Strippit

Super 30/40HD

Punch Machine Notes

Super 30/40-Mechanical Machines were made in 1960's & Early 1970's.

These Machines were basically just a

Super 30/30 with Bigger-Flywheels and Larger-Motor

and were Definitely NOT Good 40 Ton Machines!

Shops that insisted on Punching Large and High-Tonnage Holes with

Super 30/40-Mechanical & Super 30/30 Machines would, sooner or later,

Break the Piston and other Punch-Head Parts.

If you have a Super 30/40-Mechanical Machine,

I would NOT Punch Holes that Required over 25 Tons and I would

NOT Punch 1/4" and Thicker Material as Replacement Pistons are NOT Available.

So if you Break-it, you will need to Buy another Used Machine to Replace your Broken Machine that you can't repair, or else you will have to Run-Down to Home Depot

or Lowes and Buy a Hand-Drill to make your Holes. Your Choice.

Because of these Breakage Problems with Super 30/40-Mechanical Machines,

Strippit Replaced it with the Super 30/40-Hydraulic Machine in 1976.

These were Excellent Heavy-Duty Machines

that would Punch 40-Ton Holes all day long with No Problems.

Strippit Stupidly Quit making these Excellent Machines about 1990,

and

LVD-Strippit STUPIDLY No longer makes Any Single-Station Machines.

Strippit Super 30/40HD

Painted in the 1970's Puke-Green

As stated previously, these were Excellent Machines.

But, of Course, there are some trouble areas now that they are getting old.

1 --- Machines are now about 30 to 45 years old.

Do You Do ANY Maintenance???

Did you EVER Change the Hydraulic Oil??? Yeah, I didn't think so.

So the Hydraulic Oil in your Machine is now at least 35+ Years old.

But, yet You wouldn't Dream of Not Changing the oil Regularity

in your Pick-Up Truck or your Wife's Caddy for Decades. Go Figure.....

That Old Oil has Dirt & Water & Metal Particles in it that has Been Wearing-out

your Expensive Hydraulic-Pump, Hydraulic-Valve, Punch-Cylinder, Seals, etc.

Hydraulic Tank holds 55 Gallons of Mobil DTE-24 Hydraulic Oil.

Change The Fucking Oil!

2 --- Strippit really Screwed-Up here. They put a Course Screen-Filter that will

Stop Cock-Roaches & Floating Mice going up the Suction-Tube Pick-Up in

Oil Tank that goes to Pump. But it will NOT Stop & Filter-Out Dirt & Metal

Particles in the oil that will Damage All Components in Punch System.

Common Good-Practice in Designing Any Hydraulic Systems is to put a

Spin-On Filter in Return-Line from the Hydraulic-Valve.

Hydraulic Systems, like on this

Super 30/40-Hydraulic Machine, have the Pump Running and Maintaining

Oil Pressure to the Punch-Valve All the Time when Machine is Turned-On.

If not actually Punching at that Moment in time,

Valve just Dumps the oil through a Return-line Back-to the Tank.

A Low-Pressure Filter should be Inserted into that return Line!

But Strippit Did NOT put a Return-Line Filter on this Machine!

95-Percent of the time, Machine is Not actually Punching, so the oil is constantly

being sent back to Tank. If you were to Add a Filter to the Low-Pressure

By-Pass Line coming out of Valve, your Oil would be

Constantly Filtered Clean Preventing Many System Wear-Out Problems.

Pictures of Typical Small Filter-Mount & Filters are Shown Below,

but I would use a Much Larger Filter to handle output from

this 10HP Motor & Pump Combination which Flows About 19 GMP.

or

or equivalent.

If I owned 1 of these Machines, I would Plumb-in a Filter Assembly!

