Strippit & General Electric Servo Drive Repairs

Machine Technologies Specializes in HECC80 Control Strippit Machines,

and

Provides Servo Parts & Servo Board Repairs on Other CNC Machines Tools

that Used

General Electric Hi-Ack Model 2 & Model 3 Servo Drives Systems.

This Page will Show More of the

Parts & Common Failures & Fixes for these Servo Drive Systems.

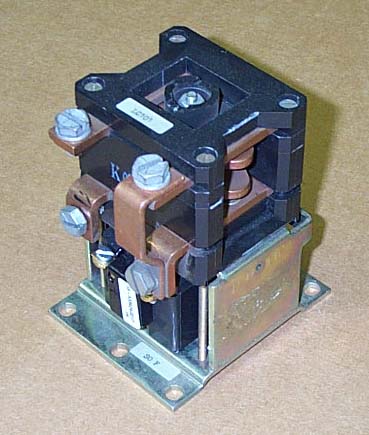

SERVO CONTACTOR, Comes in 2 Versions

Original 90-Volt type Contactor were used in All Model 2 Servo Systems. Strippit #22591-000. Depending on year

Servo System was made, there was a external Back-EMF

Diode across coil and 2nd Diode that fed voltage to coil.

Early Versions did Not have 2nd Diode. There was also a

External-Switch used to pull-in the Next contactor in

Servo System, in a Daisy-Chain way.

90-Volt Contactor also used in Early Model 3 (NOT 3A)

Servo Systems with External Voltage-Dropping Resistor,

so it could withstand higher 150 voltage.

Model 3A Servo Systems used Special 175 High-Voltage contactor for higher 150 volt system. They had the 2 Diodes Molded-Inside Coil, were Stamped

175 Volt on Side of Coil, did Not have external resistor,

and did Not (usually) have or use External-Switch.

Strippit #22803-000.

These 2 Types of Contactors are NOT Interchangeable!

There is 1 Contactor on Each Servo Drive Axis, so typical

Strippit Machine would have 3, 1 for X, Y, and T Axis.

Contactors sometimes Overheat and Burn-Out their Coils,

in Hot Shops in Summer. With Coil Burned-Out,

Contactor will No-Longer Close. As Control does Not

Know Contactor is Open, there will be No Error Message

at Machine & Control Turn-On. As there is No Power

going to Servo Motors, you can grab X & Y Ballscrews and Turn them by Hand, which Verity's No Power to Motors.

You then get "Excess Error" when you try to Move-Axis

as Motors have No-Power and can Not Move Axis.

A Good 90 Volt Contactor Coil Measures about 300 Ohms,

a Burned Out "Open" Coil will Measure Millions of Ohms.

Note, you can Not OHM-Out 175 Volt Contactor Coils

because of Internal Blocking-Diodes.

We Stock Replacement Contactors!

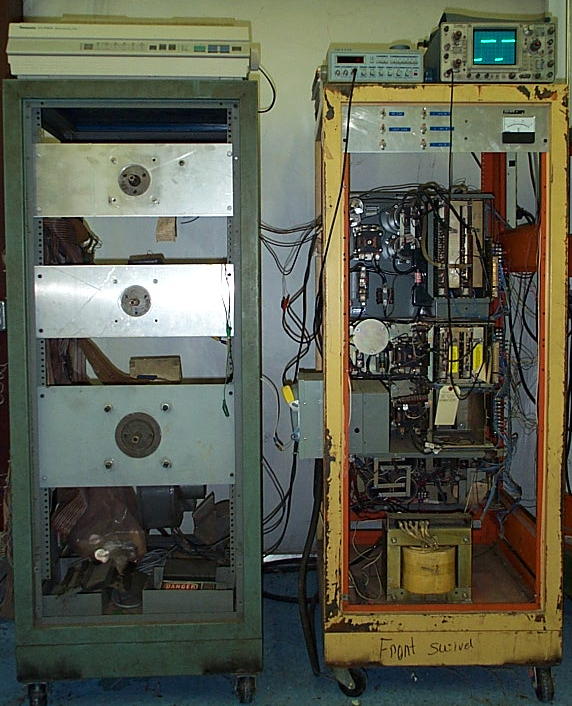

The above Photo shows 3 more Parts of the Servo System that are of interest;

1 --- PWMR2 / PWMR3 Board on the Right.

This Board has been Updated by Machine Technologies with New Capacitors,

New MVR-Relay, and a Green-LED Light to show when the Relay is Pulled-In.

2 --- Servo Power Supply Rectifiers, the 5 Blocks with the 4 Wires coming out of Each Block.

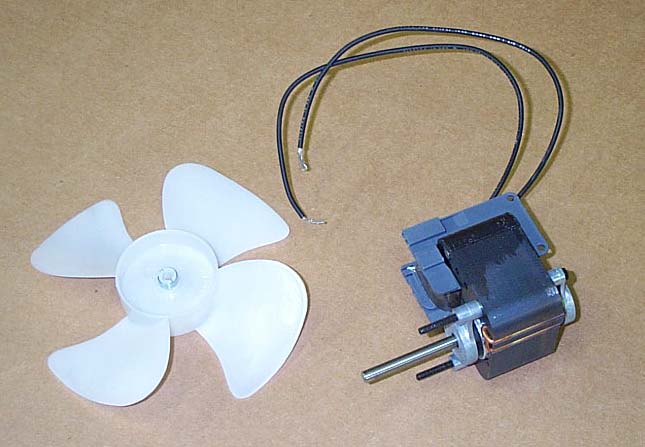

3 --- Servo Cooling Fan & Motor

The PWMR2 & PWMR3 BOARDS are just Different Versions of the Same Circuit Board, and are Usually Interchangeable. These Boards often become Intermittent in Old Age, causing Problems such as "Servo Down" for No Apparent Reason. We Wet-Wash, Repair, and Update these Boards, Adding a Hi-Quality Relay with a Green LED-Light so that you know if the MVR-Relay is Pulled-In or Not. This all Greatly Improves Reliability and Ease of Trouble-Shooting, as it helps in telling you of Internal Servo Inhibit-Faults.

