Strippit Machine Servo-Drive Motors

The Strippit Company used D.C. Brush-Type Servo Motors on all their HECC80 CNC and "A" NC Control Turret Punch Machines Manufactured in the 1970's & 1980's.

This discussion will pertain Specifically to Servo Motors that were used on

Strippit Machines of this Era. They are Typically Tagged as

Porter / Peerless / Porter Peerless / General Electric / Magna / or

Machine Technologies on the Motor Name-Plate.

I Stock, Here at Machine Technologies, All these Servo Motors, and I Can Provide

Motor Testing, Rebuilt-Exchange Motors, Rebuilding of Your Motors, & Repair Parts.

Later-on, in 1986 on FC1000/3's, and in 1987 on the FC1250/30/1500 Machines,

Strippit started Converting from HECC80 Controls to Fanuc GN6 CNC Controls,

which used Fanuc's Own D.C. Servo Drives & Servo Motors.

Around 1989, Strippit Converted again to New Fanuc OP Controls, which used a

Newer & Superior Motor Technology, A.C. Servo Drives & A.C. Motors.

A.C Servo-Motors & A.C. Motor-Drives are Superior Technologies,

But God Help You if you Need to Replace one of these Fanuc Motors,

because Fanuc often Quotes Months Delivery and Costs of $10,000 to $25,000!

I Do Not Repair or Stock Any Fanuc Motors at this Time.

Following are DC Servo Motor Types, and the Strippit HECC80 Control Turret Punch Machines that they were Used On. Some Motors were Also used on Other Machines.

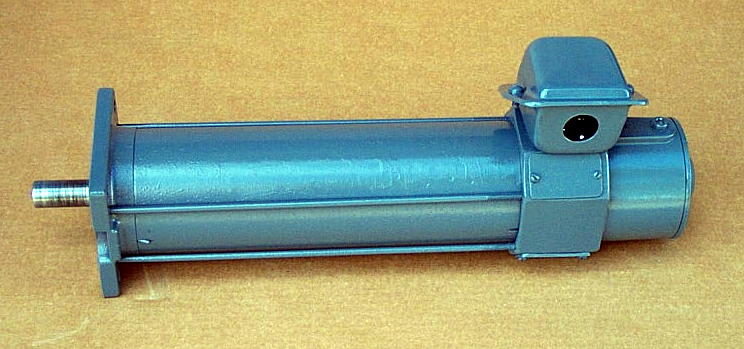

Strippit #17539-000

Model #181-04-0020-0

Used on T-Axis of FC1000/1, FC1000/2,

and FC1250/30/1500 Machines with

20-Station Turrets. But is Not used on

33-Station FC1250/30/1500 Machines.

This Motor is the Same as #17497-000 Motor, Except it does Not have Air Cooling Ports. You can Substitute a

#17497-000 for a #17539-000 on a

T-Axis, but you can Not Substitute a #17539-000 for a #17497-000 on a X-Axis

because of the Lack of Cooling Ports.

Brushes & Caps are Same as #17497-000.

Strippit #17497-000

Model #181-04-0011-0

Used on X-Axis on Strippit FC750, FC750/2, FC1000/1, FC1000/2

Machines. Has a 1 1/2" Pipe-Thread Cooling-Air Inlet Port at the Back of Motor, Air goes through Motor and Out Slots at Bottom Front of Motor.

Uses 4 -- #17506-000 Brushes.

Most Motors use 3/4" Small-Disk

Out-Side Thread Type Brush Caps,

But, Older Motor Versions use

Cup-Type Brush Cap with

Inside Threads.

Strippit #17360-000

Model #181-12-0015-0

Used on Y-Axis of FC750, FC750/2,

FC1000/1, FC1000/2, FC1250/30/1500,

FC1250/30/1500 LaserTool, FC1250/45, LaserCenter, FC51/30, FC51/40,

and Blanking Center Machines.

Motors use 6 -- #17788-000 Brushes and 7/8" Disk Brush-Caps.

