Strip-Sensor

Problems, Fixes, and New Retrofit Sensors

for Strippit HECC80 Turret-Machines

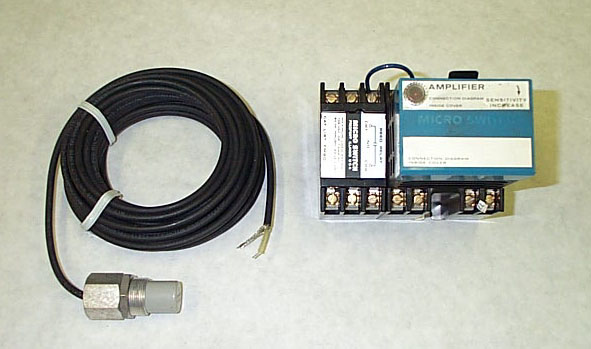

Shown Above is Original Microswitch #17623-000 Strip-Sensor and

#17624-000 Strip-Amplifier (Blue-Box) and #17609-000 Strip-Relay Assembly.

All 3 Parts were Needed to make a Complete Strip-Detection System.

These Parts were used on almost all NC & CNC Strippit Turret Punch-Press Machines

built from 1975 to 1987 for Punch-Tool Strip-Detection Circuit.

The Classic Symptom,

If your Machine will Not "Contour-Nibble", your Strip-Circuit is Not Working!

If you have a Constant "No-Strip" or "Slow-Strip" Message and Punch-Tool is Up (Stripped),

your Strip-Circuit is Not Working!

These Microswitch Parts are No-Longer Manufactured and are

No-Longer Available Anywhere as they were Discontinued in 1994.

These Parts have been Replaced by Machine Technologies Co.

#17623-300 (Discontinued) and Current #17623-500 Strip-Sensor Retrofit Kit as Shown Below.

This Sensor has been DISCONTINUED! These Old Instructions are Just for Reference!

This is Machine Technologies Co. Simple #17623-300 Strip-Sensor Retrofit Kit

that Replaces All the Old Strip-Sensor & Blue-Box Amplifier & Relay Assembly Parts.

Just Order Machine Technologies Part #17623-300.

Installation is Not Hard, and Detailed Instructions are Included.

Old Sensor and Blue-Box and Relay Assembly are Removed,

New Strip-Sensor Installed, and then you hook-up Sensor's 2 Wires.

As Before, The Gap Between Strip-Sensor and Your 20 or 33 Turret Tool-Station Strip-Targets

should be Carefully Maintained at .110" to .125" or you Risk Crashing and Destroying Sensor!

This Strip-Sensor Kit is for All Strippit Houdaille built Controls from

the Early NC "A-Control" Types, All CNC HECC80/1 and HECC80/3 Types.

Kit is also used on CAP1000 and CAP1250 Machines With the Addition of a Small-Relay.

---------------------------------------------------------------------------------------------------------------------------------------------

This Kit was Not Designed for Fanuc Control CAP1000 and CAP1250 Machines

which also used the Old Strip & Amplifier Assembly. However, It Will Work on

CAP-Machines if a Small-Relay is Wired-In to Invert the Strip-Signal going to Fanuc Control.

Strippit's Service Dept. uses Our #17623-300 Strip-Sensor Kit

and their #8312088-000 Relay on CAP-Machines for CAP-Machines Strip-Circuit.

We Stock a Small Relay Kit with Installation Instructions, that is used with

Our #17623-300 Sensor Kit that will Work on CAP1000 & CAP1250 Machines.

Installation on CAP-Machines is Tricky and is Best Done by an Experienced Serviceman

because Cap-Machines were Wired Many Different Ways,

and the Documentation and Electrical Prints were VERY Poorly Done!