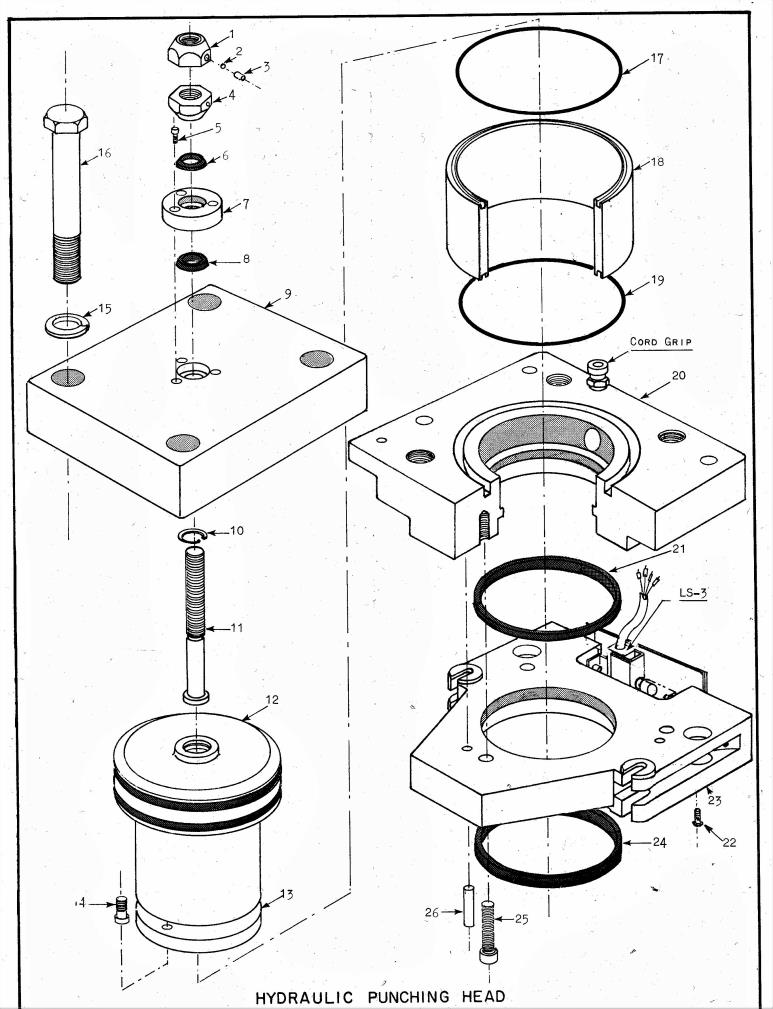

Strippit Super 30/40-Hydraulic Machine Punch-Head Seal Kit

--- #17317-000 Item #24 BOTTOM PISTON-WIPER IN BASE-ASSEMBLY

--- #17318-000 Item #21 BOTTOM PISTON-SEAL IN CYLINDER

--- #17319-000 PISTON WIPER-SEAL, 2-USED

--- #17320-000 Items #17 & #19 CYLINDER-END O-RINGS

--- #17321-000 Item #8 ROD-SEAL

--- #17322-000 Item #6 ROD-WIPER

--- #17323-000 Item #10 2 INVERTED RETAINING RINGS, SO YOU HAVE A SPARE!

--- #15901-nyl Item #3 2 IMPROVED NYLON-TIP SET SCREW,

WHICH TAKES THE PLACE OF

Item #3 #15901-000 STANDARD SET SCREW

and Item #2 #48286-000 NYLON-BALL

I now have Small Stock of Kits of these Special Seals!

See Above Photos.

If you have "Lost" your Operation & Maintenance Manual

Buy a New Manual Before Starting on this Head-Rebuild!

I still have a few Manuals left For-Sale at this time,

and

I also Included information on the Hydraulic Components.

Strippit Super 30/40HD

Painted in the 1980's Yellow with Racing-Stripes

When Visiting Our Farm,

Please

Do Not Piss-Off Our Animals!

