Sensor Retrofits

In 1970's & 1980's, the Strippit Co. used #18122-000 (1-Meter Long Cable)

and #19684-000 (2-Meter Long Cable) Sensors, both using #17441-000 Magnets,

on most of their CNC Punching Machines for

Brake-On, Clutch-Dump, Ram-Up, Upper Tool-Door, and Tool-Ring Sensor Functions.

These Hi-Speed Hall-Effect Sensors are Obsolete,

and are No longer Manufactured or Available anywhere.

As Original Sensors are Short and Compact, with Special Electrical Characteristics,

finding a Replacement Sensor was Difficult.

Machine Technologies has now Sourced, and Tested-Good,

a New Replacement Sensor and Target Combination on our Strippit Machines,

and we now offer this Retrofit Sensor and Target Kit For-Sale.

Both #18122-000 and #19684-000 Sensors will be Replaced with

Machine Technologies Part Number #18122-RET Retrofit Sensor Kit. Kit Includes

New #17441-RET Target Replaces Old #17441-000 Magnet, and is Required for

Proper Operation. Extra Targets can be ordered using this #17441-RET Part Number.

Because New Target is a little Heavier than Old Magnet Target, we have provided a

Special Kelps-Nut and Thread-Lock Fluid to Secure Target Firmly.

Just apply a Small Drop of Thread-Lock Fluid to Target-Stud before doing the

final Tightening on Keps-Nut.

If Target were to get Loose, it could Hit Sensor and Both could be Destroyed!

This Loosening was also a Problem with old Sensor & Magnet Combination.

At Left,

Obsolete

#18122-000 Sensor

and

#17441-000 Magnet

with Keps-Nut

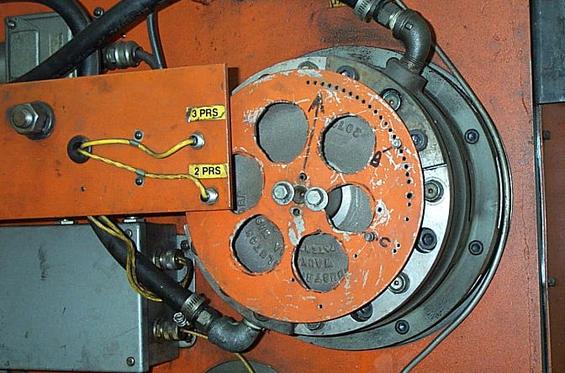

At Right,

Two Obsolete

#18122-000 Sensors

with two

#1774-000 Magnets

on Timing-Disk

being used for

Brake-On &

Clutch-Dump

Press-Drive Timing

on this

FC1250/30/1500

Strippit Machine

#18122-RET

Retrofit Sensor Kit.

Kit Includes

New Sensor

New #17441-RET Target Keps-Nut

and

Loctite 242 or 243

Thread-Locker Fluid.

Sensor Installation is Easy, and only involves 3 Wires,

But the 3 Wire Color-Codes are Different on Old and New Sensors!

Installer Must Carefully Write-Down What

Terminal-Numbers 3 Old--Sensor Wires were Connected to.

Refer to your Machine's Wiring Prints.

Typically, OLD Sensor Wiring;

RED--Wire goes to 1DC (12 Volts D.C. Voltage)

WHITE--Wire goes to Signal-Out to Control

BLACK--Wire goes to LVR (Ground)

NEW Sensor Wiring;

BROWN--Wire goes to 1DC (12 Volts D.C. Voltage)

BLACK--Wire goes to Signal-Out to Control

BLUE--Wire goes to LVR (Ground)

Double-Check Your Wiring BEFORE You Turn-On Control Power!

All Sensors are Tested-Good Before Shipping.

Sensor Wiring Errors may Burn-Out New Sensor and will be at Customers own Risk.

Set Gap between NEW Retrofit Sensor and Target to .040" (1.0MM),

use a Feeler-Gage to Set Gap Correctly,

and make sure Sensor to Target Alignment Left to Right is Correct.

When Sensor is Over Target,

Sensor will be "ON" and small LED-Light will be "ON" at Cable-End of Sensor.

As some readjustment of Sensor and Target Positions & Gaps may be needed,

do not use Thread-Lock Fluid until you are Satisfied with Machine Operation.