Strippit #17538-000

Model #181-12-0019-0

Used on X-Axis of FC1250/30/1500,

FC1250/30/1500 LaserTool, LaserCenter, FC1250/45, Old Style FC1250/30, FC51/30, FC51/40 and

Blanking Center Machines.

This is just a Shorter Version of the #17360-000 Motor.

Motors use 6 -- #17788-000 Brushes and 7/8" Disk Brush-Caps.

Strippit #17510-000

Model #183-18-0190-0

Used on the T-Axis of FC1250/45,

Old-Style FC51/30, FC51/40, and

FC1250/30 (NOT FC1250/30/1500) Machines.

Motors use 8 -- #17506-000 Brushes and Special Top-Hat Disk or the

Small 3/4" Disk Brush-Caps.

This particular Motor is a "Pull" from a Machine I Scraped, and still has it's Coupling & Special Geared Resolver Feedback Package attached.

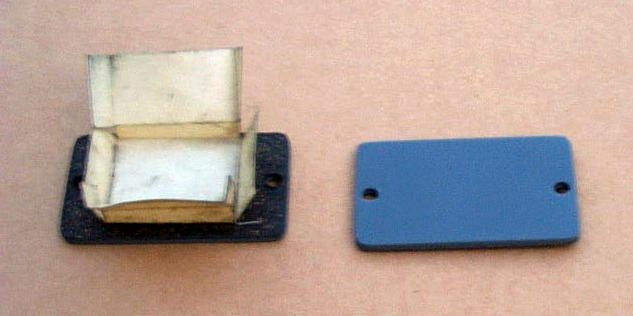

Strippit #19463-000

Model #181-04-0034-0

Used on T-Axis of FC1000/3 and FC1250/30/1500 Machines with

33-Station Turrets.

Motors use 4 -- #19463-000

"Type-C" Brushes, and have a

Steel Rectangle Brush-Cover.

Motor was also Sometimes used on

X-Axis of FC750 & FC750/2 and

X & T Axis of FC1000/1 & FC1000/2

Machines in a Mistaken Attempt at Increased Reliability. They Work OK there, but give Little Added Benefit.

I now also use this Motor as a Substitution for the #17497-000 and #17539-000 so that I only have to Stock 1 Motor instead of 3. This particular Motor is one that I Personally Rebuilt.

Strippit #19399-000

Model #191-04-0029-0

Used on Y-Axis of FC1000/3 Machines.

However, with a Bit of Grinding for Mechanical Clearances, it can be used as X-Axis Motor on FC1500/45 Machines.

Motors use 4 -- #19463-000 "Type-C" Brushes with

Steel Rectangle Brush-Covers.

Strippit #19462-000

Model #191-04-0033-0

Used Only-On the

X-Axis of FC1000/3 Machines.

Motors use 4 -- #19463-000 "Type-C" Brushes, and have a

Steel Rectangle Brush-Cover.

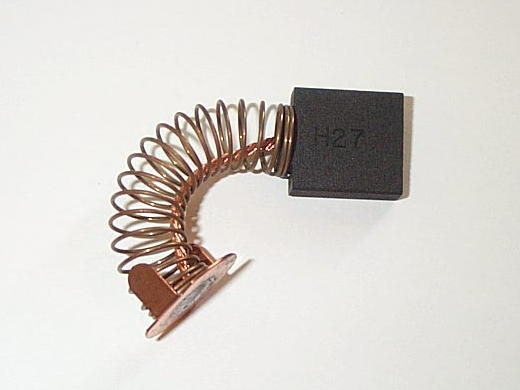

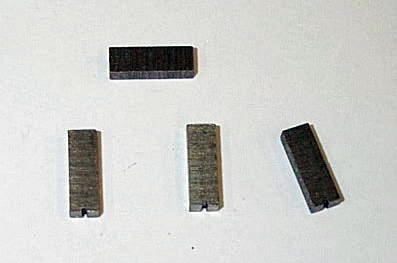

#17506-000 "Small Brush"

.250" Thick x .500" Wide x .625" Long

The Round Plastic Brush Caps used on these Motors are Easily Chipped and Broken by

Careless Removal with a Screwdriver !!! Make a Removal Tool from Thin Sheetmetal

Cut to the Width of each Caps Slot. We Stock the Following Replacement Brush Caps.

