Strippit

Super 30/30 & Super 30/30AG (Auto Gage)

Custom 18/30 & Custom 18/30AG (Auto Gage) Punch Machines with

MAG-Switches

In 1960, Strippit started building Super 30/30, Custom 18/30, and

Super 30/40-Mechanical Punch Machines. These New Model Machines

were built using Mechanical Limit Switches for Punch-Stroke Timing.

Strippit used Switches from Allen-Bradly, General Electric, Microswitch,

and others. Some switch Brands worked better than others.

These Machines are very sensitive to Proper Switch Operation and will have various Punching Problems if Switches are not working correctly.

2 Decades later, in 1981, Strippit changed to Magnetically-Operated

MAG-Switches on these Punch Machines as it was thought they worked better.

And In some ways they did work better. But they did not have Unlimited life

of True Electronic Switches and Eventually they will Wear-Out & Fail,

just like the Older Type Mechanical Switches.

Note that MAG-Switches are made in 2 Very Different Polarities,

LS1 Normally-Open MAG-Switch on Left Flywheel is Part # 19274-000.

LS2 Normally-Closed MAG-Switch on Right Flywheel is Part # 19275-000.

There are also several Generations of MAG-Switches with

some small differences between them.

The 1st Type was "Blue" MAG-Switches, named because of Blue-Color Cases.

The LS1 Switch is on Left Flywheel and is Always Normally-Open Type.

The LS2 Switch is on Right Flywheel and is Always Normally-Closed Type.