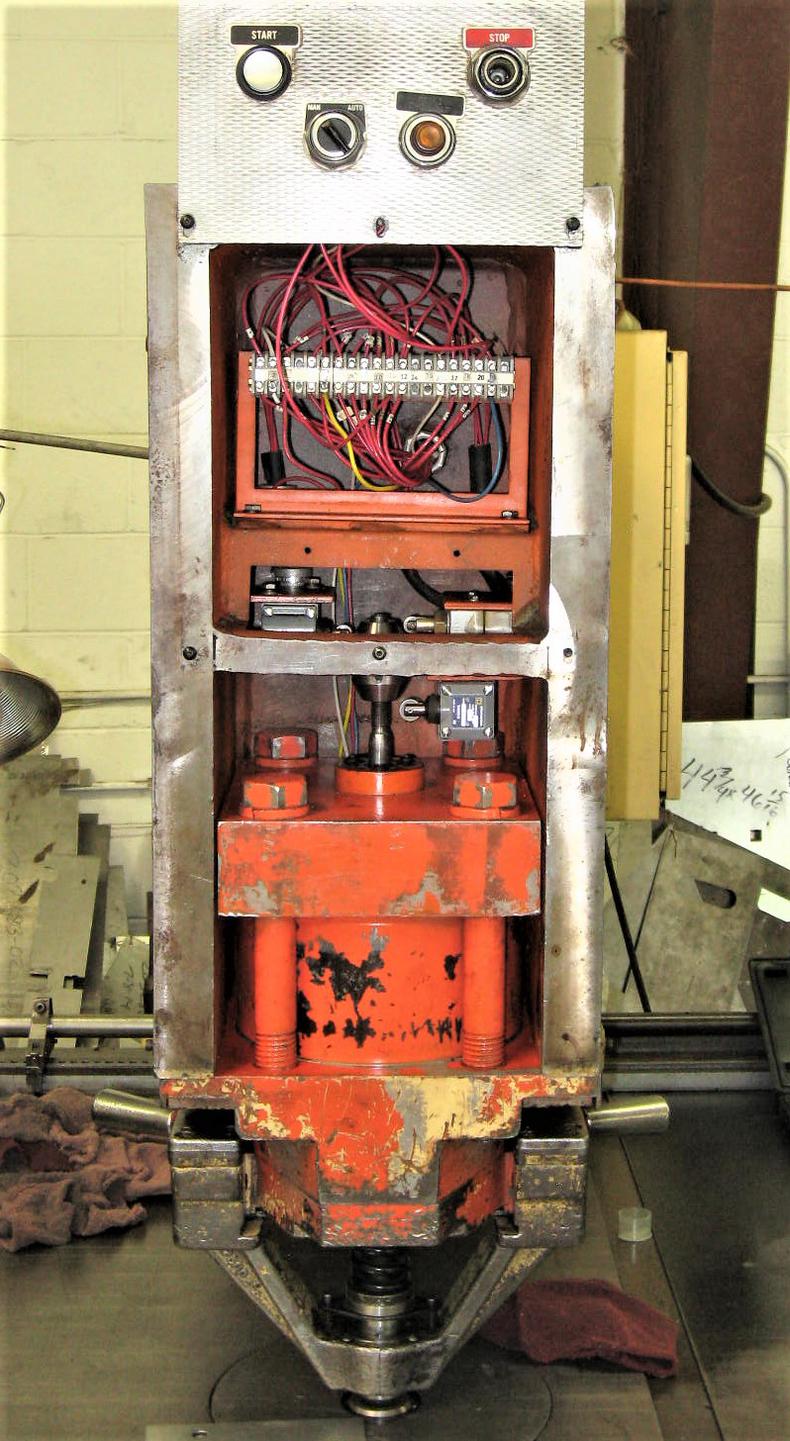

3 --- Back-In-The-Day in 1975 when Strippit's Engineers built the 1st

Super 30/40-Hydraulic Machine, Engineer's put the 2 Hydraulic Hoses to

Punch-Cylinder on Outside of the Frame where they would be Easy to get to.

Then Strippit's Marketing-Pukes looked at it and said

"Move & Hide The Hoses because they weren't Pretty!" True-Story.

Remember Strippit's Marketing-Pukes when you Try to Un-Screw or Replace Hoses.

So Hoses were moved inside the frame where they are impossible to get to!

Every time you Punch with these Machines, the Hoses Jump & Flex, Inside the Frame,

from Punching Pressure Cycling on & off. After many years of this,

Hoses can Wear & Blow-Out, and are Extremely Difficult to Access and Replace.

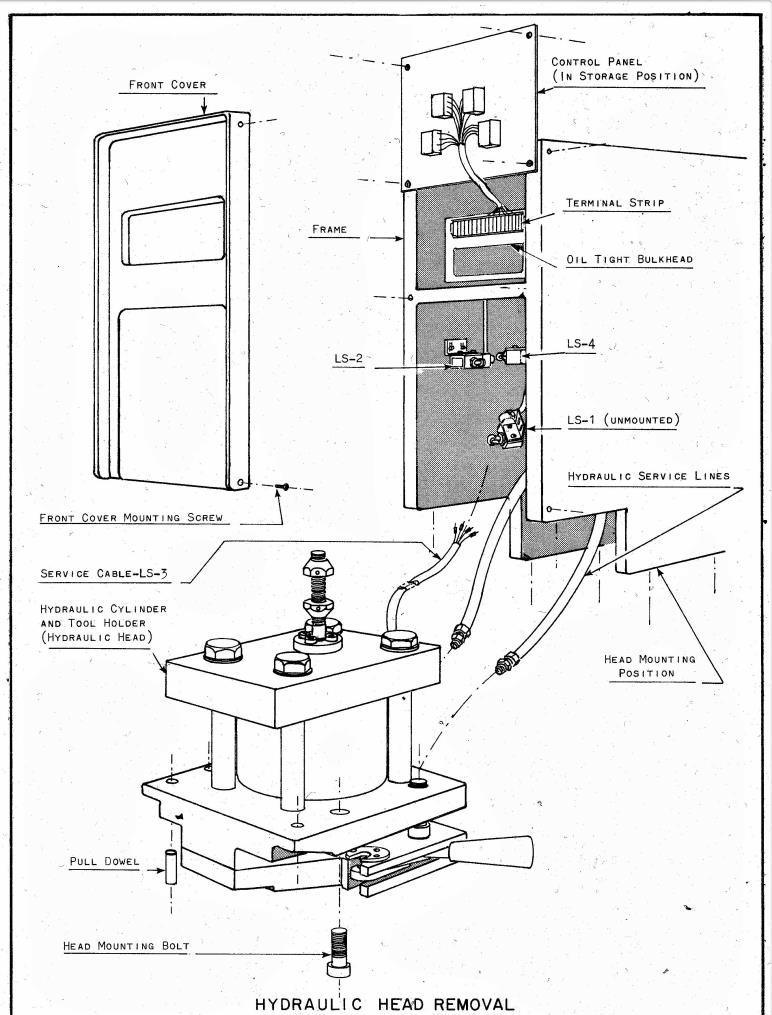

You will have to drop-down the Heavy Punch-Head to get access to hoses,

another Very Difficult Operation.

If you are replacing them, Take Old Hoses to a Good Hydraulic Supply House like

and make New Hoses out of Premium 4000PSI or 5000PSI Components,

do NOT use the Cheaper 2000 or 3000PSI Stuff!

T-SAF 30

Later-On, in the Early 1980's, somebody in Strippit's Marketing Dept.

had a Wet-Dream in the Shower, and came-up with the Idea of

Bolting a Tool-Turret on the Side of their Excellent 30/40HD Single-Station Machine.

So Strippit Did. A 12-Station Tool Turret Was just

Bolted-on to the Left-Side of the Frame, and a Very Clunky Indexing Mechanism

would advance the Turret Very Slowly & Very Imprecisely 1 Station at a time.

This New Machine was called the T-SAF 30.

These Crappy Machines had Many Problems, so Avoid Them!

4 --- As All these Machines are now Decades old, Cylinder Seals tend to become Brittle with Age after 20 years or so, Wear-Out, then Crack & Break into pieces causing

Punch-Cylinder to leak lots of Oil at the bottom of the Punch-Ram.

