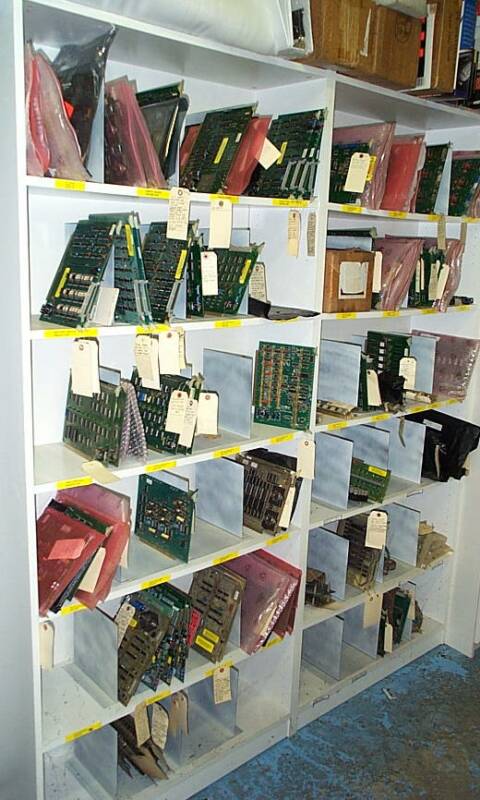

Special Strippit HECC80 CNC Control Parts

Machine Technologies Stocks Strippit HECC80 Control Repair Parts

that Other's (New Machine Salesmen Perhaps?) Claim are "Not Available". While Not

state-of-the-art, older Strippit CNC Machines are usually Already in Place & Running,

are Affordable, Parts & Service Are Available, and Can Do "The Job" in most cases.

If you need features like Auto-Index Stations,

Programmable-Rams for Forming, Etc., by all means, Go Ahead and Buy a New Machine!

But Don't Spend $300,000.00 to $450,000.00 on a New Machine Just because

"Someone" told you "Parts & Service are not available", because Its Just Not True!

This is the Burroughs Self-Scan Display

that was Originally used on Strippit Houdaille HECC80, HECC80/1, HECC80/102, HECC80/28,

HECC80/750, and HECC80/752 CNC Controls.

Burroughs Displays have

Characters that are Bright-Orange in Color.

These are out of production, but we have a small

stock of these Displays left.

We can also Repair Customer's Displays if

the Problem is caused by Bad Electronics.

If Display-Tube is Bad they are Not Repairable.

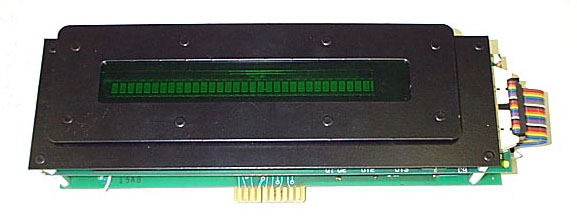

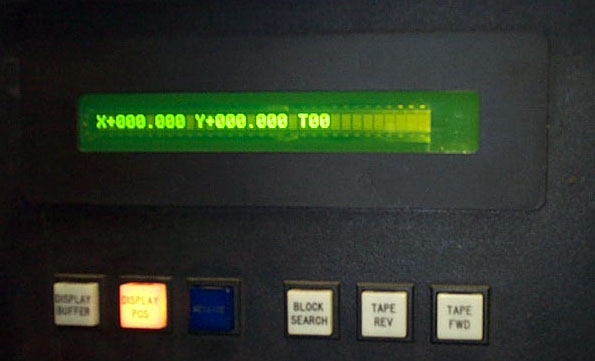

Below are 2 views of #401605-000 Display Retrofit Kit that takes the place of old Burroughs Display. This Display Type is easy to identify as it's Characters are a Green-Blue Color.

Later HECC80 Controls listed above left Strippit Factory with this type Display. Other Controls had

new Display Retrofitted when original Burroughs Display went bad. If you have a bad Burroughs

Display on your Control this Retrofit Display Kit is the Fix. We Stock Retrofit Display Kits!