---------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------

Problems and Fixes

Assuming that you have No Mechanical-Problems or You Already Fixed Mechanical Problems

with Tool-Lifters, Strip-Targets, Lifter-Springs, Lifter-Studs, Tool & Die Problems, Etc.,

In General,

Electronic Problems with the Strip-Circuits will be Caused By;

1 --- Smashed or Burned-Out Strip-Sensor

2 --- Misadjusted Strip-Sensor, Maintain Gap of .110" to .125" on ALL 20 or 33 Strip-Targets!

3 --- Smashed or Burned-Out or Misadjusted #18122-000 Ram-Up Sensor.

It is Little-Known that a Bad Ram-Up Sensor Will Also Cause "Bad-Strip" Problems!

This is Because when Punching,

Control is Suppose to "See" Strip-Signal Before it "Sees" the Ram-Up Signal.

If you have a Damaged "Shorted-Out" Ram-Up Sensor, you will get a "Slow-Strip"

because Control will Always "See" Ram-Up Signal Before Strip-Signal, Not After.

4 --- Mis-Wiring of Strip-Circuit when Replacing a Part, if Installed or Wired Wrong,

You Can Instantly Burn-Out Sensor! We Test ALL Sensors Good Before Shipping,

If you Burn-It-Out you will Need to Buy another Sensor.

5 --- Bad Machine Switch Isolator Circuit Board (Slot #9) in HECC80/1 Type Controls.

Machine Technologies Can Test & Repair this Circuit Board.

6 --- Bad TB240 I/O Isolator Board or G.P. I/O Board (Slot #13) or

Ribbon-Cable Between Boards in HECC80/3 Type Controls.

Machine Technologies Can Test & Repair these Circuit Boards.

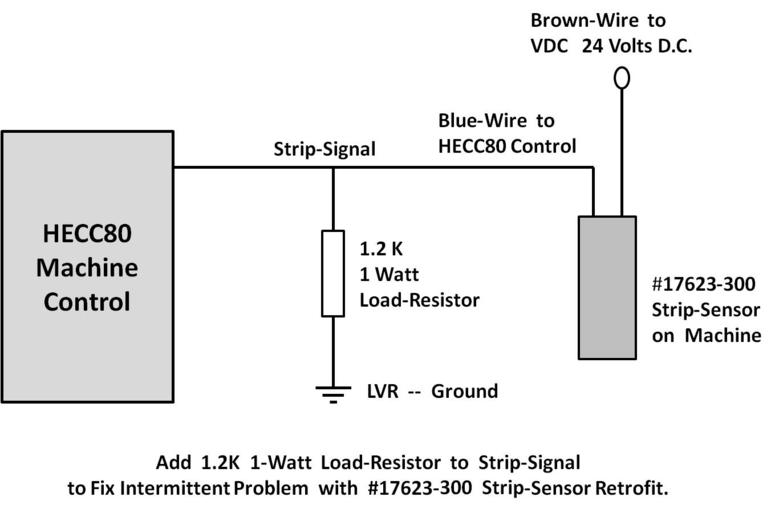

7 --- No 1.2K Load-Resistor Added to Strip-Sensor Signal Output on HECC80 Controls.

This is a Fairly Recent Change! Most HECC80 Control Machines do Not have this Resistor yet.

------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------

A Known Strip-Retrofit Problem and Fix

Machine Technologies Co. has Sold Hundreds & Hundreds of #17623-300

Strip-Sensor Retrofit Kits Directly to Shops and to Strippit Company over the last 30+ Years.

In almost all case, #17623-300 Retrofit Kit has Worked Perfectly.

However, we have found a few Cases were it will not work.

Our Investigation has found that on some HECC80/1 Type Controls, usually when we have

Rebuilt Machine Switch Isolator Board (Slot #9) and Installed New Opto-Isolator I.C. Chips, that

Machine Switch Isolator Board is now Too-Sensitive and will not work 100 percent of the time.

An Easy Fix to this Problem is to Simply Add a

1.2K 1-Watt Load-Resistor to Strip-Signal coming out of Strip-Sensor going to HECC80 Control.

