, or Slave-Monitor Board. Our Advise --- Send All 4 of these Boards,

Located in Slots S1, S2, S3, & S4 of Lower Cardcage, in to Machine Technologies,

and we will Test, Repair, and Update them to Current Specifications.

Note, Make SURE You Mark & Understand How to Get All Front & Rear Cables Connecting

4 Boards Back to Correct Positions, or you will Damage Boards at Power Turn-On!

Recheck All Cables Before You Power-On!

See 2 Photos Below For Cable Connection Help!

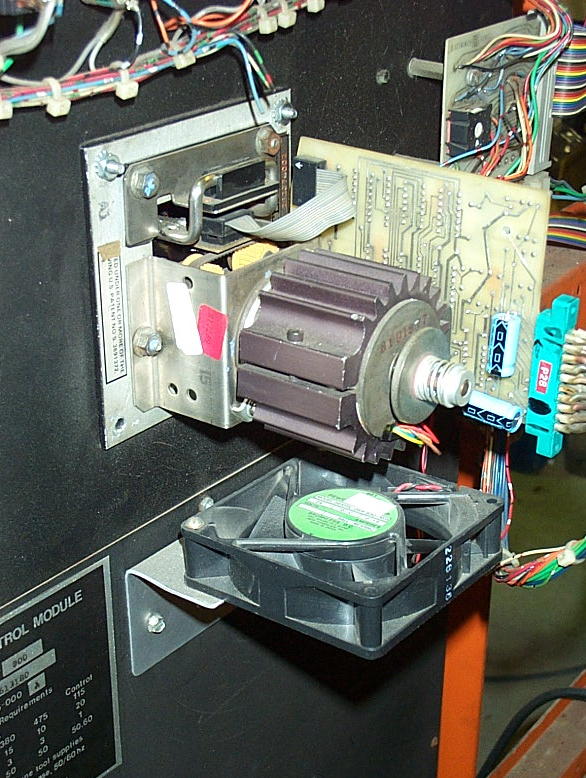

--- "SERVO DOWN" Message

Make Sure Servo Fan is Blowing Air Up

through Servo Boards or Servo will Trip-Out with a "Servo Down" Condition.

Look in Servo Drive Half of Control Cabinet. There are 3 Servo Drives (2 on FC750's), see if there is a Red-LED Light "ON" on one of the Servo Drives. A Red-LED Light is Located on

each PWMC Servo-Control Circuit Boards.

If so, you have a Over-Current Condition.

Turn-Off AC Power to Machine, then Disconnect the 2 Armature Wires going to that Axis's Servo Motor, and restart Control.

If LED does Not come on, Motor is probably Bad. We Stock Replacement Motors.

If LED still comes On, 1 or More of the 3 (or 2) Servo Boards are Bad. Send-In ALL 3

(2 for FC1000 T-Axis) Servo Boards for that

Axis, and we can Test & Repair Them.

--- TAPEREADERS

All HECC80 Controls came with a Decitek Model 262 Paper Tapereader for Part-Program Loading and to Run Control Trouble-Shooting Test Tapes.

Most, but not all, of these Controls have been Upgraded In-the-Field to allow Part-Program Data to be Downloaded from a P.C. Computer, which is much more convenient and reliable than Paper Tapes. There are 2 ways to do this Upgrading;

1 -- Upgrade CPU & 2 Prom Boards (HECC80/1 Controls), or Software-Upgrade (HECC80/30x Controls) to allow RS-232 Downloading directly from a P.C. Computer's Serial-Port to the CPU's

J1 Connector using a Special Cable.

Please see Our Web Page

2 -- Use a Tapereader Emulator. Tapereader's Cable to Control is Unplugged, then is Plugged into Special Connector Cable that goes directly into Emulator. Emulator Imitates old Tapereader and CNC Control Never knows the difference.

Both Methods have Advantages & Disadvantages. Machine Tech can help you decide and Install.