Motor Brushes & Caps

Motor Brushes should be Checked Regularly for Wear! Replace Brushes if Worn to Half their New Length. Check X & T Motor Brushes once a Year, and check Y-Axis Brushes every 6-Months. Check more often if these seem to be Wearing Rapidly.

I usually "Tag" Each Motor on Machine with It's Brush "Inspection Date",

or else keep a Repair Maintenance Log Book with this Data Recorded in it.

If you Don't Check them, Brushes will Wear Down until Carbon is Gone, Then the

Copper Wire & Steel-Spring Digs & Burns into the Commutator, Ruining Motor.

#17788-000 "Large Brush"

.250" Thick x .750" Wide x .750" Long

#19463-000

"Type-C Brush" for FC1000/3 & FC1500/45 Machines

.250" Thick x 1.000" Wide

x .875" Long

"Small-Disk" Type Brush-Cap that are

used on Most Motors that use the

Small #17506-000 Brush.

3/4" Wide with Outer-Diameter Threads

"Small-Cup" Type Brush-Caps that are

used on Old-Style Motors that use the

Small #17506-000 Brush.

13/16" Wide with Inner-Diameter Threads

"Large-Disk" Type Brush-Caps that are

used on Most Motors that use the

Large #17788-000 Brush.

7/8" Wide with Outer-Diameter Threads

Steel Rectangle Type Brush-Cover that

are used on FC1000/3 "Type C" Motors that use the #19463-000 Brush.

Early Version Covers had Cork-Insulation Glued on the Underside. Later Covers Also had a a Heavy-Paper Shield to help Protect against the Brush-Wire from Shorting against Motor Housing.

This page was last updated: June 26, 2025

(DC Generator) that tells Servo-Drive how Fast

the Motor is Rotating. A Properly Working Tach is Critical to Operation of Servo-Drive!

A Good Clean Tach Assembly, on Strippit Servo Motors, will read About 60 to 75 Ohms. Check it,

Rotate Motor Shaft a Bit by Hand, and Check it again. Repeat several times more to gain confidence that

Tach is Working OK in All Positions.

A Bad Tach will show Thousands or More of Resistance in Ohms. Usually caused by;

--- Dirty or Tarnished Tach Commutator, Clean with

Soft Pencil Eraser or Fine Scotch-Brite Pad.

--- Stuck Tach Brush. Take out Holder & Clean out

with Electrical Cleaner, and Very Lightly Sand

4 Brush Sides with 400 or 600 Grit Paper.

--- Bad Tach Armature. The Potting Compound on

Armature Shrinks with Age & Breaks Wires in

Tach Armature and then Must be Replaced!

--- Bent Tach Brush Spring. You can NOT Fix Bent

Springs! Spring or Tach Ring Must be Replaced!

Springs are Bent by Careless Brush Insertion!

I Carefully Pull-Back the Side-Of-Spring with a

Small Screwdriver while Pushing In Tach Brush

with Another Small Screwdriver, then Insert a

Piece of Paper Clip in Hole to Hold Brush in.