In Every Case This has Fixed the Problem.

I have Only seen this Problem in HECC80/1 Controls, Not in HECC80/3 Controls,

but I would Add this Resistor-Fix to Both Types of HECC80 Controls!

Go to our Strippit Control Type Web-Page if you are Not Sure of Your Control Type!

We started Adding this Resistor to our Machine Technologies #17623-300 Strip Retrofit Kit

with Installation Instructions a Couple of Years ago.

Typically, on FC1000/2 or 20-Station FC1250/30/1500 Machines, we Add Resistor in Big Electrical Disconnect Box on Side of Machine between Terminal 2TB-42 Strip-Signal & Terminal LVR (Ground).

This Wiring Will Vary from Machine to Machine, so Consult your Machines Electrical Prints!

If your HECC80 Control Machine Does Not have Resistor Installed, it Should be Added!

We Include this 1.2K Resistor in All Strip-Sensor Retrofit Kits!

Resistor Only needs to be installed 1 Time, as in Diagram Below.

This page was last updated: June 18, 2025

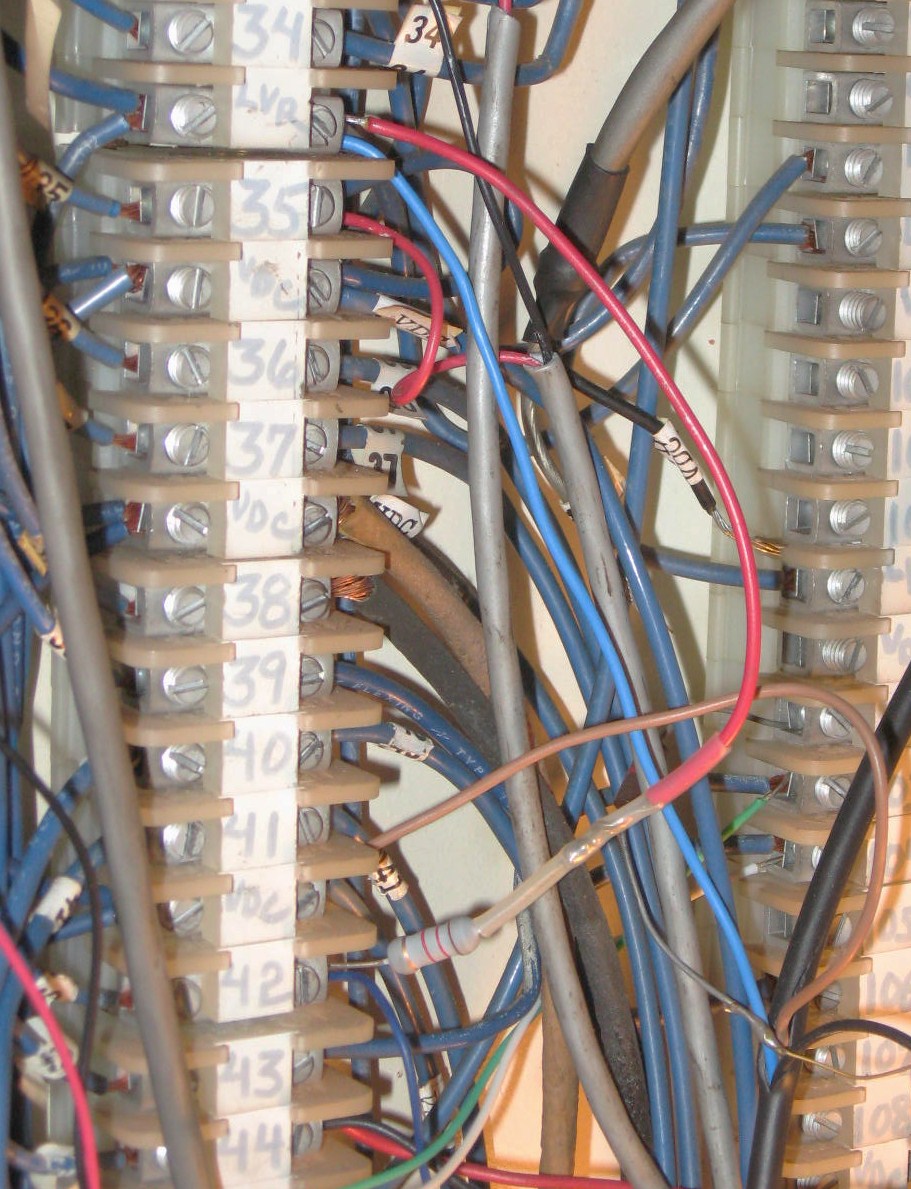

For Example,

here is the 1.2K Resistor

added to my FC1000/2 Machine.

Blue-Wire from Strip-Sensor

comes into Terminal TB-42

inside Electrical Disconnect-Box.

I Soldered a

Red-Wire to End of Resistor

to Lengthen it so that it could reach a

LVR (Ground) Terminal.

Resistor Simply goes between

TB-42 Strip-Signal Terminal

and ANY Convenient

LVR (Ground) Terminal.

That's it, End of Fix!

-----------------------------------------------------------------------------------------------------------------------------------------------

So, To Recap,

When Using #17623-300 Strip-Sensor Retrofit;

--- Add Resistor to All Machines using HECC80/1 Type Control

--- Add Resistor to All Machines using HECC80/3 Type Control

--- Do Not add Resistor to Machines using "A-Controls", as Resistor is Not Needed

--- Do Not add Resistor to CAP1000 and CAP1250 Machines where

Strip-Sensor is Driving the small Inverting-Relay, as Resistor is Not Needed