If you no longer use your Tapereader, then (with the Control Turned-Off) Un-Plug Cable from the Tapereader. Then Wrap a couple of turns of Electrical Tape around it (so No one will try to plug it back in) and tuck it out of the way into wiring-harness. Tapereader uses a Lot of D.C. Power and makes a Lot of Heat, even if not being used. By Unplugging it, you reduce Strain on

Power Supplies, put less Heat into Control, and help Preserve Tapereader for when you may

want it for Trouble-Shooting with Test Tapes.

Tapereaders get so Hot that you can Burn yourself just by touching Black Heatsink around Motor.

This is Normal! But this Heat eventually will Burn-Up Motor. Tapereaders are Expensive to Repair

or Replace. If you still use your Tapereader, then Mount a "Muffin" or "Boxer" Fan underneath it

with a L-Bracket, with Fan Blowing Upward over the Motor Heatsink.

This will Remove Excess Heat, and help Prevent Tapereader Failure from Motor Burning Out.

The "A" NC Control Series

HECC80/1 Control Common Problems & Fixes

--- "CHECKSUM ERROR" on Self-Scan Display as soon as you Turn-On Control.

Almost Always Caused by Failing Prom Boards. These Store the Executive-Run Program which

Runs your CNC Control. The ONLY Solution is to Send-In Prom #1 and Prom #2

(in Slots #3 & #4) Circuit Boards for Repairs and Updating to the Latest Software Revision.

Also, Send-In Front Panel Controller Board (Slot #7) for a Up-Date that aids Prom Boards.

On rare occasions, could be caused by a Bad Power Supply #1 Boards, or anything else

causing Intermittent or Bad Power from the Power Supplies.

Clean the Circuit Board Finger-Contacts with

Rubbing-Alcohol and Cotton Q-Tip Type Swabs Only!!!

Never,

Never,

Never,

Rub Circuit Board-Contacts with Anything Remotely

Abrasive! Or You Will Rub-Off the Very

Thin Gold-Coating and Permanently Ruin Circuit Board!!!

I have Updated this

"A" Control

at my Customer

H & W Metal in

Charlotte NC,

by removing the Original Remex Tapereader, and Retrofitting a TapeTwin Emulator Computer so that it can Read & Store Programs from Disks.

About 400 of these NC "A" Controls (and their Predecessors, the "30S3", "30S4", and "HC") were built from 1975 to 1979. There were other, older NC's built in the 1965 to 1975 Ere, but I will not cover them, as they All Should Be Scrapped by now.

The First FC1000/1 Machines, build in 1975 & 1976, had the First Version in this Control Series, the "30S3". About 30 of these Controls were build. They all had the Westamp Servo PWM Drives, which had a tendency to Burst into Flames, so Strippit was forced to come out with a "Conversion" Kit. To do Conversion, we Unbolted Servo Cabinet from the Control Cabinet, and bolted-on a New Servo Cabinet that used the General Electric Hi-Ack Servo Drives, which worked quite well.

Most of these early 30 FC1000 Machines had their Controls Converted, but not all.

30S3 Schematics are #400003-000. Addition Conversion Schematics are #400459-000.

The "30S4" Control was similar to 30S3, but it always came with Large G.E. Hi-Ack Servo Drives, and was used on larger FC1250/30 and FC1250/40 Machines only.

Built 1975 & 1976. Schematics #400060-000.

This "30S3 Conversion" and "30S4" Controls were Improved & Updated, then

became the "HC" Control (Houdaille Control). Also known as the "Compatibility" Control, as they were used on Both the FC1000 and FC1250 Machines.

These Controls were made in 1976 and 1977. Schematics #400200-000.

The "HC" Control was again Improved & Updated, and this became the "A" Control,

the Final Version in this NC Hardwired Control Series. Build 1977 to 1979.

Used #400269-000 Schematics.

Above NC Series of Controls were all "Hard-Wired", and were built with

Hundreds of I.C. Chips connected with Thousands of Blue "Wire-Wrap" Wires.

Controls had No CPU or Computer or Memory of Any Kind. These Controls Operated by reading the X, Y, and T information 1 Block at a Time from a Paper Tape, acting on this Information, then reading next block to Repeat this Cycle over & over again.

Fanuc Controls

At Left is the "General Numeric GN6 Control".

