Un-Jam Your Strippit

Super 30/30, Custom 18/30,

Super 30/40-Mechanical, and

Sonic 18/30 Punch Press Machines!

From Time to Time, Machine Operators will Overload and Jam-Up the Strippit

Single-Station Punch Machine they are Operating. Usually by, Trying to Punch

Too-Thick of Sheet-Material, a Punch Too-Large for Sheet-Material, Wrong Die Clearance, Wrong Die, Wrong Punch, Dull Punch & Die, Crossed Punch & Die, etc.

Punch will be "Stuck-Down" with Machine Not finishing Punch-Stroke,

Punch is Stuck in Sheet-Material and Punch-Ram is Hard-Against Top of Punch.

And You Can Not Remove Sheet-Material, Punch, or the Swing-Arm Holder.

This is because you Now have OVER 30-Tons of Force Springing & Gapping

Machine C-Frame like the Large Spring that it is.

All of this Force is now directed through the Ram to Punch and Sheet-Material,

So, of course you can not get it out!

Now this is when your Rocket-Scientist Operator & Maintenance Guys

get-out their Big Hammers & Pipes & Pry-Bars & Acetylene Torches to try

to Pry-up the Ram, Rotate Flywheels, Cut Out Tool, to "Fix" the Jam.

Instead, they just Damage Machine & Swing-Arm Holder & Tooling.

If they Damage or Break the Swing-Arm Holder,

you are Out--Of--Business as they are NOT Manufactured anymore!

As an aside,

I would Build a Very Solid Stand Next to my Punch Machine with

2 Good Wood-Box Holder-Places for Both of my 1 1/4" & 3 1/2" Swing-Arm Holders.

Because lazy Operators usually just leave Swing-Arm Holder that they are not using

on Machine Table. Sooner or Later, will then accidentally Knock-it onto the Floor

and it will Break-In-Two Pieces that Can NOT be Repaired!

If Operator & Maintenance Guys Bothered to Read Machine Manual,

( You Do Have a Machine Manual, Right??? )

they would see they could-have

Simply Relieved the 30-Tons of Jammed Punch Pressure by;