Cylinder-Bore may need to be Honed-Smooth if it's Scored from Dirt & Contaminants because you Didn't Change Oil regularly or add a By-Pass Filter.

Unfortunately, it's a Big-Job to Replace Seals.

Alan Suda, in the Mid-West may do this work if he's in The-Mood & has Time,

and Tom Penrod, on the West Coast can also do this work.

Both are listed on my Independent Strippit Machine Service Webpage

Otherwise, you will Need to do this yourself.

Depending on how far you need to go on Taking this apart, Getting Repair Parts, CleaningUp or Possibly Honing the Cylinder Bore, Etc., Budget a few days to do it!

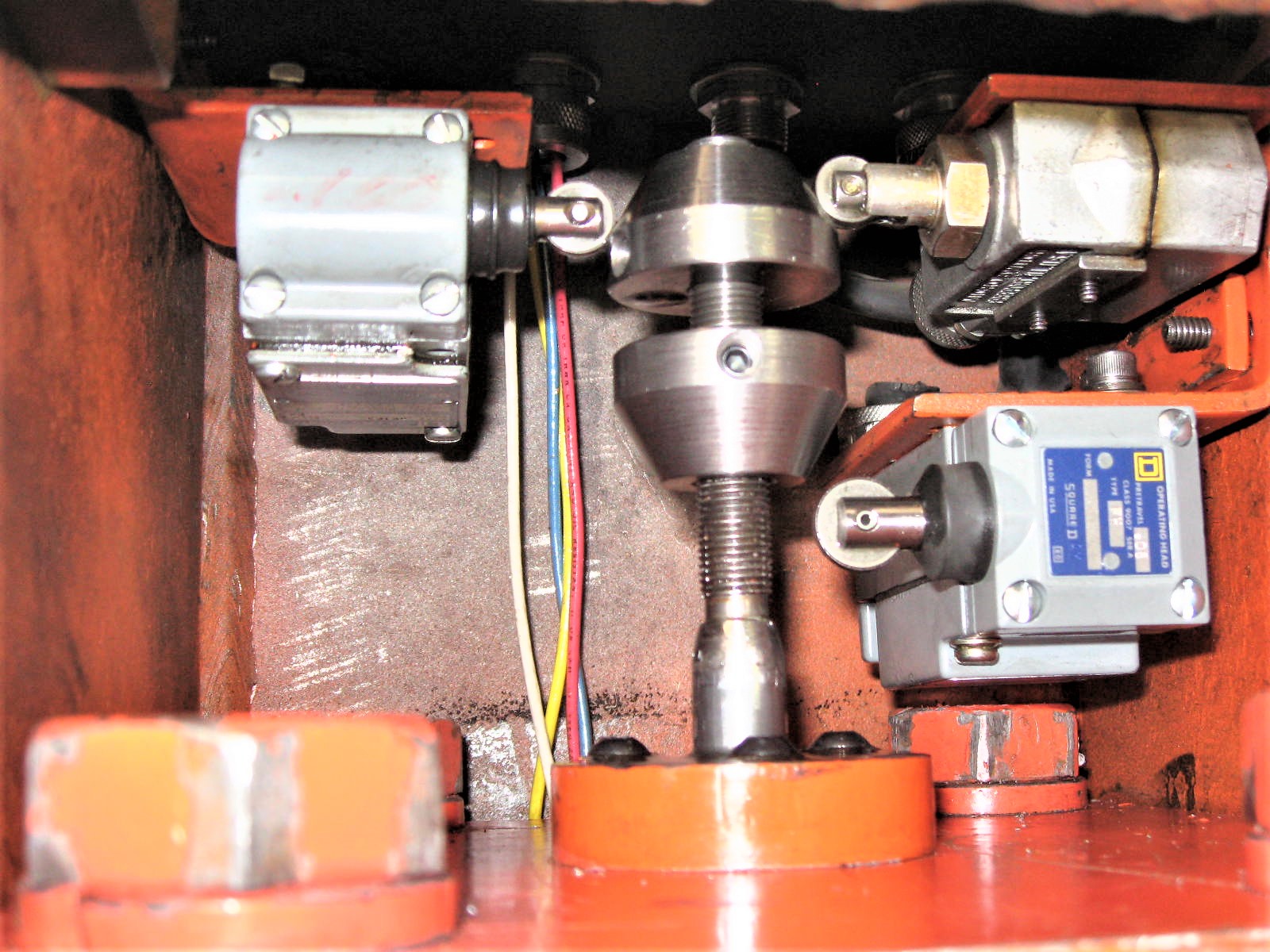

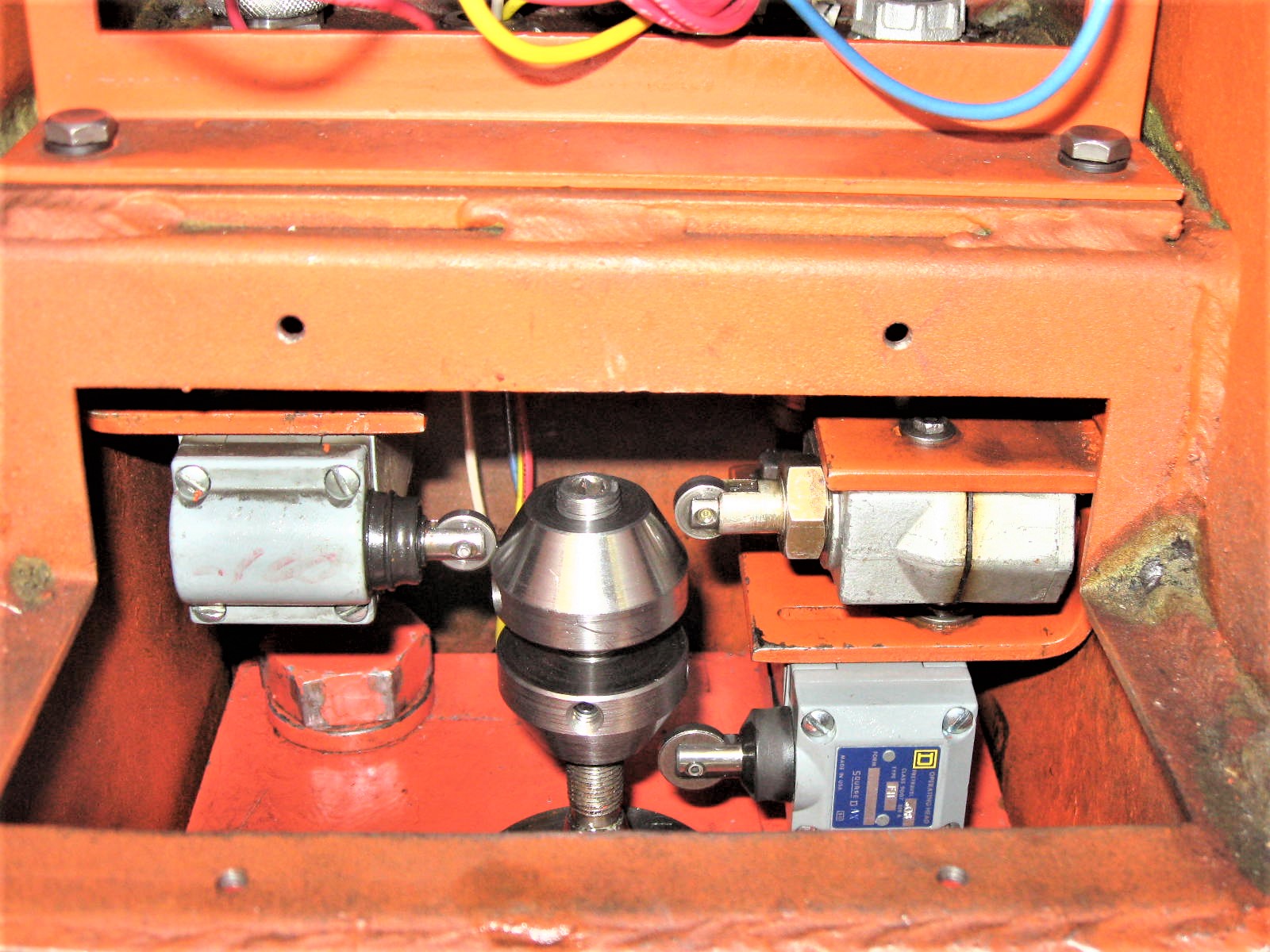