Retrofit Display Kit is not quite a bolt-in replacement as several wire changes need to be made.

A good Service Technician should be able to install it in about an hour. Retrofit Display is More Reliable than Burroughs Display, but if you have one go bad, we can Repair it in 2 days or less.

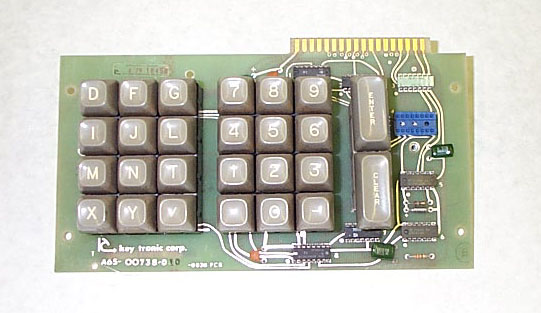

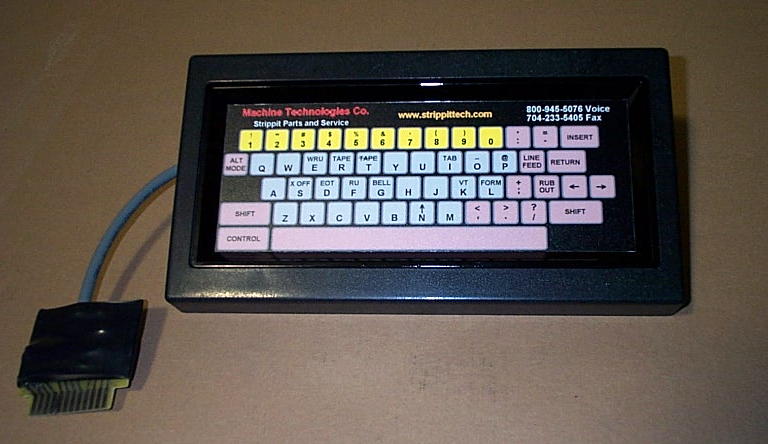

This is original #22359-000 Custom-Made MicroSwitch

Keyboard as used on Strippit Houdaille HECC80/3,

HECC80/302, HECC80/304, HECC80/306, and

HECC80/BC Controls. As Cheap Imports

(Thanks Free-Trade Policies!) have driven most American Keyboard Companies Out Of Business,

This Keyboard Is No Longer Made! We have a stock

of Original Keyboards & Repair Parts and can Repair some Keyboards, depending on particular failure.

The HECC80/30x Controls listed above

will Not Run with out a Good Keyboard!

To Solve this Problem, Machine Technologies Manufactures a Custom Keyboard that bolts easily in

to these Controls. Just remove old keyboard, drill 2 small mounting holes, bolt-on New Keyboard, and plug-in data cable. Does NOT require a Service-Call, and takes about 10 minutes to install. This New Keyboard Retrofit also has advantage of being Sealed, so Dirt & Grit from Plasma and LaserTool Machines will Not Wear it out, a Problem Original type Keyboard did have.

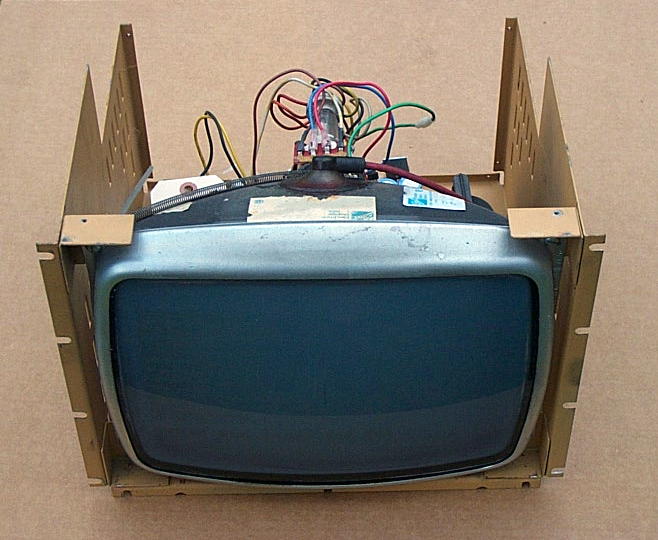

There were several types of CRT--Monitor Displays

used in HECC-80/30x Controls. We can repair some of them and stock Replacement CRT Monitor Display Units for those that we can not fix.