Servo Rectifiers & Servo Rectifier Retrofit Kit

Another Common Problem is Shorting-Out of Rectifiers for the Main Servo-Drive Power Supply.

Rectifiers Short-Out and 20 or 24 Wires to them Burn-To-Pieces unless Servo Fuses Blow in Time.

Makes a Lot of Smoke and a Melted-Rats-Nest of Many Wires. There are 5 Rectifier Blocks with 4 Wires each in a Single-Phase System like a Strippit FC750, FC1000, or FC1000/2.

Strippit FC1250's have a 3-Phase System with 6 Rectifier Blocks.

Rectifiers are Hard to Get At, Replacing Rectifiers and many Burnt Wires is a Pain in the Ass.

To Solve this Problem, we have our SERVO RECTIFIER RETROFIT KIT.

We remove all Old Rectifiers and Rats-Nest of Burnt Wires going to them.

Bolt the Kit's Heatsink & Rectifier Assembly to where ever it is Convenient for You.

Run Transformer's 2 (or 3 wires in a 3-phase system) to our Hi-Current Rectifier Block.

Run 2 Rectifier Output Wires to Servo Chassis Power & Ground Studs. And You are Done!

This is Much Easier than Changing All Rectifiers & Wires the Old Way.

And if our Hi-Current Rectifier ever Fails (we have lost 2 in last 10 years), You can Now Easily

Change it in only 5 Minutes! 2 Photos below show Our Rectifier Kit Retrofit Kit, and a

Installation in one of our Customer's FC750 Machine.

SERVO COOLING FAN

The Servo Cooling Fan Motor, used on All Model 2, 3, and 3A Servo Systems, Typically Locks-Up in old age, then

Servo Overheats and Shuts-Down with a

"Servo Down" Message.

We Stock a New Replacement Fan and

Fan-Motor to Repair this Problem.

Our Motor is More Powerful than Original

to provide Better Cooling

And it has Ball Bearings to provide Longer Life than Plain Bronze-Bushings

of the Original Type Motor.

This page was last updated on: 1/15/2026

This Page is a Continuation of our

"SERVO DRIVES" Page.

Be Sure to

Click-On Buttons Below

to Read those SERVO Pages Also!

We Stock & Repair All of the Following Servo Parts!

STRIPPIT & General Electric

SERVO-DRIVE BOARD TESTING & REPAIR!

Unlike Others, We Actually Test and Repair

Our Strippit & G.E. Servo Drive Boards.

We have Custom-Built Testing Rigs,

as well as 4 Strippit CNC Machines,

Just to Test & Prove-Out Your Servo Boards in a Actual Strippit CNC Machine.

What could be a Better Test of Your Boards?

We Are The ONLY Company That Does This!

Call for Board Testing Information

and Shipping Instructions.

Remember,

We Need Your

Machine Model-Number

AND

Machine Serial-Number

AND

Strippit Part-Number

of Parts you are looking for

if Possible!

Machine Model # & Serial #

are on

Metal ID-Plate

on Side or Back of Your Machine

Get These

2 Numbers

BEFORE You Call!

PHONE: 704-

233-5229

90 Volt Contactor

Strippit #22591-000

G.E. #44A399668-001

G.E. (old) #IC4482CTRA701BA404A1

150 Volt Contactor (Labled 175 Volt)

Strippit #22806-000

G.E. #44A399668-004

G.E. (old) #IC4482CTRA701BA415XO

Servo Filter Capacitors

Each Servo System has about 8 to 12 of these Large Capacitors to Smooth Pulsing-DC from Rectifiers, to make DC-Power suitable for Servo Drives to use. These Capacitors are quite Reliable, and while they do Dry-Out and lose Capacitance in Old Age, the Main Failure Mode is Screw Terminal Arcing on Top. Screws and Buss Bars connecting Capacitors loosen over Time from Machine Vibration and the Natural Cooling & Heating Cycles in your Shop.

As they Loosen, a small Air-Gap Forms, an Electrical Arc Forms, and Terminal and Buss Bars

will quickly be Burnt Up. Repair requires replacing Damaged Capacitor and Buss Bars.

This is Easily Prevented if, once a Year, you or your Technician, Shuts Off All AC Power,

and just Tightens All Screws in the Servo Drives.

Model 2 Servo Drive 90-Volt Capacitors

Strippit #18350-000, G.E. #44A397964N10, Old G.E. #44A399668-001

Model 3 and 3A Servo Drive 150-Volt Capacitors

Strippit # ??? , G.E. #259A9078-M74

This Insolent Male Fox

and His Vixon

Raised 6 Pups under our Back Porch