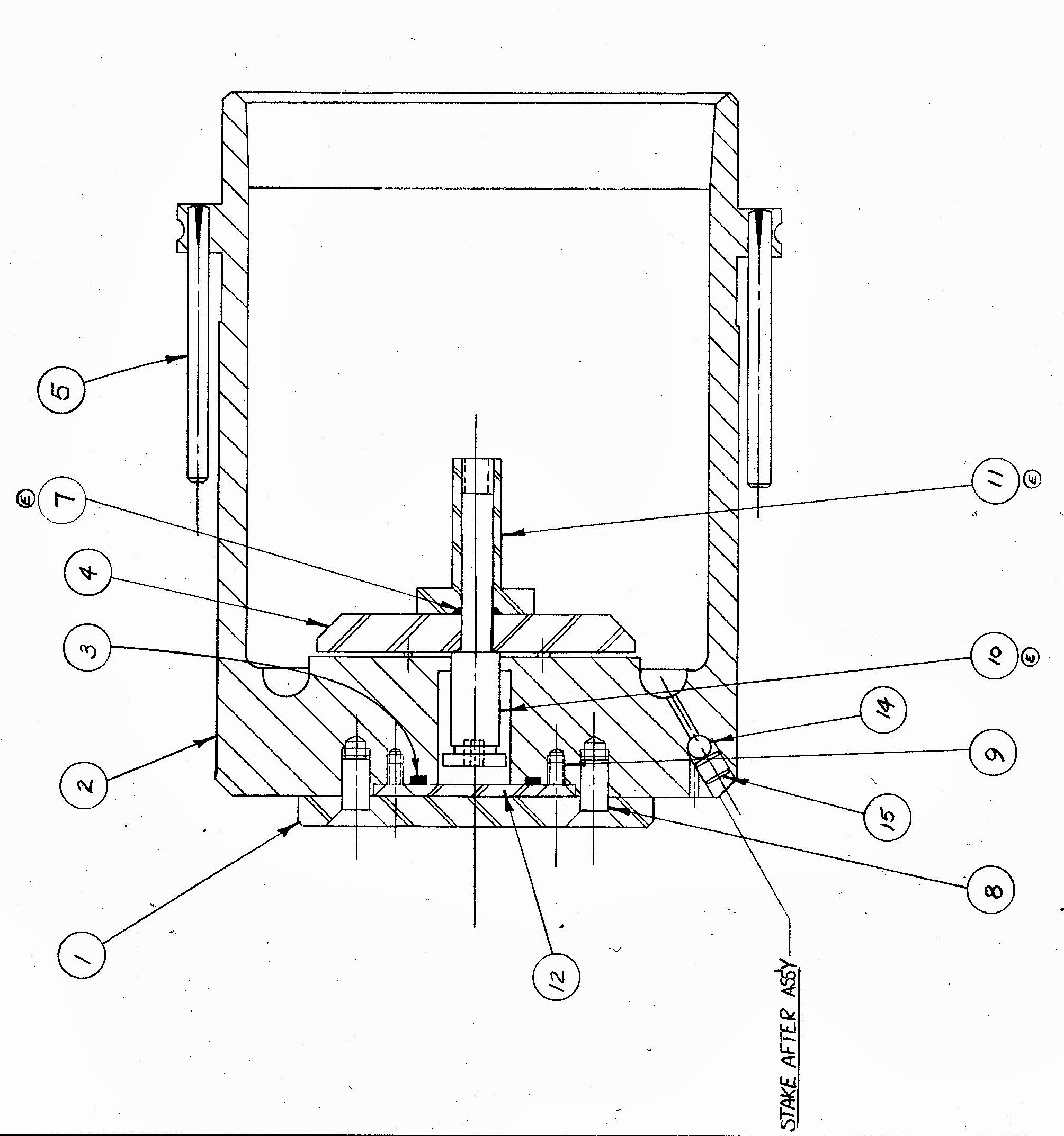

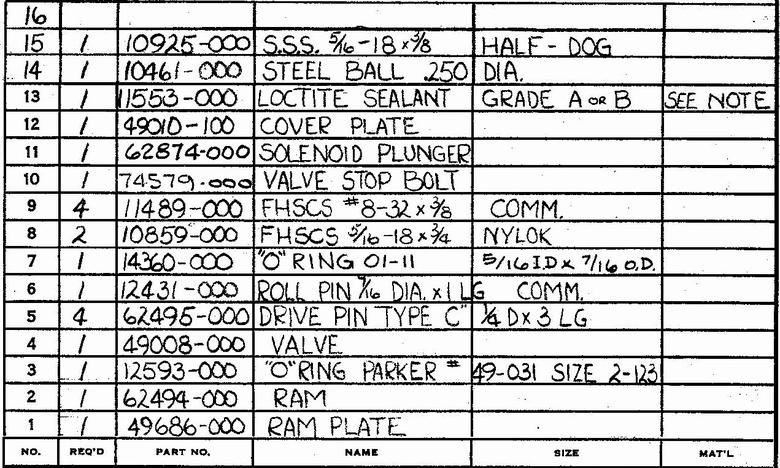

1 -- Taking a 5/32" Allen Wrench

2 -- Very Slowly Backing-Out 5/16"-18 Set-Screw, Item #15, usually

Located on Bottom Left-Side of Ram.

3 -- This Un-Seats the 1/4" Ball, Item #14, acting as a

Check-Valve to Ram Oil Chamber. See Ram Assembly Drawing Below!

4 -- This allows Trapped-Oil, Under Tremendous Pressure, Use Caution!,

in Punch-Ram to be Slowly Drained-Out,

and releasing the 30-Tons of Force from Jammed Sprung Machine-Frame.

Frame will Un-Load and Ram should Rise as Oil is Slowly Drained-Out.

