Strippit CNC Punch Machine

Clutch & Brake

Timing-Hub Retrofit

For Years & Years, Strippit used a Disk-Hub and Timing-Disk that were Bolted on to

End of Crankshaft to Hold Magnets for Sensors used for Punch Press-Drive Timing.

And for Years & Years, Strippit had Problems with Bolts Shearing-Off, Timing-Disks & Hubs getting Loose, Sensors & Magnets Broken and Destroyed, and Finally the End of Crankshaft becoming Ruined by Repeated Attempts at Re-Drilling & Re-Tapping New Bolt Holes.

I would Complain to Strippit Engineering about this Problem and they would Just show me

Their Calculations that showed that Mounting-Bolts were Strong Enough for the Job.

The Strippit Mechanical Engineers could Not Understand that Gripping a Disk, Only in the Middle with a Very Small Radius Bolt-Pattern, was Obviously Not Sufficient to Hold it

Securely from Start & Stopping Shock of Millions and Millions of Punch-Cycles, and the

Metal-Punching Shock-Waves that Traveled-Up Ram to Crankshaft from Punch-Tool.

Engineering Fiddled with Different Hubs, Disks, and Bolt Patterns for a few more years

until they Gave-Up. Problem was finally Fixed by Lengthening Crankshaft and Installing a

Keyed Nylon-Hub on Crankshaft, with Metal-Tape Patches Stuck-On Hub for Timing Points,

that were then Sensed by Proximity Sensors, and this setup worked well.