It Says General Numeric, but Every Part is Fanuc!

Control used Reliable Fanuc D.C. PWM Servo Drives which were built into Control Cabinet.

This was a very Popular CNC Control that was made through Early 1980's. It was a Good Control and Reliable, but was a Bit Intimidating to Operate, as it has Zillions of Knobs, Switches, Buttons, and Lights, so it Looked like Tokyo at Night!

Strippit started Phasing-Out their HECC80 Controls

in 1986 and Switched over to GN6 Controls on all FC1000/3 Machines, and later on, FC1250/30/1500 Machines and their other Big Machines.

Most of the Little Strippit Machines of this Era, like

FC630R & FC1000R, had Apple Mac & Windows P.C. Computer Controls that Strippit Hacked-Together. These are Now Nightmares as Many Parts are No Longer Available and LVD Strippit Won't Support them anymore. They have become So Bad, LVD Strippit Had to offer a Fanuc Retrofit for $80,000+

Beware & Avoid ALL Strippit's

Apple Mac & DOS & Windows P.C. Controls!

!!! YOU HAVE BEEN WARNED !!!

"R" Machines were Also Offered with Fanuc Controls

as Extra-Cost Option instead of "Mac" Control.

But Most Companies Went Cheap and did Not get

Fanuc Control Option, much to their Regret Now. FC630R & FC1000R with GN6 or OP Controls are

fairly Good Machines, but not many were built.

Di-Acro & Strippit also used GN6 on their Junk CAP1000 & CAP1250 & HPM1000 Machines they made, until late 1980's when Fanuc Discontinued GN6. Then Strippit made a few more CRAP1000 & CRAP1250 Machines with Fanuc OP-Controls, until Finally Discontinued these Machines around 1990

I will briefly talk about Fanuc CNC Controls as they are Now the World Leader in CNC Controls & Servo Drives. This is because G.E.'s "Neutron" Jack Welsh Capitulated, and "Nuked & Closed" All General Electrics's Control & Servo Drive Manufacturing Factories, Giving-Up Another Technology that was Invented in the USA,

and Allowing the Fanuc Co. to Win The CNC Control Wars.

Fanuc is now the Worlds Biggest Control Maker, and No One Else is Even Close

in Size and Scope. So, Like them or Not, They are Here. Thanks "Neutron Jack".

When Fanuc Originally Set-Up their American Division, they called it "General Numeric"

a Nice American Sounding Name. This was to Avoid Japanese Sounding "Fanuc"

Name and any Prejudices that may have come with it. There was Much Government Scrutiny in Early 1980's as Japanese were Busily Taking Over U.S. Machine Tool Industry. They have pretty well Completed this Mission now.

G.E. Partnered-Up with Japan's Fanuc Co.

(Mighty G.E. Becoming More like Fanuc's Lackey-American Marketing Arm, Than a Real Manufacturing Co.) and the

General Numeric Name Facade was Dropped.

They then became the "GE Fanuc" Co.

Next Generation of Fanuc Control was called the "O" (Zero), and Punch-Version was

called the "OP". It was basically just

a New & Improved GN6.

It had 7 "SoftKeys" under CRT Display

like the HECC80/30x Controls

Strippit had made Years Earlier

a Technology that made Control

Much Simpler to Operate & Use.

Control used A.C. Servo Drives, which are Improved Technology over older D.C. Drives.

These Controls were built through out the 1990's in several Versions and all are Good Reliable Controls. Recommended.

The OP's have now been Replaced with Next Generation of Fanuc Controls, which are called the "Oi". An Evolution of the older OP's, "i"s have some Nice features like

Built-in Disk Drives, and LCD-Displays instead of older CRT-Tube Displays.

They should be even better than the OP's, and are Recommended.

However, How Good the Control Works Depends on How Good of a Job Machine Manufacture Does Integrating Control Interface to Their Machine.

There are Many Complaints that LVD Strippit is Not Spending Enough Engineering Time on This Critical Interfacing, Which is Causing

Many User Operation & Maintenance & Troubleshooting Issues.

I Don't like the Fanuc Co.