We No Longer use the Blue MAG-Switches and

have Replaced them with Newer Versions of MAG-Switches

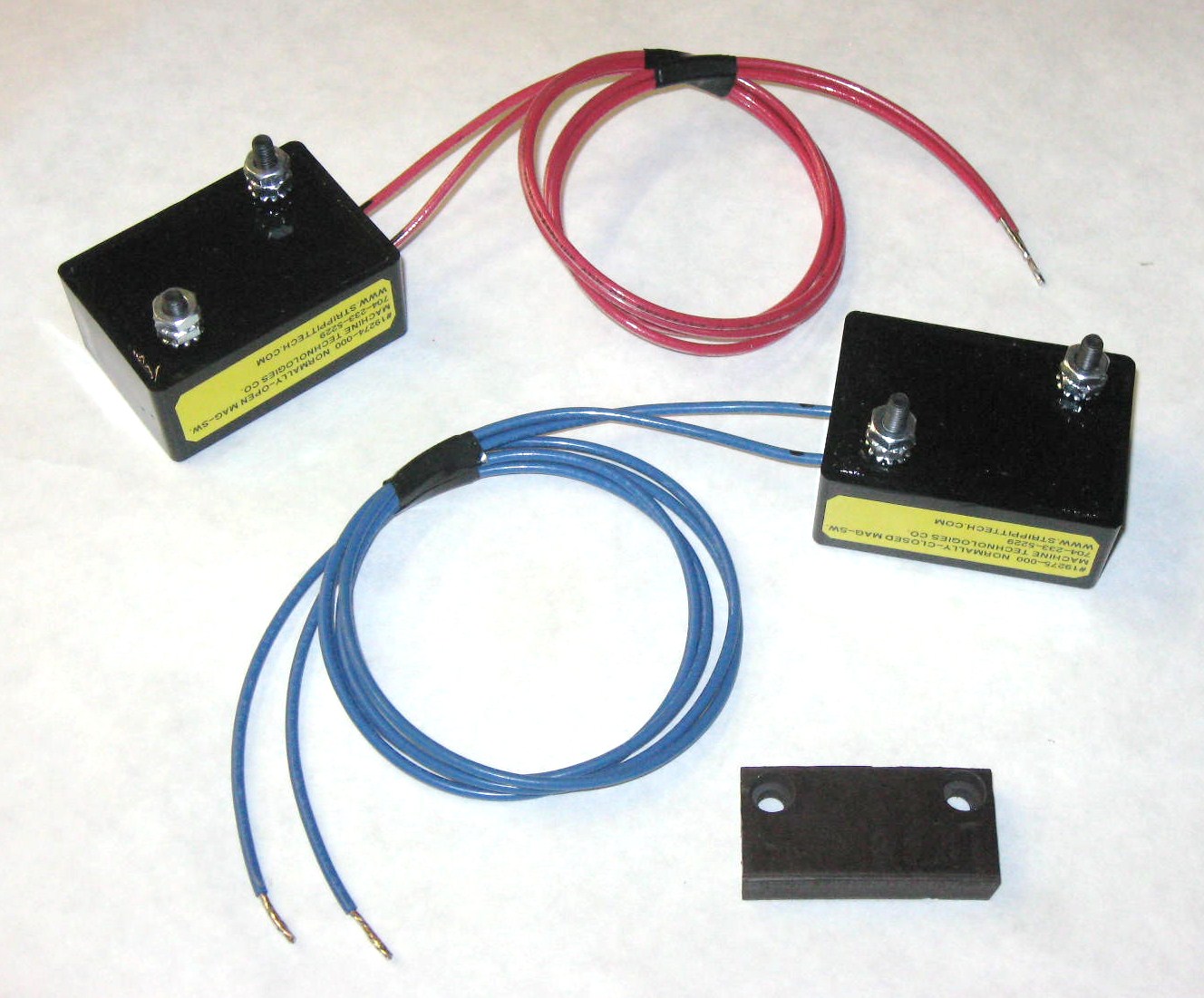

2nd Type was made with

Square-Corner Black Boxes.

LS1 for Left Flywheel

had Red-Wires.

LS2 for Right Flywheel

had Blue-Wires.

Both also had

I.D. Stickers on Both Sides to Positively Identify Switch Type.

We also did-away with Awkward Metal Conduit Fittings on Switch Box.

Now Simply Route 2 Wires to Terminal Strip in Overhead Electrical Box.

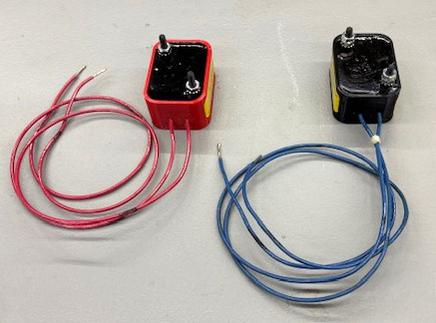

3rd Type was made with

Round-Corner Red & Black Boxes.

LS1 on Left Flywheel

had Red-Box.

LS2 on Right Flywheel

had Black-Box.

Both had I.D. Stickers on Both Sides

to Positively Identify Switch type.

Both 2nd Type and 3rd Type Switches

worked very well, But did have a Problem.

The 2 10-32 Switch Mounting Screws

were Designed-in to the

Wrong Opposite Corners and

would not fit the Bracket.

This could be Easily Solved in 2 ways;

--- You could Drill 2 New 3/16" Mounting

Holes on your Switch Brackets

OR

--- We can provide New Switch Brackets

with Mounting-Slots on Opposite Sides

As 2nd Type and 3rd Type MAG-Switches are no longer made,

this is No longer a Problem.