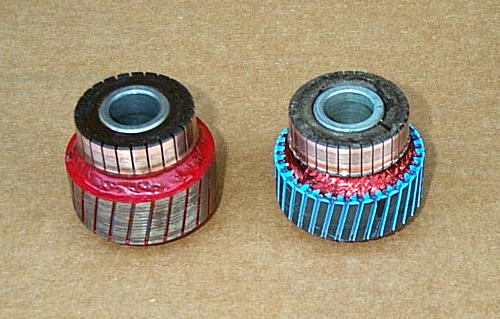

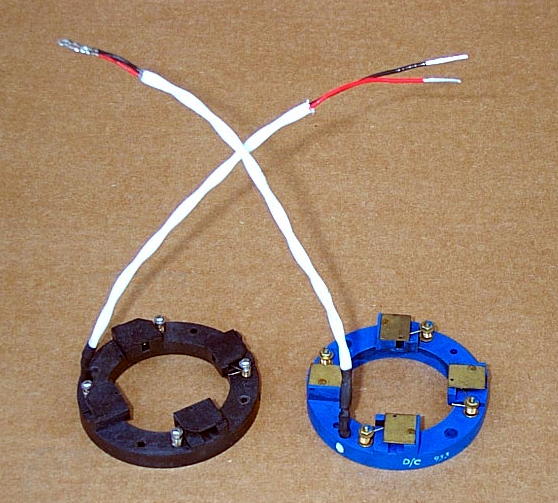

This Tach-Ring is Installed Upside Down!

Tach-Cable is Usually at the

Top of Motor.

This Motor has the Original "Blue" Type Tach-Ring

with

Original Type 25-Segment

Tach-Armature.

Tachometers

In the Good-Old Days,

there was just 1 Type of Tach-Ring & it's Armature, the "Blue" Type.

Then, there was a 2nd Type, the "Black" Type-Ring & it's "Black" Type Armature.

The "Black" Type Used a Different Size Tach-Ring, Armature, and Magnet-Set

Inside Motor, so None of the Parts are Interchangeable with the "Blue" Type!

However, as Technology Changed and Venders Come & Go, The "Color" of

Tach-Ring and Tach-Armature has become Almost Meaningless.

I have seen Blue, 2 Sizes of Black, Green, Tan, Red, Etc., of Tach-Rings!

There are really still only 2 Types regardless of the Actual Color.

I Measure Outside Diameter of the Tach Armature to tell them apart.

The "Blue" Type of Tachometer Assemblies will have a Tach Armature

with a Outside Diameter of about 1.895 Inches.

The "Black" Type of Tachometer Assembly will have a Tach Armature

with a Outside Diameter of about 1.937 Inches.

To further complicate, "Blue" Tach Armatures Originally had 25-Segments & Windings.

But, to get Better Servo Response at Low Speeds for Laser Continuous Contouring,

a New Type of Armature was Manufactured with 33-Segments and Windings.

As long as they are of the Same Type (Blue or Black) and Same Size, 25 & 33 Segment Types are Interchangeable, but with 33 Type giving Better Servo Response.

Both "Blue" & "Black" Tach Rings used Same #17774-300 Tach-Brushes.

Old Brushes were a Dark-Black Color

as they were made of a

Dry Hard Carbon that sometimes would Wear a Groove into Tach Armature,

which would Destroy it.

Later Brushes had More Graphite in

Carbon-Mix, which provided some Lubrication Properties, and would Prevent the Wear-Problem as

Machines got Faster & Faster.

These Newer Brushes were

Silvery in Color and had a Waxy Feel.

There are at Least 2

"Blue" Types of

Tach Brush Holder Rings,

Part #17774-100

The Original Blue-Color

"Blue" Type

And

a Late Manufacture

"Blue" Type that

happens to be

Black in Color!

These are Both

"Blue" Rings in Photo!

Original "Blue" Type 25

Segment Tach Armature that

happens to be Red, #17774-000

On Left, Original "Blue" Color

Tach really referred Only

to Tach Ring-Color,

NOT the Armature Color.

On Right, a Late Manufacture

33-Segment "Blue" Type Armature used in Later Motors.

Here is the Real

"Black" Tach Ring #17774-500.

And, it's #17774-400 "Black" Type Armature.

I Believe that all

"Black" Tachs used only this Type 33-Segment Armature,

which is Different from the "Blue" 33-Segment Armature.

Note! Most Motors used the "Blue" Tach. I Believe The "Black" Tach was only used

on some Later #17360-000

and #17538-000 Motors.