They are Arrogant from their Large Market-Share. Control & Servo Repair Part Pricing

is Outrageous. Some Fanuc's A.C. Servo Motors are Priced at $10,000 to $25,000

with sometimes Months Delivery! What are You supposed to do with Your Production while Waiting Months? Older Fanuc Control & Servo Drive Parts are becoming "Unavailable". I think they are trying to Force You into Buying a New Machine with a New Fanuc Control on it! This is Certainly Not Very World Class.

Fanuc is Very Secretive and can be Difficult to Work-With.

I have NEVER met Anyone who has Even Seen Fanuc Control Electronic Schematics.

Having said all that, they have Won much of Worldwide CNC Control Business.

Fanuc makes Good Reliable Controls, are one of Biggest CNC Control Manufacturers

in the World, and have a World-Wide Support Network.

And So, Sadly, as there are now Damn Few Alternatives,

(Consider using Bosch & Siemens Controls, but are also Expensive & Secretive!)

I would be Hesitant to Buy Any New CNC Machine unless it Had a Fanuc Control.

--- Incorrect Heatsink

Some Chowder-Head at Strippit Designed the Floor-Plate, at Bottom of Control, with

2 Stud-Diodes Mounted on a Painted-Steel Heat-Sink that Does Not Dissipate Heat! Diodes get Hot enough to Burn-You if touched! This Heat Causes Diodes to Fail, and also Burns & Corrodes the

2 Wire Ring-Terminal Connections to Diodes. We Replace with a Larger Aluminum Heatsink, and Replace Old Wiring with with New Wires & Soldered-On Ring-Terminals.

This Work Requires New Parts and a Technician that Knows what he's doing!

Mount 2 Fans,

Blowing Upward,

under the Cardcage.

If you have them,

Check them Regularly

to make sure that they

are Working OK.

as they do

Wear-Out

and Stop!

Mount another Fan,

under the

Power-Supply

Lower-Cardcage.

Center the Fan,

Blowing Upward,

so that the Air-Flow

Blows Over the

2 Black Heatsinks

on the

Power Supply

#1 & #2

Circuit Boards.

McLean 6000 BTU Air Conditioner Mounted on Back of HECC80/1.

Also Note our Concept of a P.C. as a Local File-Server At The Control, with All P.C.'s Power-Plugs to

Power-Strip Inside Control.

Kooltronic 6000 BTU Air Conditioner Mounted on Side of "A" Control.

Also Note P.C.-Based

Tape-Reader Emulator,

Plug-In all P.C.'s Power-Plugs to

Power-Strip Inside Control.

Note! Air Conditioner's Draw a Lot of A.C. Power!

Older Strippit Machines had Only a 3KVA Step-Down Transformer,

to Provide 120 VAC, that Can Not Handle the Extra 15 Amp. Current Draw.

Wire These A.C. Units to an External Power Source.

If your Machine has the 5 KVA Transformer, it will handle the Extra Power,

But Run a Power-Cord all the Way back Directly to the Transformer itself!

!!! Note !!!

Many CNC Controls, like the G.E. 1050's, and Some of the Fanuc's,

Have Machine Parameters, MDI Data, and other Control & Machine Set-Up Data, Stored in Battery Backed-Up Memory.

If you Buy a Machine that has Been Stored for a Long Time,

Like in a Dealer's Warehouse, Without A.C. Power Being Connected to

Control, The Batteries will Run-Down, And All This Data Will Be Lost!!!

Your Control & Machine Will NOT Run Until ALL

Parameters & Set-Up Data Have Been Correctly Restored!

This Data is Sometime Very Hard, or Even Impossible to get from Original Machine Manufacturer. Make Sure you get ALL Original Set-Up Sheets, PaperTapes, or Data Disks, To be able to Reload This Data!!!

Get In Writing a Iron-Clad Guarantee that Machine will Run when you Buy it!

To Strippit's Credit, No HECC80 CNC Control has This Problem

as their Executive Run-Data is Stored in

Non-Volatile ROM-Chips or Bubble-Chips.