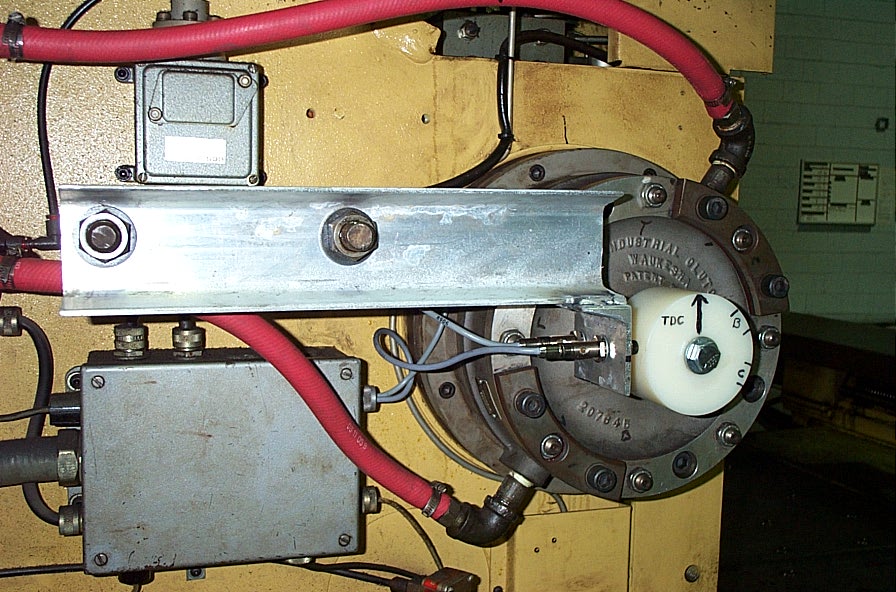

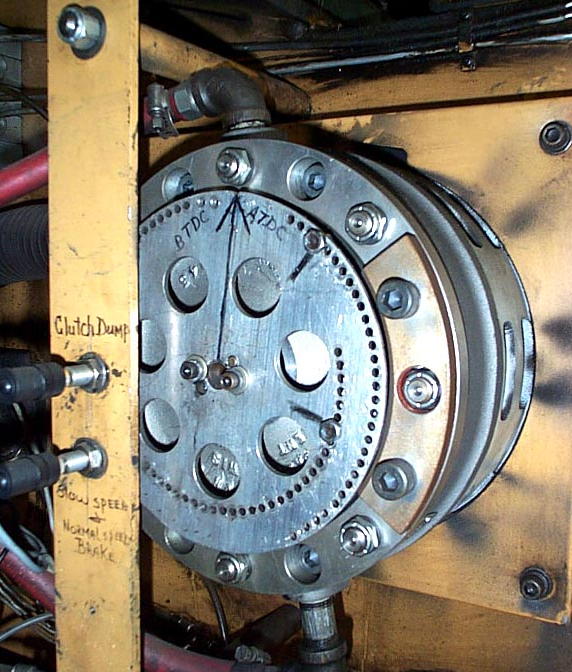

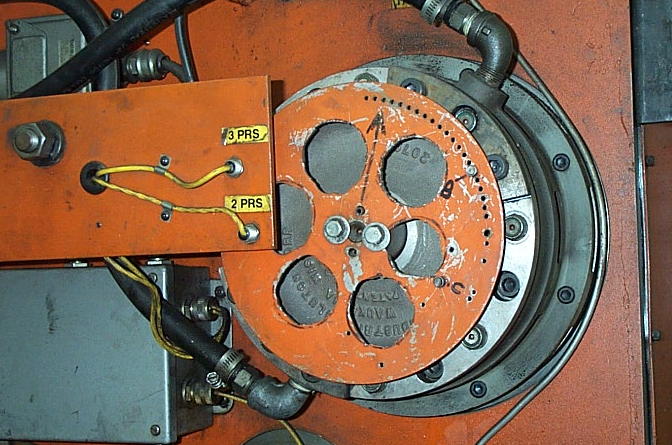

Photos of Old Timing Disks, and some Disks that were Lightened by Customers

which does help with this Bolt Breakage Problem.

There was also a Second Problem Self-Inflected by Knuckle-Headed Customers.

When Lube Tank would get Low, Machine would Stop with a "Lube Failure" and "All Hold".

Operator would then Look Around, and would Grab the First Oil-Like Substance he found.

This was Usually a Bucket of Hydraulic Fluid that most Shops have laying around.

He would then Dump this Hydraulic Fluid In Lube Tank, instead of the Correct

Mobil DTE "Heavy" ISO 100 Weight Lubrication Oil and go Back to Running Machine.

Hydraulic Fluid is a Very Thin Fluid made for Transmitting Power, NOT for Lubrication!

This Thin Hydraulic Fluid would cause Bronze Thrust Bearings that Control Crankshaft End-Play Movement to Wear. Now Crankshaft could Move Back and Forth, and Magnets on Timing Disk

on End of Crankshaft could now Crash into Sensors Destroying Both Magnets & Sensors.

On most Machines, it is Not Practical or Cost Effective to Repair by Disassembling Machine, Pressing-Out Old Worn Bronze Bearings, and Shrink-In and Hone-to-Size New Bearings.

As Sensors were Mounted at Side of Nylon Timing Hub Design, and Not at End like

Magnet Disk Design, Minor Crankshaft Back and Forth Movements had No Effect at all and Eliminated Sensor Crashes. So Nylon Hub Design Fixed Both the Bolt Breakage Problem

and Crashing-Sensor Crankshaft-Endplay Problem.

Photo Below of a Strippit FC1250/30/1500 Machine that had Both Problems,

shown with a Nylon Hub Retrofit that I installed, which has worked very well for years now.

However, some Machines that had End of Crankshaft Ruined by Holes and Broken Bolts

also did Not have enough Crankshaft Length to Mount a Nylon Hub Retrofit.

For these Machines, we have come up with another Retrofit Fix.