Motor Killers

Above are 2 Armatures from Stalled Servo Motors that got So Hot that

Plastic Insulation Melted and Oozed Out of the Armatures!

This Starts to Happens at about 400 Degrees Fahrenheit! The Magnet-Wire Insulation Breaks-Down, Windings Short & Arc Together, and Motor becomes Junk.

Here are Some (But Certainly Not All) of the Causes of Servo Motor Failure;

1 --- The Biggest Cause of Servo Motor Failure is Heat.

When a Motor is Stalled, it Pulls Maximum Current,

which can Overheat and Burn-Out a Motor in only a Minute or Two,

if Operator is Not Smart Enough to Quickly Shut-Off Machine and Clear the Jam-Up!

--- Some causes are a Jammed X or Y Axis. This Occurs when Machine Pulls a Slug

Jamming Part-Sheet, or a Punch Sticks-Down causing a Jam With a Short

(Under 3 Inches) Axis Move so the Control does NOT Declare a "Excess Error" which would Shutdown Servo Drive. So, Control keeps Powering Stalled-Jammed Motor

to Move. If Operator does Not Quickly shut off Machine, you Risk Burning the Motor.

--- Sometimes X or Y Axis Limit Switches are Not Working, or some Knuckle-Head "Adjusted" Switches to try to get a Little More Travel Length on Axis. Then, if you

have a Operator Error, or Programming Error, or Control Failure that causes Axis to

Hit the End of Axis-Travel, you Stall the Motor like Above, and Burn Out Motor.

--- Similar Motor-Killing Jams on Turret from;

--- Pulled-Slugs Jamming Turret to Part-Sheet,

--- Too-Tall Tool Hitting Ram,

--- Jammed Part-Sheet still Stuck to a Tool,

--- Slugs in Gears,

--- Slug Jammed between Lower Turret & Anvil Underneath

When a Jammed Turret tries to make a <3" Short 1-Station Move, there will be

No Excess Error Condition to Stop Control from Driving the Servo Motor.

Jammed Turret causes same Stalled Motor Burn Out Problem as Motor Overheats in a Couple of Minutes while Operator is Still Scratching His Head on What's Wrong......

Also, FC1000/1 & FC1000/2 & FC1250/30/1500 Machines with 20-Station Turrets

Rarely Burned-Out T-Motors because Strippit used a Small 8.67 Heater in the

T-Servo Overload-Relay to Protect Motor. When Jammed, Heater would

Quickly Heat-Up & Trip-Out similar to a Circuit-Breaker and Saving the Motor.

But, when Strippit changed to 33-Station Turrets, they Changed Heater Size to a

Large 21.4 Heater that would Never trip-out before Motor Melted! I sometimes

change 21.4 Heater Down to about a 10.0 to 13.00 Size to help prevent this problem.

FC1000/3 Machines with G.E. Model 3 Servo used a Electronic Overload instead of

the Heater & Overload-Relay as it was Cheaper for G.E. when building Servo Drives.

But, Electronic Overloads NEVER Trip to Save the Motor on these Machines!

I sometime Retrofit the old Heater & Overload-Relay on to these Machines, in the Field.

Last Project I Did before Leaving Strippit was Designing Overload-Relay Retrofit

which Strippit Added to Production FC1000/3 Machines Starting at Serial Number 200.

These Same Technicians Then think a Megohmmeter is The-Answer,

and will tell them a "Bad" Motor.

In Most cases, this is Also Wrong!

A Ohmmeter puts out about a Volt or 2, and then Measures Current Flow,

to Determine the Resistance of a Circuit.

A Megohmmeter uses a Hi-Voltage to do the Same thing. My Megohmmeter at

Left can Put-Out Over a Thousand Volts!

The Idea is, at Hi-Voltage, Weak, Bad,

or "Cooked" Insulation will Break-Down

and the Megohmmeter will Detect it.