Note, The Failure Modes Here Are;

1 -- Stud-Diodes CR1 & CR2 Overheat & Fail, usually Causing a Short-Circuit and Blowing Fuse FU1.

2 -- About 50% of the Time, the Blown CR1 & CR2 will Also Cause The Diodes CR3 & CR4 to Fail.

3 -- The Blown CR3 & CR4 Diodes will then Cause the Power Supply #1 Board in Slot S4 to Fail.

We have a Repair-Kit Available that Replaces the Old Diodes & Heatsink & Wires with New Parts.

And if the Power Supply #1 is Bad, We Can Quickly Repair it in Only 1 to 2 Days Turn-Around Time.

Our Diode Repair Kit with

New CR1 & CR2 Stud-Diodes

Mounted with New Insulators on

New Aluminum Heatsink

with New Wires

& Ring-Terminals.

Also Includes

New Heavy-Duty

CR3 & CR4 Diodes.

The Strippit "Crappy" Apple-Mac

and IBM-P.C. CNC Controls

After Strippit Quit Designing & Building their HECC80 Controls, they bought and used Fanuc Controls for their Big 30-Ton Machines. But, I guess to try to lower costs, Strippit could Not Resist getting back into making Their Own CNC Controls again.

So in the late 1980's to 2000, Strippit made their Own CNC Controls again using P.C.'s,

which were used on their Cheaper Machines. First with the Apple Mac Computers,

and later on, a Second Type using IBM PC Computers, some running under

The Mac Controls were used on Many Versions of "R" (Rear Address) and 20-Ton Bridge-Frame FC1250 Machines, such as the FC1000R, FC1000XP, FC1250/20, Etc. While I tell people to Avoid these Machines, Don't Misunderstand me. They Were actually quite good Light-Duty Machines and Mac Controls worked quite well also.

The Problem is, these Mac Controls are now 30+ Years Old, and are NO longer Supportable! If your Mac goes Bad, you Can NOT go to Store and buy a New Mac

as it will NOT Work. You need to go to Flea-Markets & Ebay to try and find Exact Same 30+ Year Old Mac-Type (Like a Mac-Si) that YOUR Control was build with.

And of course, you are buying someone else's 30+ year old Worn-Out Junk Computer.

It gets Worse. Inside Control & Mac Computer, Strippit used several Circuit Boards

like Motion Control and P.A.C. Boards, that are NO Longer Available ANYWHERE!

Strippit will, for a Few Thousand Dollars, MAY Exchange These Boards.

So You Get Someone Else's Problem Trade-In Boards that Strippit took a stab

at repairing and will probably give You a New Set of Problems! I hear this quite Often.

I get Calls every week from Desperate people looking for these Boards or Repairs.

Sorry, I have None of these PC Control Boards and I do Not Repair these Boards.

As Strippit used Many Different versions of MAC's, and Servo Drives, and I/O Circuit Boards, and Software's, Etc., The Knowledge to Correctly even work on these

Controls is also being Lost as Time Marches On.

There was a Customer who called In Strippit several Times to Fix his FC1000R MAC

Control, but they could Not Repair it, and Customer Said Strippit just wanted him to

Buy a New Machine. So he Took Strippit's Advise and Bought a New Amada Machine.

After Mac Controls, which worked well when new, Strippit came out with IBM PC CNC Controls in Mid-1990's. These Controls were made in much smaller numbers,

were Not Documented Well, there is little to No Repair Expertise available, and

are Even Worse than MAC Controls!!! AVOID THEM ALL!!!

Again, Problem Here is LVD Strippit's Poor Repair Parts Availability and

Poor Support and Poor Service on ANY Machine or Control that is a few years old.

Strippit's Apple-MAC CNC Control

Strippit's IBM-P.C. CNC Control

Strippit's Apple MAC-Control on a Strippit FC1000R Machine

--- HECC80 Controls Hate Heat!