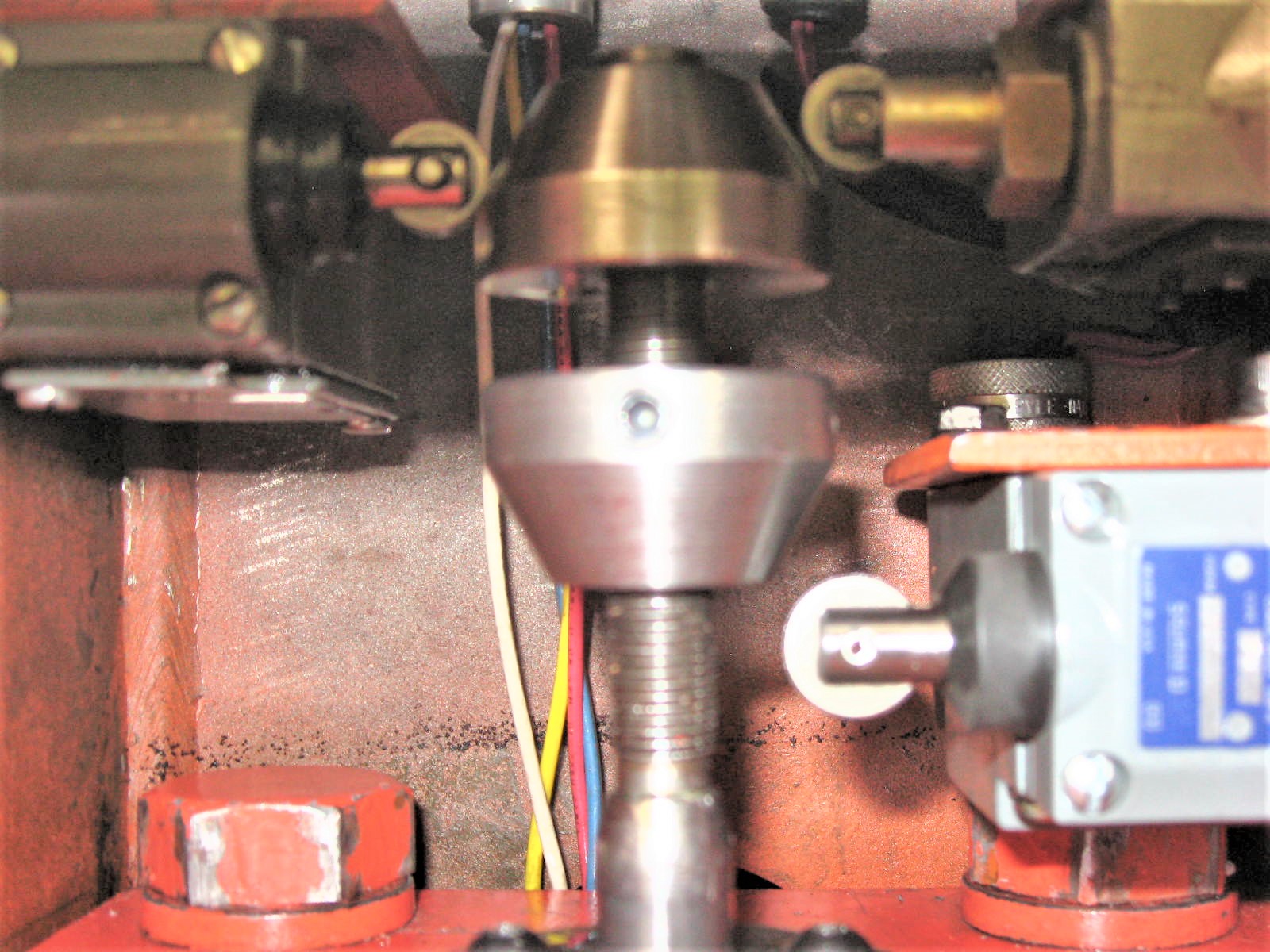

Before You Start, Take Photos of Everything, Especially Switches & Cams,

to insure you get it all back together Correctly!

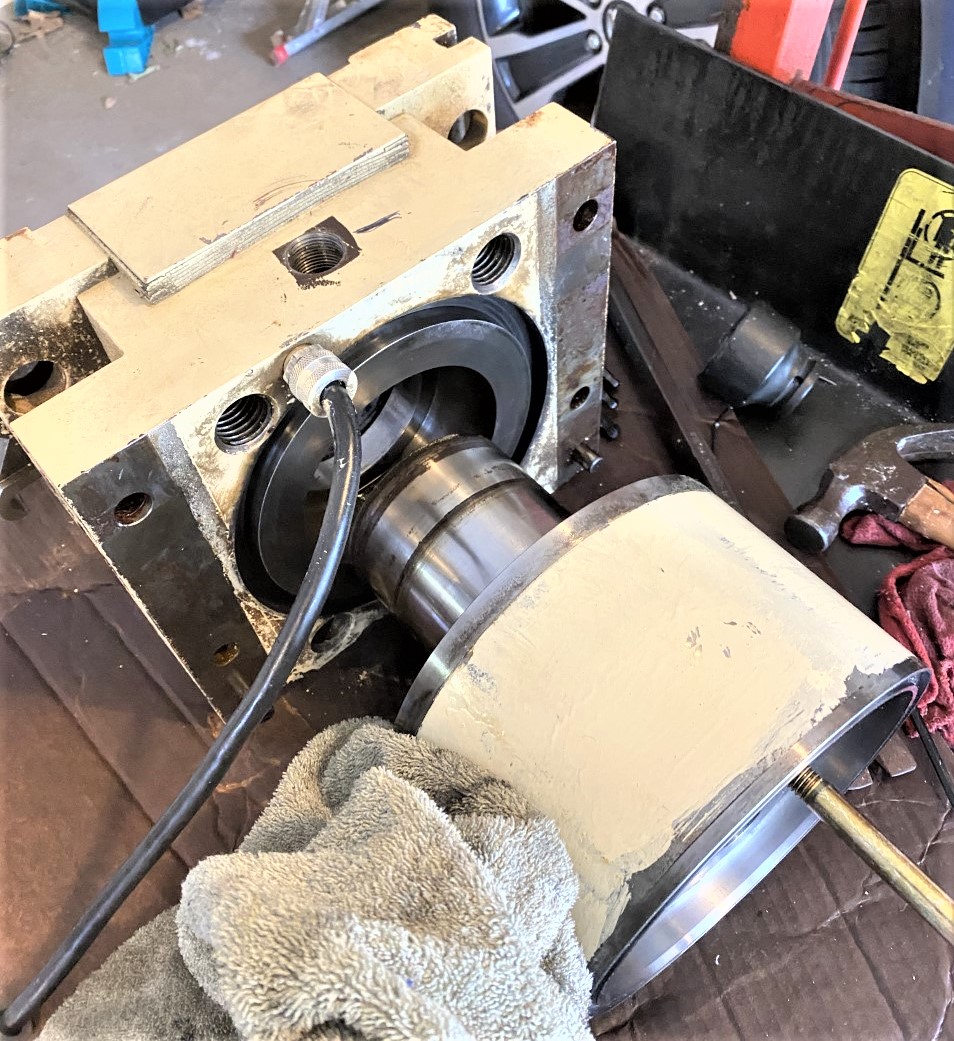

Drop-Down Cylinder Assembly onto the Machine Table, take-off Hydraulic Hoses,

take-off Tool-Holder Base-Assembly and Cylinder Rod-End.