Call us for details on CRT Display Repairs.

We also Stock Control Panel Switches, like

"Cycle Start" Switch. And All Circuit Boards,

Power Supplies and other Electronic Control Parts.

Call Us on what You are Looking for!

This is the

#400799-600 Keypad

as was used on All

HECC80/1 Type Controls.

We Still have a stock of New & Rebuilt

Keypads left.

We also have all the

Parts to REPAIR Your Keypad Quickly!

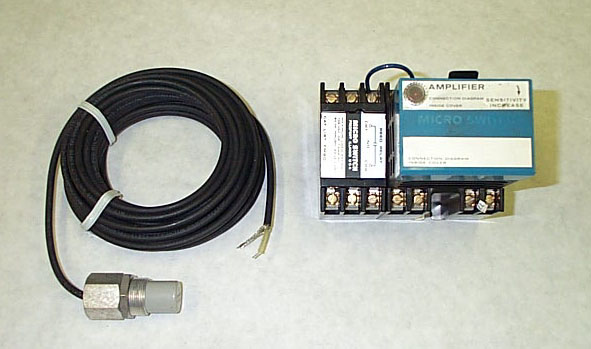

This is the Original Microswitch

#17623-000 Strip-Sensor &

#17624-000 Strip-Amplifier (Blue-Box) &

#17609-000 Strip-Relay Assembly

Parts were used on most all NC & CNC

Strippit Machines built from 1975 to 1987 for Punch-Tool Strip-Detection .

If your Machine will Not Contour-Nibble,

your Strip-Circuit is Not Working!

Sensors are No Longer Available

as they were Discontinued in 1994.

We have Amplifier & Relays In-Stock.

ALL of These Parts have been Replaced

by Our #17623-500 Strip-Sensor

Retrofit Kit Shown Below.

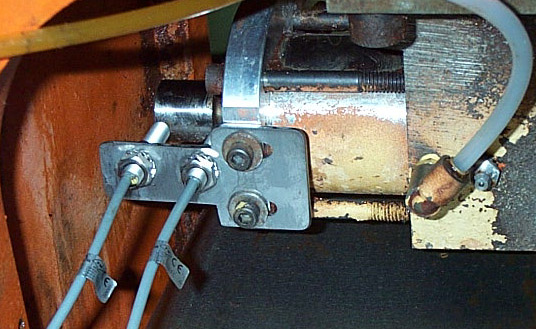

This is #17623-300 Strip-Sensor Retrofit Kit

that Replaces All the Old Strip-Sensor &

Blue-Box Amplifier & Relay Assembly.

Part #17623-300 Installation is Not Hard, and Instructions are Included. Old Sensor and Blue-Box Assembly are Removed, New Strip-Sensor Installed, and then connect Sensor's 2 Wires. Kit is for All Strippit Houdaille built Controls from early NC "A" Types to All CNC HECC80 Types.

-----------------------------------------------------------------------------

This Kit was Not made for Fanuc Control CAP-1000

and CAP-1250 Machines which also used Old Strip

Amplifier Assembly. However, It Will Work on CAP

Machines if a Small Relay is Wired-In to Invert

Strip-Signal to the Fanuc Control. Strippit's Service Dept. Now uses Our Sensor and their #8312088-000 Relay on CAP Machines for CAP Strip Circuits.

We Stock a Relay Kit with Instillation Instructions,

that is used with #17623-300 Sensor Kit

that will Work on CAP1000 & CAP1250 Machines.

This is the #401350-000 Bubble Memory Board

that All HECC80/30x Controls use.

These Controls use this Board as a Solid-State Disk-Drive to Store All System Programs that Run Machine and Control, as well as also Storing User-Part Programs.