First generation Control Cabinets had just Door Exhaust Fans. Then Strippit tried Heat-Exchangers which were just Air-To-Air Radiators. Then they Finally quit being Cheap, and installed 6000 BTU Commercial Grade CNC Cabinet Air Conditioners. These Greatly Improved Reliability. If your Control has a Air Conditioner, make sure it Works! If your Control does not have one, take off Door Exhaust Fans, Seal-Up the Cabinet, Insulate Doors with 4' x 8' Foam-Sheets from a Building Supply Co., and install a Commercial CNC Cabinet Air Conditioner!

Do Not get Cheap, and install a Cheap Window A.C. Unit! They are Impossible to Mount Properly,

they Spray-Water into Control, and Do Not Circulate Air Properly Inside Control.

We can Drop-Ship Proper Air Conditioner Units for you to install. See A.C. Unit Photos Below.

Early HECC80's did Not have Fans Under Cardcage. If you do Not Have These Fans, Make a Bracket, and Mount 2 or 3 -- 4 Inch "Muffin" or "Boxer" Fans Under Cardcage Blowing Upward!

Also, Make another Bracket (We use 2 Pieces of Angle Aluminum) and Mount Another 4 Inch Fan Under the Power Supply #1 & Power Supply #2 Boards, Blowing Upward!

3 --- Other Possible Causes are;

--- Problems with Raw-DC Supplies on the Floor-Plate.

--- Problems with the Pre-Regulator Panel.

These Problems Probably Will Require a Experienced Serviceman to Troubleshoot & Repair.

General Electric CNC Controls

In the Late 1970's and Early 1980's, General Electric was growing rapidly,

and needed Turret Punch Machines for it's Manufacturing Plants.

G.E. Insisted that all CNC Machines that they Bought have G.E. Controls on them.

So over the Years, Strippit made a couple of Dozen "Special" FC1000/2 and FC1250 Machines with G.E. 1050 CNC Controls.

These G.E. Machines did not run as well

as HECC80 Control Strippit Machines,

as the 1050 was a Generic Control,

while the HECC80 was Custom Designed just for Strippit Machines.

Documentation and Support was also

Very Weak from Strippit for G.E. Machines.

These G.E. 1050 Controls, of Course, used the G.E. Model 2 Servo Drive System.

Here at Machine Technologies, we Stock All of the G.E. Model 2 & 3 Hi-Ack Servo Boards & Components.

See More At Our Servo Drive WebPage:

Most of these old G.E. Strippit Machines have now been Scrapped.

If you see one For-Sale, Don't Buy It!

In the early 1980's, Strippit also used another Version of the G.E. Model 1050 Control on their Model FC75/30 Turret Punch Machines. These also used

G.E. Model 2 Hi-Ack Servo Drive System for the X & Y Axis Motor Drives.

G.E. got in Bed with Fanuc, Closed all their U.S. Control Manufacturing Plants, so Support is Weak on these Old G.E. Controls. I would Not buy a Used CNC Machine that used an old G.E. Control.

Earlix Controls

In Mid 1980's to Early 1990's Strippit used a Japanese Earlix Control for their AG (Auto-Gageing) Single Station Punch Machines. They used

Earlix Model 2KH-700 Controls.

Earlix has Gone Out Of Business,

and there is No Parts & No Support available, so I would

Avoid These AG Machines!!!

One Failure Modes of Earlix Control was Switch Overlay on Top of Control. Elizabeth at Cobra Ind.

has Made New Switch Overlays Available for this Control,

Contact Her at Their Web Site;

If LED-Light is ON, on the Slave-Monitor Board, Most Common Causes are;

--- A Short-Circuit on 1 of Control Circuit Boards in the Upper Control Cardcage.

A Technician can Probe the 16 Test Points which will Point to the Board or Power Supply at Fault.

There is More Information in Control Schematics and Control Maintenance Manual on how to do this.

If you do Not Understand how to do this, you are Not Qualified, get a Experienced Serviceman!

A Bad Circuit Board can be Sent to Us at Machine Technologies Co. for Fast 48 Hour Repair Service!

--- Short-Circuit on Capacitors, Tapereader, Display, or Other Component on Control Front Door.

Fanuc

Oi-PC Control

on a

Strippit

Parma 1212

Machine

Fanuc

180i Control

on a

Strippit

Global 20

Machine