Some Shops will Pull the Cylinder out and send it, with a New Set of Seals,

to a Hydraulic Repair Shop to be rebuilt.

Be Very Careful, as the Big Oily Punch-Cylinder Weights a 1/4 Ton! Don't Drop-It!

1 of my More Clever Customers Says He rebuilt his Punch Cylinder in only 1 Day!

He maneuvered his Fork-Lift Forks under Punch-Head to Lift it Down & Move it.

A Problem of rebuilding Cylinder is Holding it while Loosening & Re-Torquing

the 4 Big Tie-Rod Bolts, as they are Torqued to 850 Foot-Pounds!

He put a Wood 2 by 4 (2 by 6's might be Better) in his Press-Brake Lower-Bed,

laid Cylinder on 2 by 4, then put another 2 by 4 on Top, then Carefully Bumped-Down

Upper Press-Brake Ram until Cylinder was Secured in the Brake like a Giant Vise!

Again, Be Very Careful, as the Cylinder Assembly Weights a 1/4 Ton!

When Done Rebuilding Cylinder, you will Need a

to achieve the Required 850 Foot-pounds of Torque on the 4 Tie-Rod Bolts!

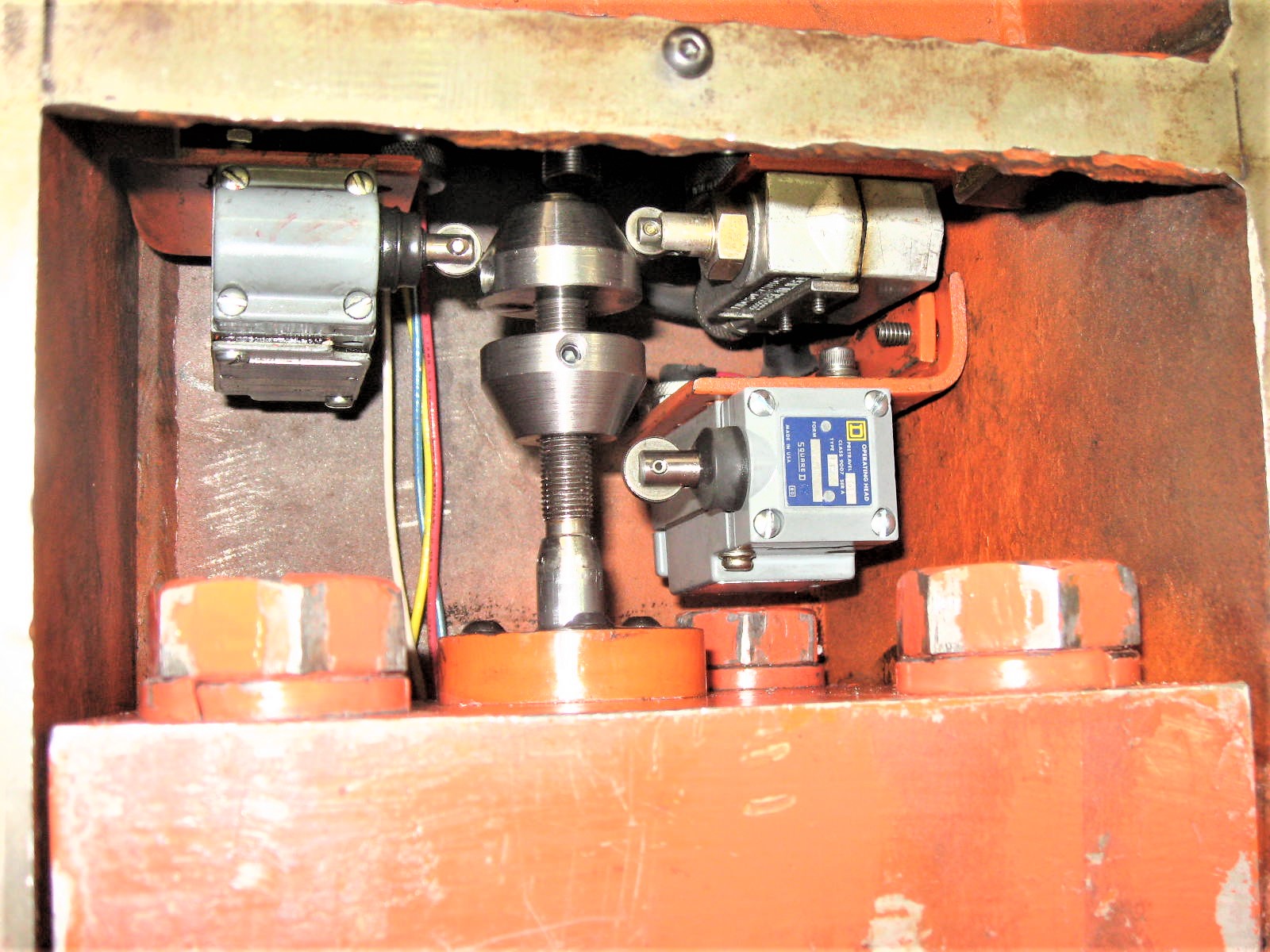

5 --- Try to Not Damage Switches as they are NOT made anymore!