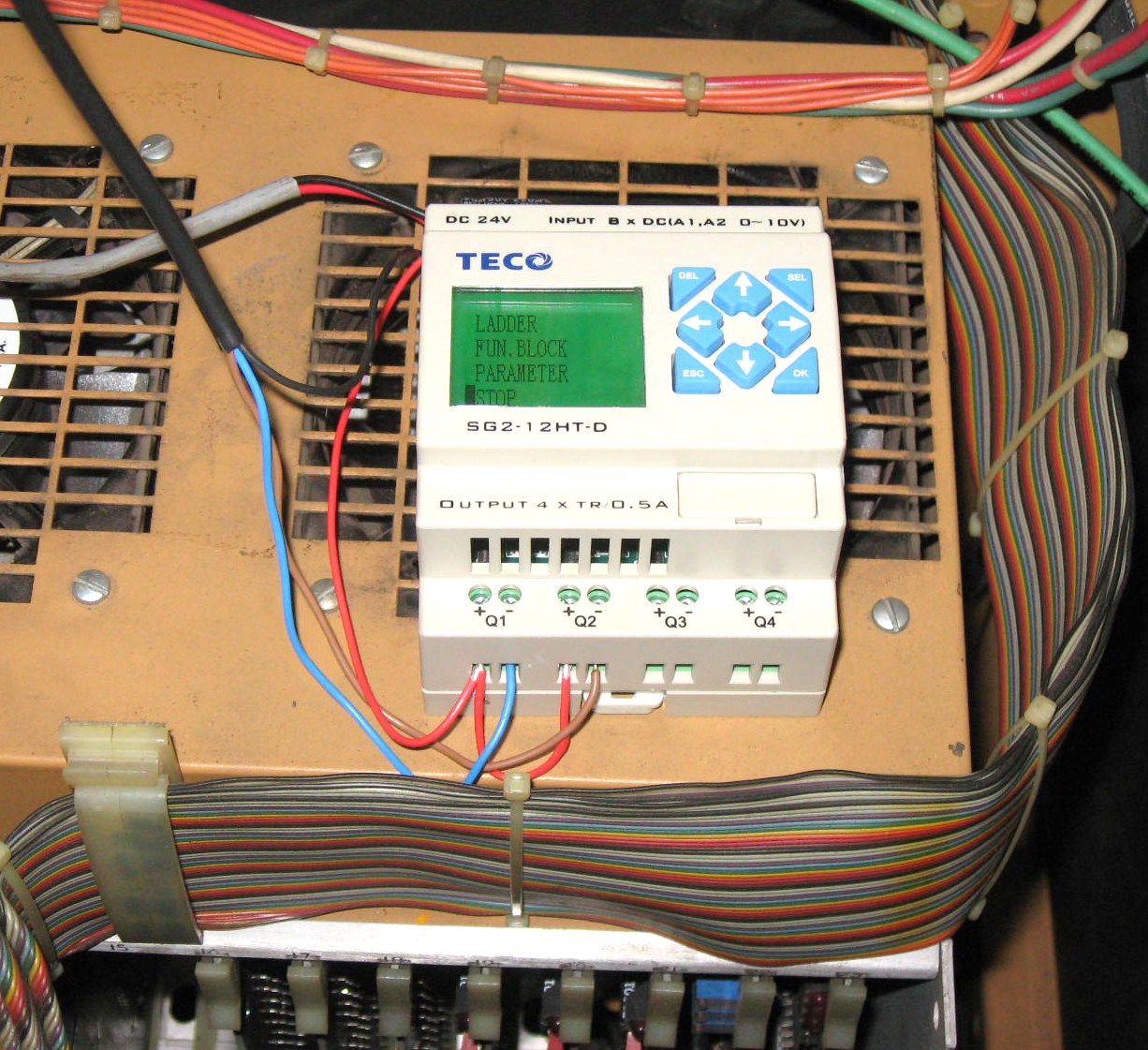

When Punching, we Pick-Up the "Ram-Up" Signal and send it to a PLC

( Programmable Logic Controller ). When PLC Sees the Loss of "Ram-Up" it Starts

2 Programmable Timers, 1 for "Clutch-Off" and the other for "Brake-On". PLC Timers

send Timing Pulses Out to take the place of Original Clutch-Dump and Brake-On Sensors.

Both Timers are Adjustable to make the Ram Stop at Top-Dead-Center as it should.