--- Note! Resistor is NOT Needed with Newer Type #2 #17623-500 Strip-Sensor Retrofit!

----------------------------------------------------------------------------------------------------------------------------------------------

The Original Strip Sensor;

Mircoswitch Strip-Sensor #17623-000 & Amplifier Electronic Assembly (Blue-Box) #17624-000 were used on most Strippit Turret Punch Machines built 1975 to 1987 for Punch-Tool

Strip-Detection. The Original Sensor and Amplifier are NO longer made or available anywhere!

Sensor can be Identified by Dimensions 57mm (2.25") Long x 24mm (.932") Body with Gray-Tip.

Type 1 Retrofit Sensor:

In the late 1990's Machine Technologies came up with a Simple Retrofit Sensor to solve

Old Sensor Non-availability Problem. Functions of Old Sensor & Amplifier Blue-Box were

Combined into a Special 2-Wire #17623-300 Retrofit Sensor. This Sensor can be

Identified by Dimensions 37mm (1.45") Long x 18mm (.700") Body with Black-Tip.

Note! In 2014 this Type #1 #17623-300 Sensor was Discontinued and is No Longer Available.

It has been Replaced with Machine Technologies Type #2 #17623-500 Retrofit Sensor.

Type #2 The Current & In-Stock #17623-500 Retrofit Strip Sensor:

Starting in 2014 Machine Technologies Co. introduced Type #2 3-Wire #17623-500 Retrofit

Strip Sensor that Replaces Both Original #17623-300 & Type #1 #17623-300 Retrofit Sensor.

Sensor can be Identified by Dimensions 57mm (2.25") Long x 18mm (.700") Body with Black-Tip.

Installation is not complicated, but it does take time, probably several hours, to

Set-up All Turret-Stations Strip-Targets Gaps Correctly.

Improper Maintenance of Turret-Station Strip-Target Gap

is what caused Your Smashed Strip Sensor Problems to begin with!

REMOVE Old Strip-Sensor & Strip-Amplifier (Blue-Box) Assembly if still on Machine! Mount New #17623-500 Strip-Sensor in place of Old Sensor, then Connect it's 3-Wires to proper terminals.