But, You usually can Not Read Insulation

Breakdown, Winding to Winding, with

Either Type of Meter! Both Melted &

Shorted Armatures in Picture Above will

Pass Megohmmeter Test at the Highest

1000 Volt Setting, yet are Quite Bad!

The Magnet Shell

at Right Got So Hot

that Glue that Holds Magnets inside

Broke Down, and all

Magnet-Segments came out when Motor

was Disassembled.

It's Junk Now Also.

Some Technicians try to Determine a Shorted or Burned-Out Motor with a Ohmmeter.

You Can't!!!

Most Motors Burn-Out by Shorting their Windings Together,

and You Can Not Ohm-Out This Problem!!!

These Technicians Also Meg the Armature to Ground.

As there is Always Dirt and Carbon Dust Coating Inside of Motor,

they Will Always get a "Reading".

They then Declare Motor is "Shorted", and send it out to be Rebuilt.

The Motor Could Indeed be Bad,

But This Test will NOT Prove it One Way or the Other,

as this is NOT the Normal Failure Mode!

3 --- Another Common Cause of Motor Failures is Worn-Out Brushes.

Customers Fail to do Routine Maintenance like Checking their 3 (X, Y, T) Servo Motor Brushes, which then Wear-Down Until they Destroy the Motor Commutator,

and possibly also the Servo Drive Electronics.

I can Sell You New Brushes or I can Sell You Motors & Servo-Drives. Your Choice.

Below Photo Shows a New Brush on the Left, and 3 Worn-Out & Broken Brushes

I Dug-Out of a Customer's Motor. They got to Buy a New Motor.

4 --- Another Common Cause of Motor Failures is Impact Damage.

Motors are Relatively Fragile. Impacts can Break the Magnets Loose inside Motor,

Pull Out the Studs Holding Motor Together, and Break Resolver Feedback Package Off the End of Motor, among other Failures. People in Shops Run Into Motors with their Fork-Lifts and Bump them with Work-Tables. Put Guard-Rails around Machine!

Replacement Motors and Motors being Returned for Credit are Often Damaged by Shipping! They Must be Very Well Packed in a Heavy-Duty Carton with Lots of Tight Packing Materials. I Now Double-Pack the Bigger Motors inside 2 Boxes!

I often get a Return Motor Back that was just Thrown into a Box with Little or No

Packing Material around it, and it comes-in with Part of Motor Sticking Outside of Box!

Needless to say, These Damaged Motors Do NOT Receive Any Credit for the Return.

2 --- More Motor Heat Failures are caused by No Cooling Air-Flow.

The X & Y Motors, and the T Motor on some Machines, are Forced Air Cooled.

-- Is there a Strong Air-Flow coming out of Motor?

-- Is the Cooling Fan Motor Running?

-- Is the Air Filter Clogged-Up?

-- Are the Air Hoses Rotted out?

Find and Repair the Above Problems!!!

5 --- Local Motor Shops Permanently Kill a Lot of Servo Motors.

When a Shop Burns-Out a Servo Motor on one of their Machines,

they usually try to go Cheap, and "Give the Local Motor Rewind Shop" a Try.

The Problem Is, Most Motor Shops are Set-Up to Rewind Only A.C. Motors,

NOT D.C. Servo Motors, which are Very Different!!!

These Motor Shops Always Do 1 of 2 Things;

A --- They Take Apart Motor and Damage Armature & Tach-Armature & Magnet Shell Further. They then "Cut" Commutator, usually Improperly, which Ruins this Critical Part. Finally, they replace Bearings, Cut-Down and Adapt some Brushes to Fit,

Paint It, and Declare it "Rebuilt". When Customer gets it Back,

it is Still Bad or even Worse than Before. Then Customer (You) is Pissed as you now have a "Rebuild" Bill and your Machine is Still Not Running, and

You & Repairman Still Don't Know What's Wrong.