Bubble Board is in Cardcage Slot #6.

If your Machine has a Strippit Houdaille HECC80 Control

and a CRT Monitor Display, It is one of the HEC80/30x

Controls. The 5 HECC80/30x Control Types Are;

--- HECC80/3 1st Version of this Class of Controls,

NO-Bubble Memory. Used on about the first 30

FC1000/3 Machines, Most were Later Retrofitted in the

Field with Bubble-Memory to the HECC80/302 Type.

--- HECC80/302 Used on FC1000/3 Machines,

has Bubble-Memory

--- HECC80/304 Used on FC1500/45 Machines

--- HECC80/306 Used on FC1250/30/1500 and

FC1250/30/1500 Lasertool Machines

--- HECC80/BC Used on Blanking Center Machines

We have Bubble Memory Boards & Socket-Type

Intel Bubble Chips In-Stock! Machine Technologies can

usually Repair Failed Bubble Boards and Reload System

Software. However, there are Many Different Software

Versions. If you have a good set of System Software

Paper-Tapes, take Good Care of them as they are

useful in Repairing these Boards.

We have Updates & Fixes for Both Bubble Boards and

the Machine itself to help Prevent Various "DFxx" Dead Bubble Board Error Messages. Call for Details.

This is #17546-000 Resolver Feedback Package,

and the #17648-000 Resolver-Coupling.

Both are Located on End Of Each (X, Y, T) Servo Motor for Axis Position-Feedback to CNC Control.

When a Machine Axis is

"Jumping", "Mispositioning", or "Running-Away",

The Resolver Is The First Place to Investigate !!!

Remove Package from Motor, then Spin and Rock the Small Resolver Shaft between your Fingers.

If there is much Shaft-Sideplay, or if it Turns-Rough, Replace the Feedback Package!

In Extreme Cases, Resolver in this Feedback Package Locks-Up and Breaks Resolver Coupling, Causing Axis to "Run-Away", which is Dangerous!

Broken Resolver & Tach Wires, and Loose

Cable-Connectors can also Cause these Problems.

When in Doubt, Replace the Feedback-Package!

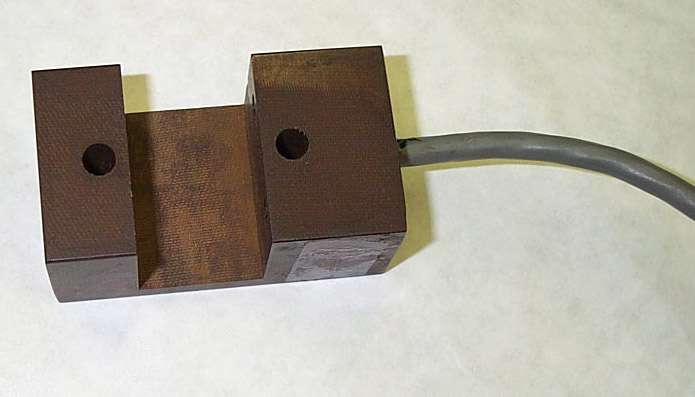

Here is the #400767-000 Sensor Switch that senses whether Shotpins are In or Out on FC750 Machines.

Two are used, 1 for Upper-Shotpin and 1 for

Lower-Shotpin. And Each Sensor is really 2 Switches,

1 for Shotpins-In, and 1 for Shotpins-Out.

There are Several Problems with this Sensor.

1 -- It is a Optical (infrared light beam) switch, so as dirt,

oil, and grease Accumulate on it, the 2 light beams are

blocked and it stops working. Its location makes it Very Hard to Clean. Use Cotton Q-Tip Swabs and

Rubbing Alcohol to clean out the 4 sensor holes.

Do NOT use a Stronger Solvent or you will Melt Optics!

2 -- It Wears Out! While solid-state electronics do not

burn-out like a light bulb, the infrared emitter's output decreases over time, so after a few years, it becomes

more Intermittent until it does not work at all. It is potted in epoxy, so it can Not be repaired, it must be replaced.