Take Very Good Photos of Limit Switches & their Set-Up Before you take them all off!

If you are completely Disassembling the Cylinder, the #11 Switch Actuator Rod is

held-on to Piston only by a Item #10 Retaining Clip. I had a Machine where the Clip

Popped-Off of the Piston so Switch-Rod became Loose.

Customer then had to Completely remove Switches, Pull Cylinder,

sent it to a Rebuild Shop, and then reinstall everything back in Machine.

Then Switch Actuator Rod Popped-Off, Again!

Customer had to Completely remove Switches, Pull Cylinder,

send it to the Rebuild Shop, Again.

It took a Month and Many Thousands of Dollars to get this Machine Finally Repaired, All over a 50-Cent Retaining Clip!!!

It should be OK, but check the Clip Groove on Piston to see if it is Buggered Up!

Re-Machine if somehow damaged.

And Always fit a NEW Inverted Retaining Ring (Snap-Ring) in Piston-Groove.

Special Inverted Retaining Ring is used because a Standard Retaining Ring (Snap Ring)

Lug-Holes stick-out too far and would hit the #11 Switch Actuator Rod.

2 of these Special Rings are Included in our Seal Kit!

5 --- There are No Electronics in a Super 30/40HD Machine.

Just the Punch-Head Limit Switches and Several Relays.

Strippit Engineering was Confused by some New U.L.-Insurance Requirements

in the Late 1970's when this Machine was designed,

and so, The

Relay Logic is Much More Complicated than necessary,

and can be very difficult to follow.

I replace Stock Relays with Special LED-Light Type Relays

which Light-Up when the Relay is Pulled-In,

making it Much Easier to Follow & Trouble-Shoot Problems.

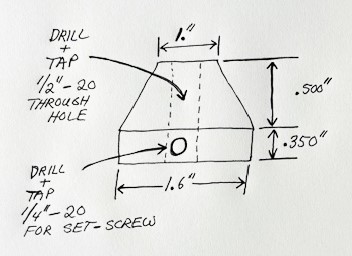

6 --- For Un-Know Reasons, Strippit Stupidly made the Cams, See Above Photo,

that go on Switch Actuator Cam-Rod out of 6-Sided Hex-Bar-Stock on a CNC Lathe.

Problem #1 is, the Pointed Tapered-Parts of Cam Actuates Switches OK,

But Rod is NOT fixed, so it Continually Rotates over time, and

the 6 Flat-Sides of Cams Do NOT always Actuate the Switches!

Problem #2 is, Your Operator, The Rocket-Scientist, Learns that he can Reach-In

and Rotate Cam-Rod a Bit, so it Will Actuate Switches, using Pliers or Vice-Grips

or Small Pipe-Wrench. Now the Cam-Rod is Scratched and Scarred and Ruined!

Problem #3 is, The Scratched and Scarred Cam-Rod Tears-Up the Rod-Seal

which now Blows-Out 3000 PSI Hydraulic Oil out the Top of Punch-Cylinder!

To Fix, you now have to Remove Switches, Pull-Out the 1/4 Ton Punching-Head

and Punch-Cylinder, Remove Hydraulic Hoses (Replace if Worn!), Tear-Apart

Punch-Cylinder, Rebuild Punch-Cylinder with New Seals, and Have a

Good Machine Shop make a New Cam-Rod with Nice Smooth Sides,

and Put it All back together again. A Shit-Ton of Work!

Tell Your Operator, The Rocket-Scientist Not to Do This!

And if he Does it Again, Slap-Him-Silly & Make Him Fix It!

My solution was to have a Machine Shop make me New Cams with NO Flat-Sides!

See Sketch Below of New Cams I had Machine Shop make, and

Look Closely at these New Cams I had made in Photos Below.

This page was last updated: May 19, 2025

FC75/30

As if the T-SAF 30 wasn't Bad Enough,

Strippit Marketing had Another Wet-Dream in The Shower

and told Engineering Dept. to take the T-SAF 30 Machine

and to just Bolt-on a CNC Control to make it a

Baby CNC Turret Punching Machine!

So a General Electric 1050 CNC Control & Servo-Drives were

Bolted-On to the Right-Side of the Frame.

This new Machine was called the FC75/30.

They somehow thought it would go over Big in Europe, but it never did.

But they did sell a lot of them in the U.S. Because they were Cheap.

These Machines are Automated Crap and should be Avoided!

As the T-SAF 30 and FC75/30 were Built off the Super 30/40HD Machine

The Punching-Head & Cylinder & Seals & Switches are all the Same

and use the Same Repair Parts and Repair Notes Provided Above.

Always use a

NEW

Inverted Retaining Ring!

There is Not much Clearance inside Piston

so use a Good Pair of

to get Ring in & out!

2 of these Special Rings

are Included

in our Seal Kit!

This Webpage is Still Under Construction

and I will Add to it, from Time to Time,

when I Feel like it.....

Strippit used a 1/4"-20 x 1/4" Long Set-Screw to Lock-Position of Cams on Cam-Rod, with a Nylon-Ball in front of Set-Screw, to Protect Threads on Rod.

But,

I use a 1/4"-20 x 3/8" Long Brass-Tipped Set-Screw

I buy from McMaster-Carr #91381A535

See Nice New Cam-Rod Above,

More on Cam-Rod in Section #6 Below.