5 -- You should now be able to Remove Swing-Arm & Tooling & Sheet-Material

6 -- Carefully Reinstall the Ball & Set-Screw, Don't Cross-Thread Screw!

7 -- Using #49579-000 Punch-Head Dip-Stick,

Refill Punch-Head at Bottom-Dead-Center with

any Good ISO-24 Weight Hydraulic Oil

or my New Favorite Mobil-1 Synthetic 0W-20 SAE Motor Oil

Do NOT Use a Heaver Grade Oil!

8 -- Now Correct the Original Problem that Caused Jam in the First-Place!!!

9 -- Also Check that 2 Drive-Belts were Not Shredded when Jam occurred,

Replace belts if necessary.

And, if Press Motor will Not Start, Motor Overload-Breaker in Electrical Box

on side of Machine probably has Tripped,

just Press-In Re-Set Plunger to Re-Set Breaker.

Try Not to Electrocute Yourself.

You should now be Back in the Punching Business! Be More Careful Next Time.

This Simple Pressure-Relief Valve is Built-In to All Strippit

Super 30/30, Custom 30/30, Custom 18/30, Sonic 18/30,

Pre-1977 Super 30/40-Mechanical and Custom 30/40-Mechanical Machines.

After 1977, Super 30/40-Hydraulic and Custom 30/40-Hydraulic Machines

were Redesigned to be Completely Hydraulic Punch Presses.

Very easy to tell them apart as

Mechanical Machines will have 2 Flywheels in Front of Machine, and

Newer Hydraulic Machines will NOT have any Flywheels at all.

This page was last updated: May 18, 2025

And Remember,

Don't Let Your Women Have Chewing Gum!

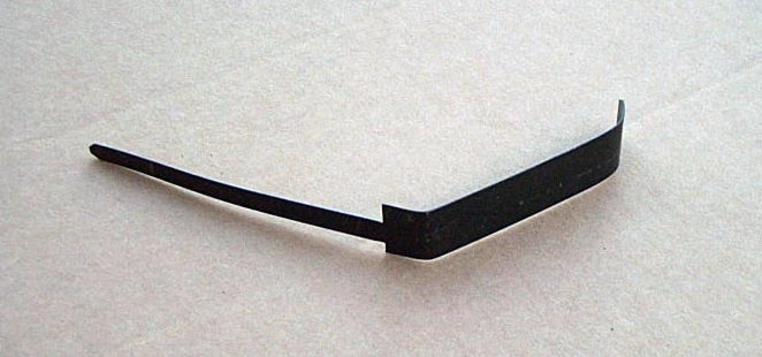

The Cut-Away View of the Above Ram can be Confusing as it is a

Side-View, Not the Front-View that would Face-You

with the Ram in your Machine.

Set-Screw of Relief-Valve is Actually on the Left-Side of Ram,

in the Area where the Notch or Cut-Out of Casting is

when the Ram is in Machine.

Sometimes it is Hard to find the Set-Screw Hole

as it is probably filled with a Half-Century of Grease and Dirt.

Also, Be Aware that this Assembly and Parts

Changed and Evolved somewhat

over the 4-Decades these Machines were Built!

You Actually do NOT have to Back-Out and Remove Set-Screw and Ball,

All the Way Out, to Release Oil Pressure.

As you Slowly Un-Screw Set-Screw,

The Ball will Move-Down with Set-Screw,

and Un-Cover a Small Drilled-Hole Passage-Way

where the Oil will Shoot Downward Releasing Pressure.

You can See Small Release-Hole in the

Above Ram Cut-Away View and in Photo Below.

Also, In our Punch-Head Rebuild Kits we have Changed from a

Cup-Type Set-Screw to a Extended-Tip Set-Screw

as we found on some Machines the Cup-Type Set-Screw

did Not Push Ball into it's Seat Tight Enough

so then it would slowly Leak Oil.

The Extended-Tip Set-Screw Fixes this Rare Problem.

Punch-Head Rebuild Kit

is Shown Below.

Set Oil to Correct-Level at

Bottom-Dead-Center with #49579-000 Dip-Stick!