3 -- Custom-Made by Strippit (No Longer Available), there

are no other Sources to buy it from, and was Expensive.

2 Sensors, Upper & Lower, are needed per Machine.

Because of these Problems, we developed our

FC750 Shotpin Sensor Retrofit Kit using 4 Special Sensors to detect Shotpin-In and

Shotpin-Out Positions. Advantages Are;

1 -- Dirt, Oil, and Grease Do NOT Effect it,

Needs No-Cleaning Ever!

2 -- It Does NOT "Wear-Out" over time.

3 -- It Costs Less than Original Sensor Switche.

4 -- Has LED Light on End of each Sensor to

tell you when its On or Off.

This is Great for Set-Up & Troubleshooting!

Note, FC750/2 Machines used a Completely

Different Shotpin Sensor Set-Up, using a 1/4" Dowel-Pin attached to Each Shotpin with a #17441-000 Magnet on End, which activated

2 -- #18122-000 Sensors for In & Out Sensing.

#18122-000 Sensors have been replaced with

#18122-RET Retrofit Sensor Kits.

From 1970's to late 1980's, Strippit used 2 of these Duel-Optical Vane Switches to provide No-Punch Zones to protect Workclamps from being "Punched". Usually 2 switches were used, 1 on X-axis

and 1 on Y-Axis. When a X switch was blocked, a Workclamp was near X Punch-Centerline.

If a Y switch was blocked, you had Y-Axis and Workclamps all the way in near Y Punch-Centerline.

Switches are Wired-In-Parallel, so that Only if you had BOTH Sensor Switches Blocked, would you

create a "No Punch Zone" where Machine Would Not Punch, saving Workclamps from damage.

Note, some late model FC1000/3 & FC1250 Machines used only 1 switch, on the X-Axis only.

They used a X-axis sensor and Known Y Position in Control's Software to create "No Punch" Zone.

Each sensor block is really 2 Optical (infrared light beam) switches, 1 for 3 1/2 inch Large stations, and 1 for 1 1/4 inch Small stations, so we have both Large and Small No-Punch Zones.

Sensors have Several Problems;

1 -- Clearances between the 2 Metal Workclamp Vanes and Sensors are Very Small. Make sure

that Both Workclamps Vanes go through the 2 Switch-Slots Without Touching Anywhere!

Check Weekly, or even Daily!!! If Vanes Hit, Expensive Sensor is Destroyed, Vanes are Torn-Up, Mounting Screws are Sheared off, etc. Its expensive and a real-pain to properly repair.

Loose Workclamps are a Major cause of Vane Crashes.

A Smashed No-Punch Zone Sensor is the Most Common Failure there is on Machines!

2 -- Sensors can get oily and dirty, which will Block light beams, giving a False No-Punch Zone.

Gently Clean the 4 Small Sensors Tips with Q-Tip Cotton Swabs and Rubbing-Alcohol.

Do Not use a Stronger Solvent which will Melt Sensors!

3 -- Reflected Light can Activate sensors even when blocked by Workclamp or Y-Axis Metal Vanes,

allowing you to Punch your Workclamps. Clean Metal-Vanes with Solvent, then Paint with

Flat-Black Spray Paint. Do NOT get any Paint on Sensors!

4 -- Sensors were Custom-Made by Strippit, so they are Expensive! We now Manufacture and sell them at a Lower-Price. And We Include Set-Up Notes & Information With Our Version!

We have Improved this Part as Our Sensors have .500" Wide Sensor Slots, which means you have More Clearance and are Less Likely to Hit Sensor than with Strippit's .375" Sensor Slot.

Note! Old Strippit Manuals list this Sensor as Part #102361- 000 which was Original 12 Volt Only Version. This is a Obsolete Part Number and is No Longer Made.

It was Replaced by the New #102361-100 Version which will work on Both 12 and 24 Volt Machines.

When Calling Us, ask for #102361-100 No-Punch Zone Sensor, Which We Stock!

If Both Sensors are in Good Condition (Not-Hit) & Clean, and you Still get False "No-Punch Zone" Error Messages or no Messages when you should, then you probably have a Machine or Control Signal Wiring Problem or a Control Circuit Board Problem.