B --- Or, They usually Damage Magnet-Shell, Armature, and Fragile Tachometer Armature because they do Not Know how to take Motor Apart. They then Screw-Around with Motor a While, then they Give-Up, Throw All Parts Loose & Damaged in a Box, and return the Whole Mess to Customer. Then Customer sends it to Me for a "Trade-In", as

I Sell Most Motors on an Exchange Basis. I have been Repairing Strippit's for Over 35 Years and I have seen "A" & "B" above, Over & Over Again!

If Anyone has Opened-Up Motor & Tried to "Repair It", I No Longer Give Any Credit!

Below, is a Photo of 1 such Servo Motor, Just as I Received It from a Customer,

who used a "Local" Motor Shop to "Try to Rebuild".

--- Motor Arrived with Shaft Sticking Out of Box.

--- All Parts were Loose Inside Box.

--- Tach Ring is Broken in to Pieces.

--- Wire was Stripped-Off Motor Armature & Commutator, Damaging Both.

--- Tach Armature had it's Wire Stripped-Off, and is Broken into 2 pieces,

--- Many Parts are Missing.

So, For those of You who are a Little Slow on the Up-Take Here,

Do NOT Take Your Servo Motor Apart,

You Will Damage It !!!

Do NOT Take Your Servo Motor To The "Local" Motor Shop,

They Will Damage It Even More!!!

Because of this Problem, I started Rebuilding Servo Motors for Strippit Machines 35+ Years ago. All My Servo Motors are Washed, Armatures are Completely Rewound, Magnet Shells Replaced if Necessary, Brush Holder Problems Repaired, Tach Ring

and Tach Armatures Repaired, New Brushes Installed, New Bearings Installed, and any other Problems Repaired.

And Finally,

Every One of My Servo Motors are Run on One of My Strippit CNC Punch Machines,

and Tested for Proper Operation, Tuning, and Accel & Decel Characteristics.

No one Else in the World Does This, Servo Motor Testing on a Real Strippit Machine,

so We & You Know that it is a Good Motor that will Perform to Spec on Your Machine.

Motor is then Painted & Boxed-Up after this Final Machine Testing,

so we can Just Pull-It off the Shelf for Quick Overnight Shipping.

6 --- Resolver Feedback Packages and Couplings Eventually Wear-Out and Fail.

Cables going to the Feedback Package can also Fail.

This Loss of Position Feedback can Then cause Axis to Run-Away and Crash into the End of Axis Travel, which can cause both Mechanical Damage and Heat Damage

to Motor from being in a "Stalled" Condition.

If you see occasional Axis "Jumping Position" this can be a Warning Sign

that Resolver Feedback Package or Cables are Wearing out.

Fix or Replace Now to Prevent More Problems!

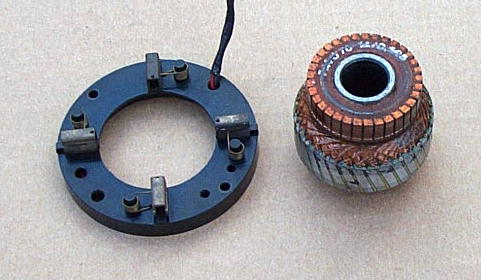

#17546-000

Resolver Feedback Package

and

#17648-000

Resolver Coupling

We Keep Both

of these

Parts In-Stock.

To Recap, We Stock Strippit;

--- D.C. Servo Motors

--- Do Servo Motor Testing & Rebuilding

--- Motor Brushes

--- Brush Caps

--- Tachometer Armatures

--- Tachometer Rings

--- Tachometer Brushes

--- Resolver Feedback Packages

--- Feedback Cables

--- Resolver Coupling

--- Servo Motor Electronic Drives

--- Servo Drive Electronic Repair Parts

--- Servo Drive Electronic Testing

There is Much More

Servo-Drive & Servo-Motor Information on Our

Web-Pages, Go There!

Above is a Servo Motor, as I received it,

after a "Local Shop" tried to Rebuilt it.

It's All Junk now, So Customer Got to Buy a New Motor from me.