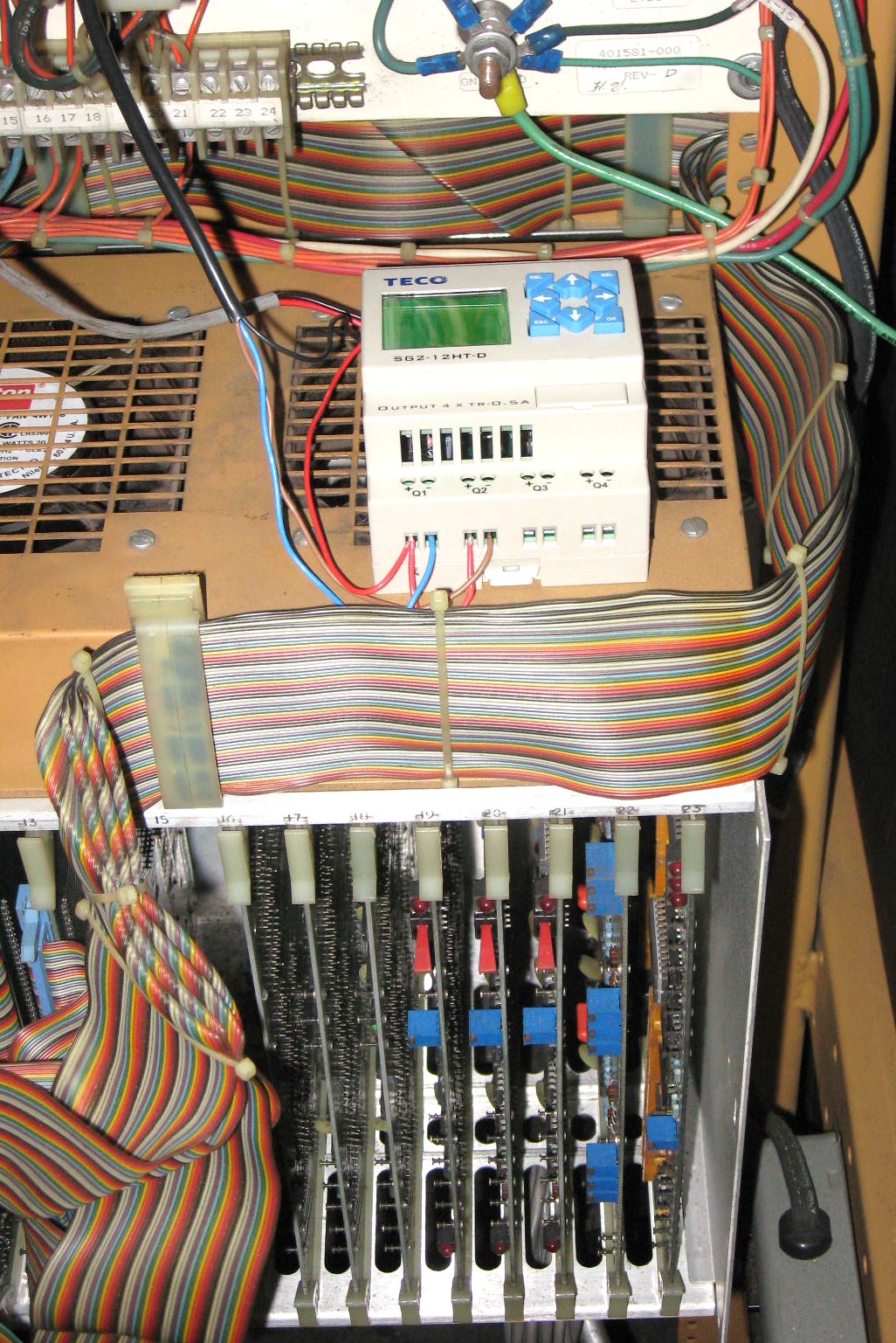

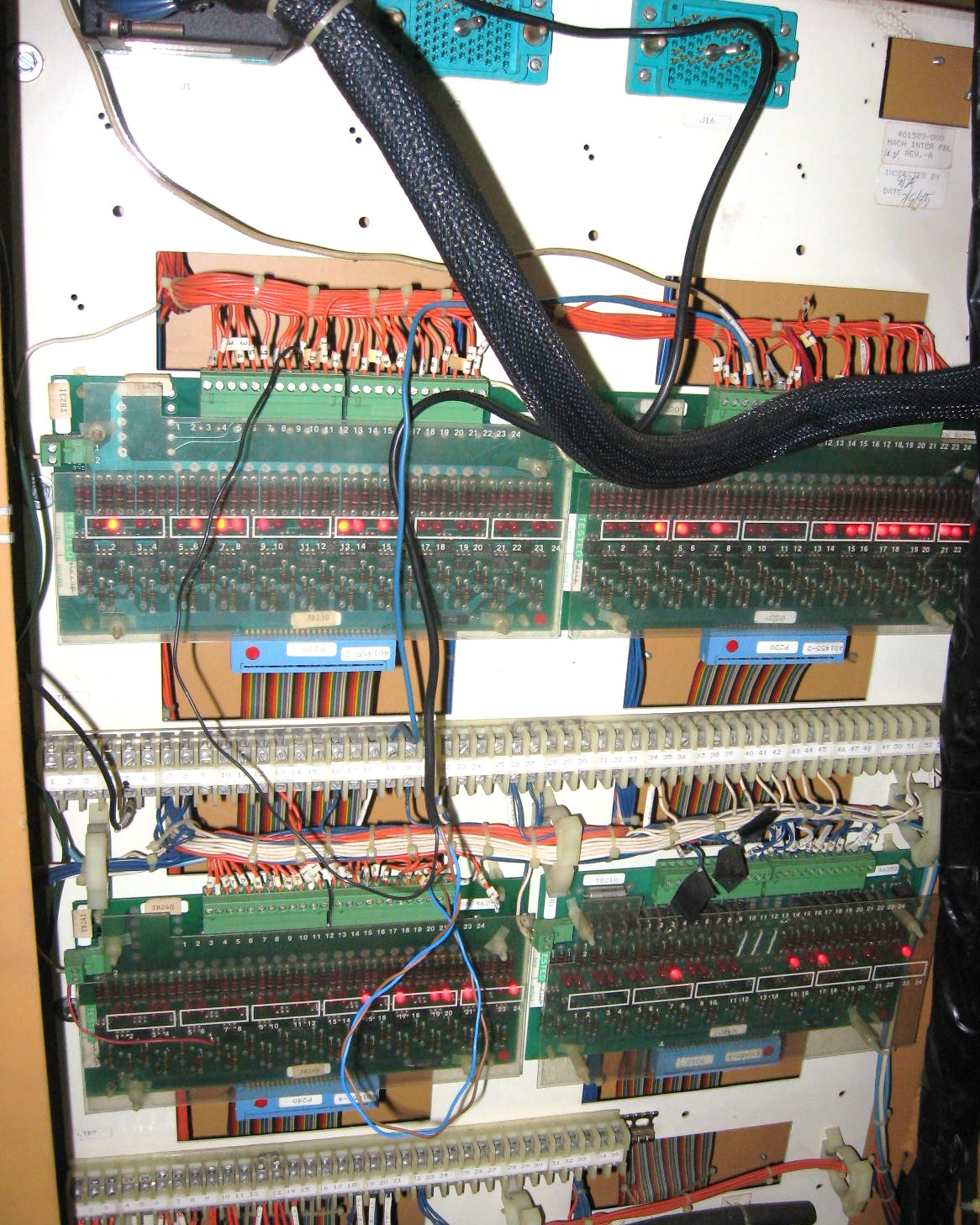

Once I had done the Engineering and Programming, the Installation was Easy with only

5 Wires to Hook-Up to HECC80 Control, Power & Ground, Ram-Up Signal-In, Clutch-Dump,

and Brake-On Signals-Out. 3 Photos of this PLC Retrofit are shown Below.

After PLC Retrofit, we No Longer Need or Use Timing-Hub, Timing-Disk, Timing Sensors,

Magnets, Sensor Brackets, and All these Parts were Removed from Machine.