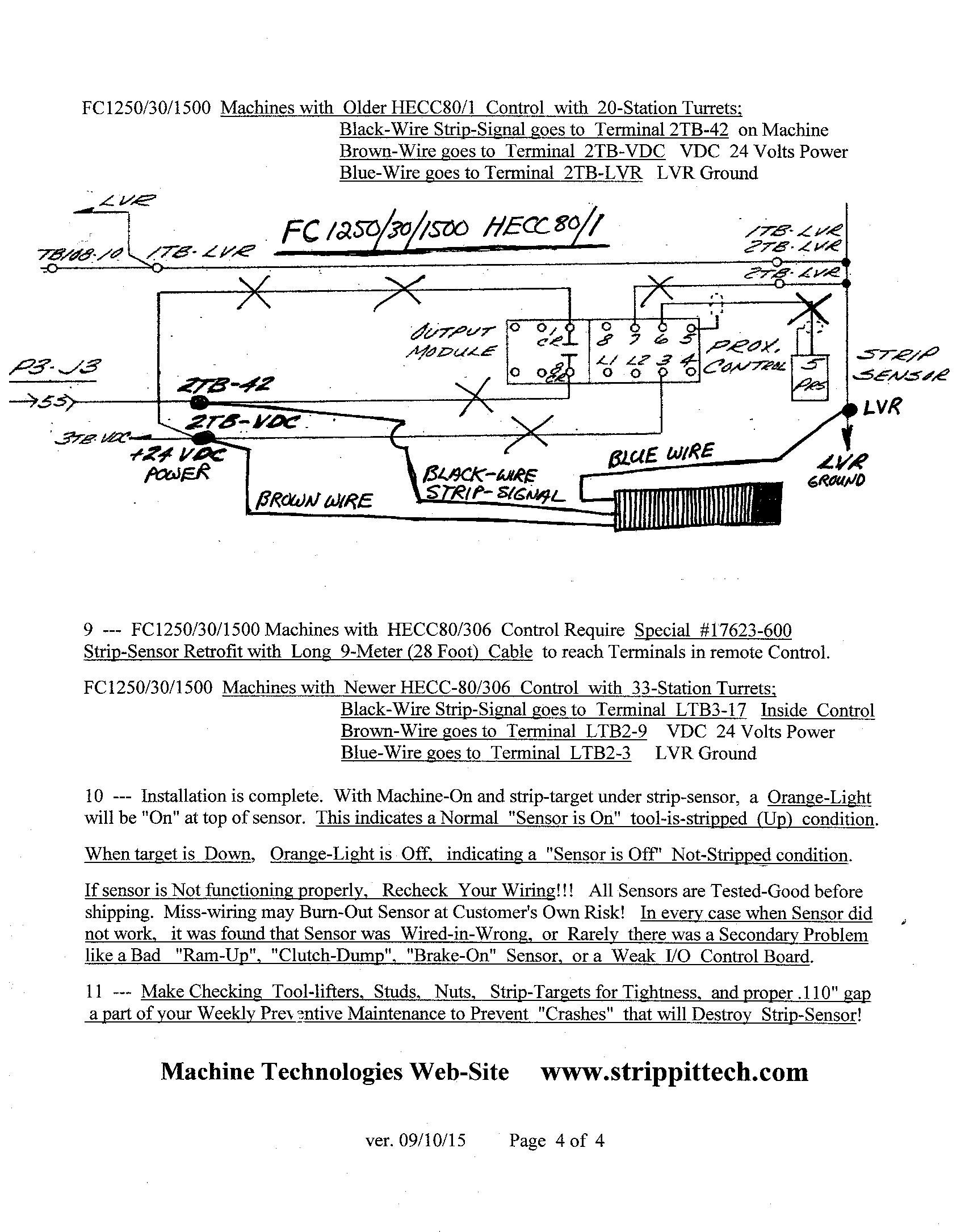

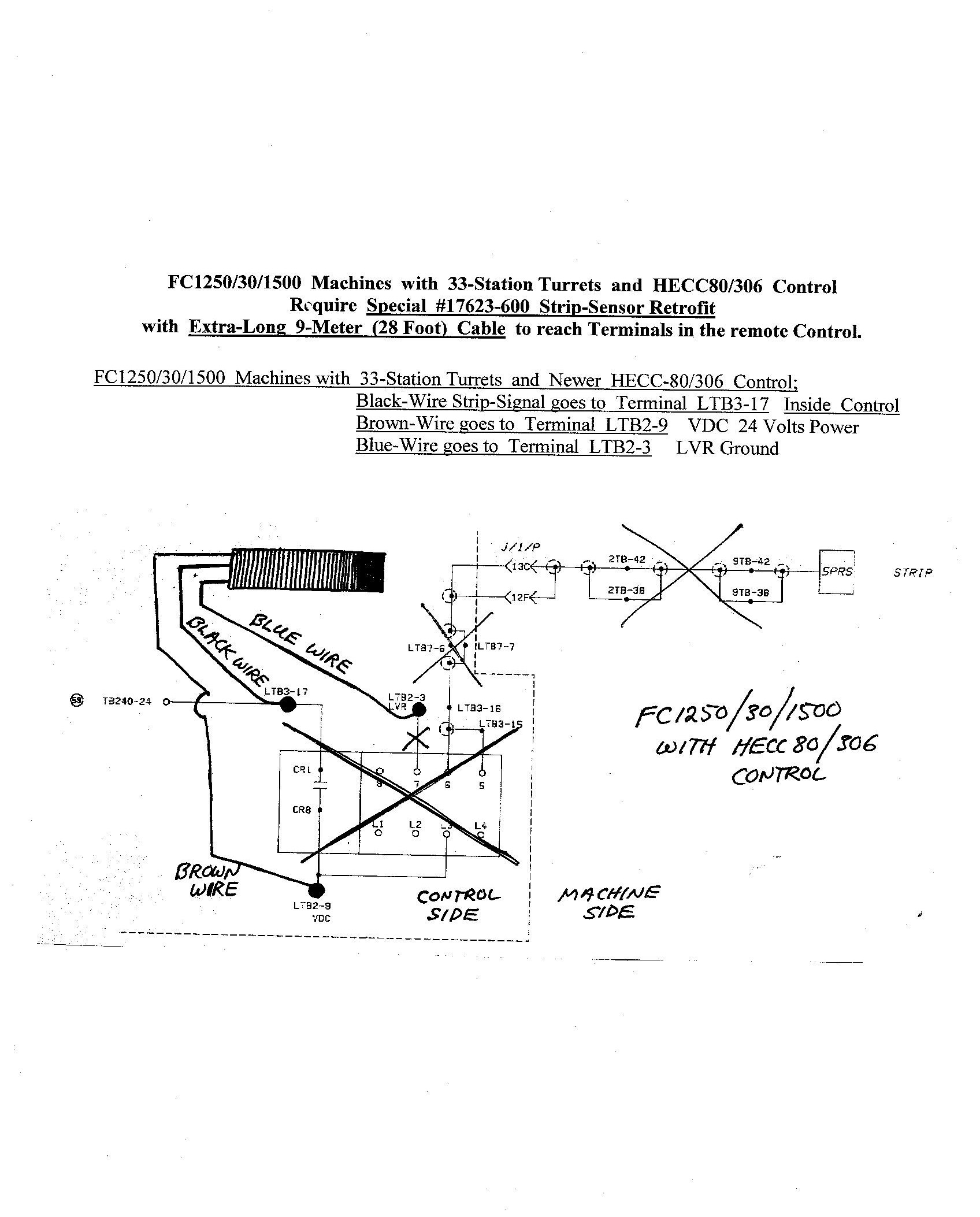

The following 5 Pages are Instructions that come with New #17623-500 Retrofit Strip-Sensor.