Then go back, remove Keps-Nut, put a small drop of Thread-Lock Fluid on Target-Stud Threads,

and Firmly Tighten Keps-Nut.

This page was last updated: June 12, 2025

Ram-Up Application

When using Sensor in Ram-Up Application, make Sure that Punch-Ram is All the way Up

into the T.D.C. Top-Dead-Center Position Before you set Sensor and Target Gap.

If Not Properly set at T.D.C. Position, Target will Crash into Sensor, Destroying Both.

There is usually a "Mark" or "Notch" on Timing-Disk to Indicate T.D.C.

This Mark will be at the very Top 12 O'clock Position when Press-Drive is at T.D.C.

If Punch-Ram is Not at T.D.C.,

Push-Down and Twist-to-Lock Activation Button on Brake MAC Valve to Release Brake

which is holding Press-Drive in position. Now you can grab Timing-Disk by hand, and

Rotate Timing-Disk Back--and--Forth until Mark is in T.D.C. Position.

Release Mac Valve to Hold position.

Now set NEW Retrofit Sensor & Target Gap to .040" (1.0mm).

If still using OLD Sensors & Magnets, set Gap to .025" (0.63mm)

Setting Clearance Gap on

Clutch & Brake Timing Sensors & Targets / Magnets

1 -- Rotate Turret, by Hand if necessary, so there is No-Tool under the Ram.

2 -- With Machine Power Turned-Off, take a small screwdriver, Push-In and Twist

Actuator-Button on Brake Mac Air-Valve to Lock-On & Activate Air-Valve,

which will Release the Brake. This will allow Crankshaft to be Rotated.

3 -- Grab Aluminum Timing-Disk with Both Hands, and Push & Pull Hard on it.

If you feel a "Clunking" as you Push & Pull,

This is Slop & Wear in End-Bearings allowing Crankshaft to Move Back & Forth.

End-Bearing Wear can cause Improperly-Set Sensors and Magnet / Targets

to "Crash" and be Destroyed.

End-Bearing Wear is Caused by Shop Knuckleheads putting Wrong Oil in Press-Drive

Lube-Tank when Machine Stops with a "Lube Failure" Fault caused by Empty oil tank.

Knucklehead's then Grab the First Oil-Like Substance they can find,

Usually Hydraulic Fluid, and then dump that into Tank, instead of Proper Lubricating Oil.

Read about Lube System & Correct Lubrication Oils on

4 -- Grab the Timing-Disk, and Rotate Disk (and the Crankshaft) until

Clutch-Off ( Inner-Track Target / Magnet) Target / Magnet is over it's Sensor.

Make sure Sensor & Target / Magnet are Aligned Closely Left to Right,

and are NOT Off-Set to each other. Fix if necessary!

5 -- Push Disk Hard to Take-Up the Slop between NEW Retrofit Sensor & Target ,

then Set Gap Between Them to .040 inch (1.0mm).

If still using OLD Sensors & Magnets, Set Gap to .025" (0.63mm).

This way, Crankshaft can Only Drift Magnets & Targets AWAY from Sensors

and NOT into them, to Avoid Breakage of Sensors & Targets & Magnets!

6 -- Repeat with Brake-On (Outer-Track Target / Magnets) Sensor & Target / Magnets.

7 -- Rotate Ram Back-up to Top-Dead-Center (T.D.C.) and release Brake Mac Air-Valve.

8 -- Turn-On Machine, and "Punch" a couple of times.

Ram Needs to Stop Consistently at Top-Dead-Center (Notch at 12 O'clock) Position,

or Better-Still, a Bit Before at the 11 O'clock Position!

If Ram Stops-Too Early, Retard the Brake-On Target / Magnet a Couple of Hole Positions.

If Ram Stops Too-Late, Advance the Brake-On Target / Magnet a Couple of Hole Positions.

If you cannot get Ram to Stop at T.D.C., there may be Other Issues such as

Worn Brake & Clutch Assemblies, Sticking Clutch & Brake Mac Valves, Broken Clutch Poppit Valve, Clogged Air Filters, bad Air-Regulators, Etc., that Will NEED to be Repaired!

Off to See