Retrofit has been done to 3 Machines so far, a HECC80 Control FC1250/30/1500 and

2 HECC80 Control FC1000/3 Machines, and all have Run-OK with No Problems.

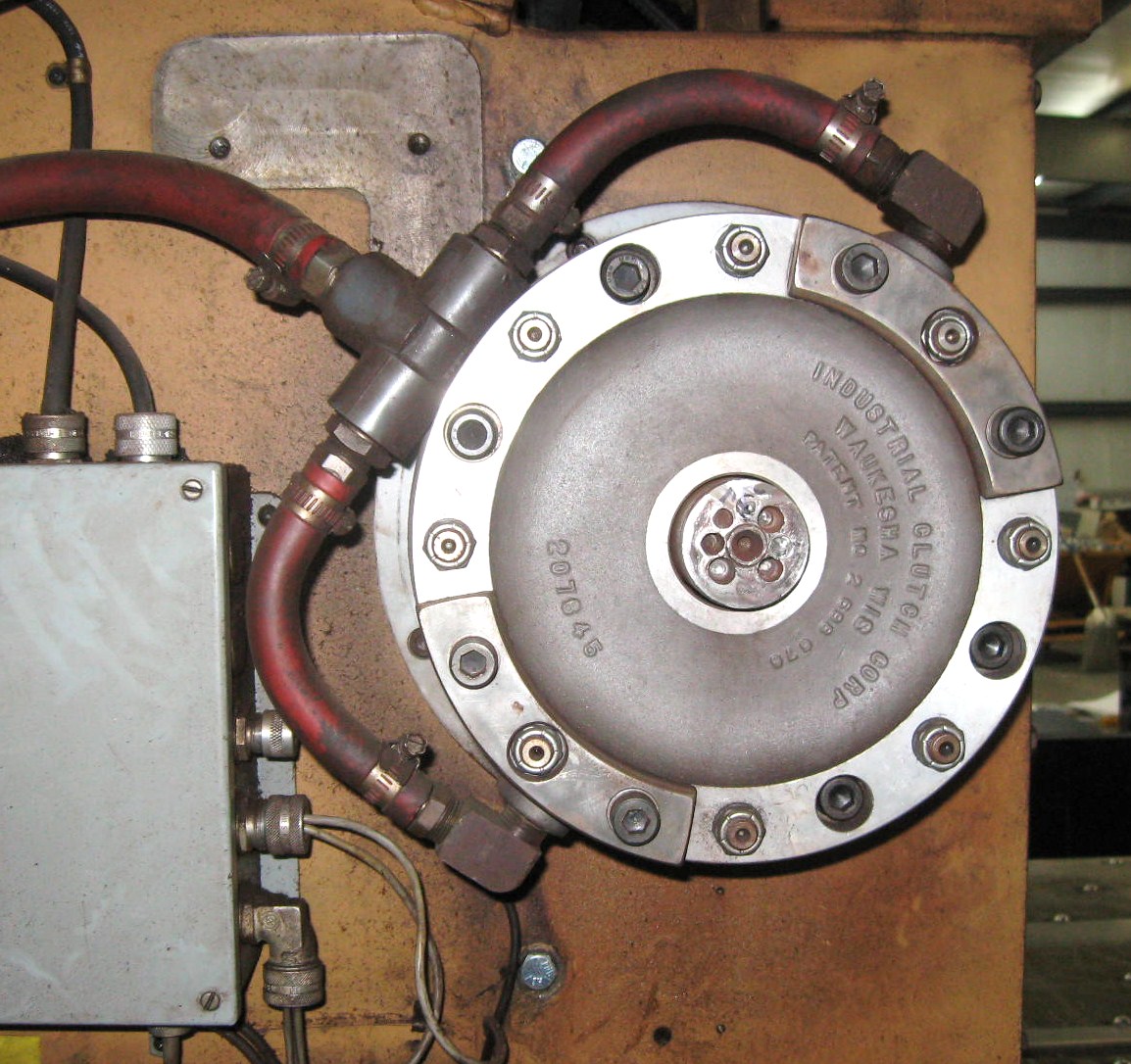

Final Photo Below shows FC1250/30/1500 Machine with all Old Timing Parts Removed

and Machine Runs Great! Notice all the Old Stripped-Out Holes in End of Crankshaft.

This page was last updated: June 4, 2025