Replacement Switch Brackets,

we Provide,

for 2nd Type and 3rd Type MAG-Switches

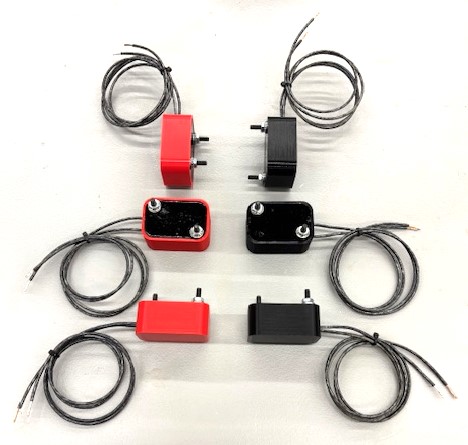

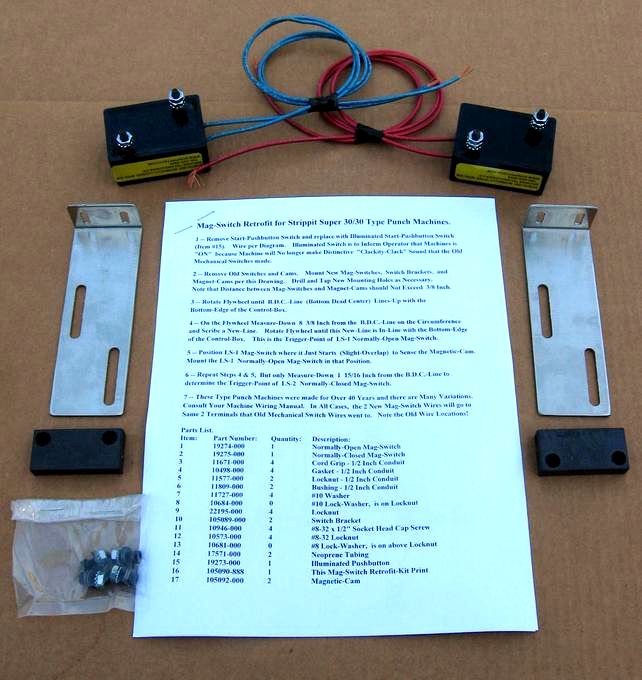

This is Our Current and 4th Type

Mag-Switch that is still in Production and we have In-Stock.

The 2 10-32 Screw Locations

have been Moved to Match the Original MAG-Switches and

these Switches will

Fit Old Switch Brackets Perfectly

RED-Box LS1

Normally-Open MAG-Switch

goes on Left Flywheel and is

Part # 19274-000

BLACK-Box LS2

Normally-Closed MAG-Switch

goes on Right Flywheel and is Part # 19275-000

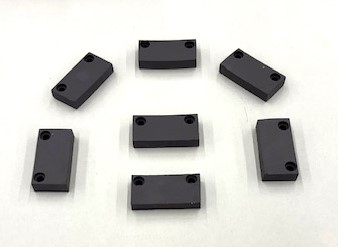

MAG-Switches are Activated

by these Specially Machined Magnets Bolted to the

inside of each Flywheel.

Magnets are reliable, But can

be Broken if Mounting Bolts

get Loose or if a MAC-Switch gets Loose and Hits it.

We still have a Small Stock of these Magnets For-Sale.

Testing of MAG-Switches

MAG-Switches are Magnetically Activated Electronic Switches

that Can NOT be Checked or Tested with a Ohmmeter or Multimeter.

They can Only be Tested, with a Current Limiting Load, with 120 Volt A.C. Power.