Specifically a "Machine Switch Isolator" Board (Slot #9) on HECC80/1 Controls,

or "TB-230 Input Isolator Board" and "G/P I/O Board" (Slot #12) on HECC80/3 Controls.

This page was last updated on: January 15, 2026

Machine Technologies Sells this #17546-000 Resolver Feedback-Package

on a Exchange-Basis, Or

You Can Pay 3 Times As Much From Strippit at $2216.00+ for a Exchange!!!

This is Kind of a "No-Brainer" Decision, Don't You Think?

Above is Our New Replacement Keyboard for Strippit HECC80/30x Controls.

Just Drill 2 Mounting Holes, Bolt to Control, Plug-In the Cable, and You Are Done!

Machine Technologies Co.

Strippit Repair-Parts

and

Strippit Machine & Control Service

Phone: 704-

233-5229

More Information

is on our Contact-Page

Here Are Some "Hard To Find" Strippit Control Parts We Stock!

NOTE !

ALL HECC80 Control Keyboards & Keypads Used

Magnetic-Switches, NOT Mechanical Switches.

Hitting Keys "Harder" to "Make Them Work" Will Only Break Switches!!!

And, Do NOT Spray "Electronic Cleaner Solvents"

into Keypads & Keyboards to Try to "Clean" or "Fix It" !

This Will MELT Key Switches and Destroy the Keypad or Keyboard !

If Keyboard Does Not Work, Send-It-In to Us to Be Repaired or Replaced!

#102361-100 Workclamp No-Punch Zone Sensors

Under the HECC80/30x Control's CRT Monitor Display is the

#401390-000 8-Key "Softkey Keyboard", as Shown Above.

There were 2 Slightly Different Versions Made, both are Interchangeable,

though you May need to Modify the Mounting Bracket a Bit.

In Photo Above, Top Keyboard is the Later Type, Made with the "B" Revision Circuit Board. There are 3 Metal Stand-Offs to Hold the Circuit Board Correct Distance from Sheetmetal Mounting Bracket. Bracket is also sort of a "Box" with 4 Folded-Up Sides.

Lower Keyboard is Earlier Type, Made with "A" Revision Circuit Board. It does Not have the 3 Stand-Offs, and Mounting Bracket Extends Out the Bottom and has 2 Slots.

Cheap Chinese Imports have Caused all the US Keyboard Manufactures to Close.

BUT, We still have a few New Softkey Keyboards Available!

AND, We Do Have The Special Parts to Repair These Special Keyboards!

Sensors & Magnets

On Above Left is #18122-000 Sensor, For the HECC80 CNC Control Machines Only!

On Above Right is #17792-000 Sensor, For the "A-Type" NC Control Machines Only!

In the Middle are #17441-000 Sensor-Magnets that work with Both Sensors.

These Sensors & Magnets were used on Most Strippit Machines Built from 1975 to 1987,

For "Ram-Up", "Brake-On", "Clutch-Off", and "Tool-Doors".

These Sensors are No Longer Manufactured, and availability is very Limited!

See Our Replacement #18122-RET Sensor Retrofit Webpage!

We have

CRT Monitor Displays In-Stock

AND

LCD-Displays

for Your Strippit HECC80/30x Control!

We Stock All

HECC80 CNC Control Circuit Boards

and all

General Electric Model 2, Model 3, Model 3A

Hi-Ack Servo Drive Boards

Strippit has been Telling Their Customers that

General Electric Servo Drive Parts are

"Not Available". It's Not True!

We Have Plenty of

#22648-000 Power-Module G.E. 44B295239-G05

#22645-000 PWMC7 Board G.E. 44A297086-G03

#22646-000 PWMC8 Board G.E. 44A297087-G03

In-Stock!!!!

Note! Original #17623-000 Strip-Sensor and #17623-300 Retrofit Strip-Sensor

are NO Longer Available!

Click-On Button at Right for Current

#17623-500 Strip-Sensor Retrofit Kit!