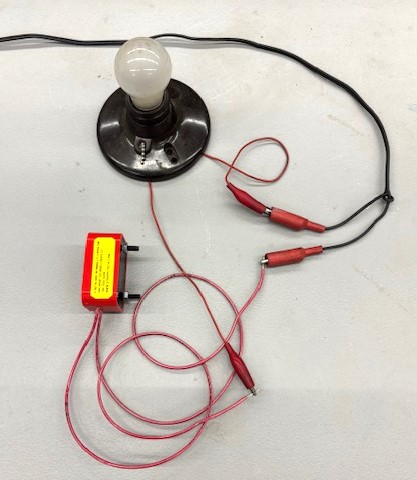

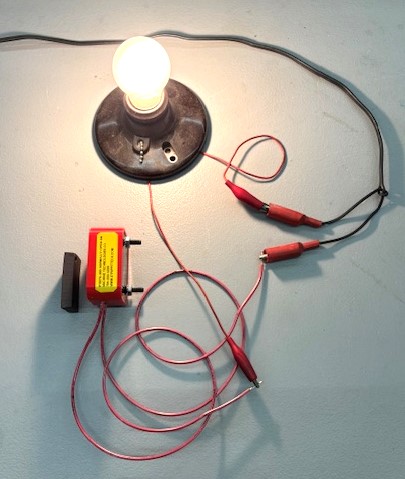

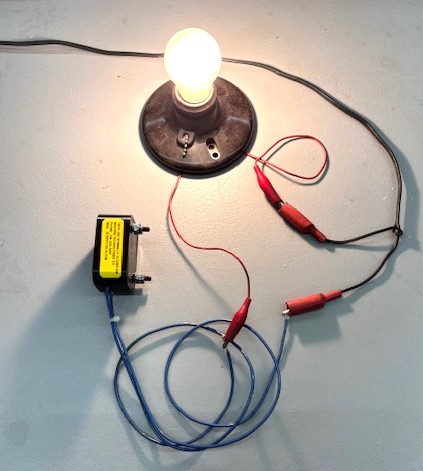

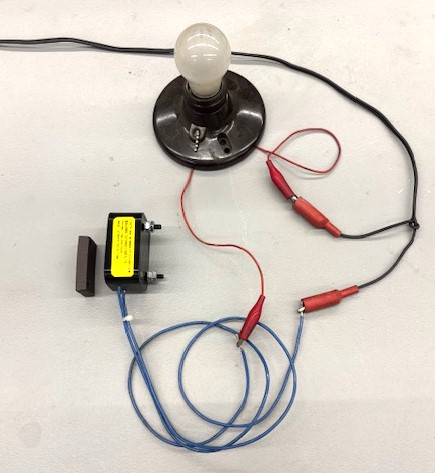

In the next 4 Photos we will Demonstrate how these 2 Types of MAG-Switches work, With and Without, Magnet Activation. I'm using what we called, back in my

OIT / DeVry Electronics School Days, a Suicide-Cord which is a simple

A.C. Power Cord with Alligator Clips on the Ends for easy Temporary Connections.

! CAUTION ! Do NOT Test this Way Unless You Know what you are doing,

as it is Easy to get Shocked or Killed!

As You will be Dead a Very Long Time, there is No Reason to Rush it.....

I'm using an Old 40 Watt Incandescent Light Bulb for a Load.

Do Not use a Higher Wattage Bulb as they have a

Large Current Surge when Cold that maybe could Damage Switch.

If you are Good with Electricity, you could also remove Wires or Fuses

to Press-Drive Motor so that Flywheels do Not Turn with Machine Turned-On.

Then you could Rotate Flywheel by Hand and see LS1 Pull-In CR1, and

see LS2 Drop-Out CR1 when Magnets go by. Could also measure 120 Volt A.C. Power Turning ON & Off, with a Voltmeter, from Switches as Magnet goes by.

Do NOT let CR1 be ON more that a Couple Seconds

as you might Burn-Out Solenoid in Piston!

LS1 ON LEFT FLYWHEEL

NORMALLY-OPEN MAG-SWITCH

IS OFF WITH NO-MAGNET

LS1 ON LEFT FLYWHEEL

NORMALLY-OPEN MAG-SWITCH

IS ON WITH MAGNET

LS2 ON RIGHT FLYWHEEL

NORMALLY-CLOSED MAG-SWITCH

IS ON WITH NO-MAGNET

LS2 ON RIGHT FLYWHEEL

NORMALLY-CLOSED MAG-SWITCH

IS OFF WITH MAGNET

In the 1980's, many Single-Station Machines had their

Mechanical Switches Removed, and then had

#105090-000 MAG-Switch Retrofit Kit Installed

Believing that it would improve Reliability.

As I don't believe it is any more Reliable than Mechanical Switches

and it is somewhat Difficult to Install, I have Stopped Selling this Retrofit Kit.

However, if you own a Machine that uses MAG-Switches,

you should Consider Buying a MAG-Switch Spare-Part Repair-Kit

as I don't know how much longer I am going to have MAG-Switch In-Stock.

Note!

Machines with MAG-Switches don't make the Clackity Noise

from Mechanical Switch-Arms Hitting the Cams as Flywheels Rotate.

So, Strippit Replaced the simple "On-Switch" with a

Green-Lighted Push-Button On-Switch so that,

at a Glance, you could tell if the Machine was On or Off.

Spare Parts

As I will Probably Retire Soon, You should Consider Stocking Spare Repair Parts, because these Special Repair Parts are NOT Available anywhere Else.

LS1 Normally-Open

MAG-Switch, Red-Box

#19274-000

LS2 Normally-Closed

MAG-Switch, Black-Box

#19275-000

Switch Magnet

#105092-000

CR1 Retrofit Relay Kit

#49787-000

CR2 Plug-In Relay

#12125-000

LS3 Double-Punch Prevent Switch #12979-000

Punch-Head Solenoid

#49011-200

Punch-Head Rebuild Kit

#119951-000

After 5-Decades of Firefighting Service

My Cousin Edward

Takes His Last Call