Mechanical & Electronic Repair Parts For

Strippit NC & CNC Turret Punch Press Machines

Below are Some of the Repair Parts

We Stock to Keep Your Strippit Machine Up and Running!

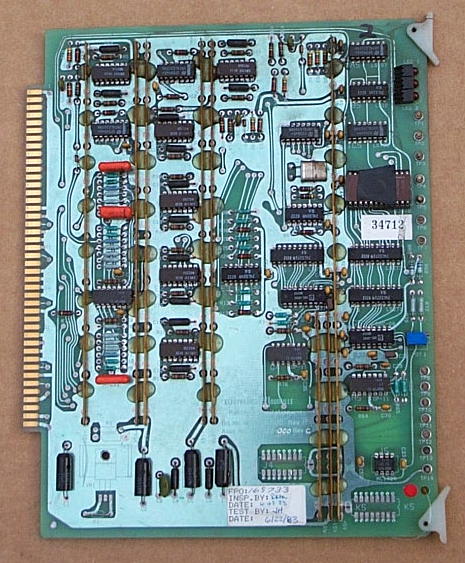

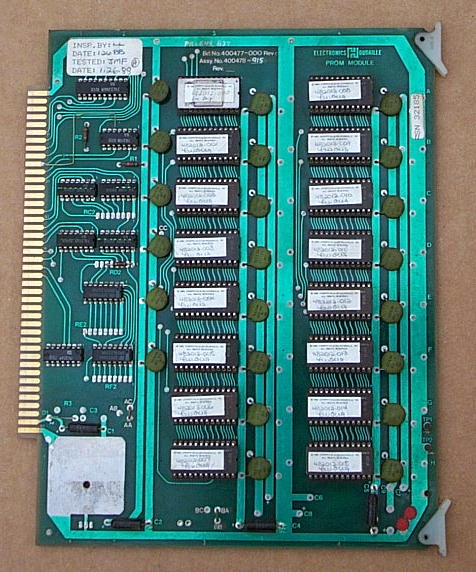

Strippit Houdaille HECC80 CNC Control

Circuit Boards and Parts are Our Speciality!

Sales, Exchanges, Testing, and Repairs of

Strippit HECC80 Circuit Boards, Servo Boards,

Self-Scan Displays, CRT Displays, Keypads,

Keyboards, Power-Supplies, Panel Switches,

and All Other HECC80 CNC Control Parts!

Servo Motors

X, Y, & T Axis Servo Motors are Stocked

Motor Parts are also Stocked;

--- Motor Brushes

--- Tachometers

--- Tach-Brushes

--- Resolver Feedback Packages

--- Resolver Couplings

--- Cables & Connectors

Press-Drive Air-Clutch & Air-Brake Parts

--- Clutch Assemblies --- Brake Assemblies

--- Splin Hubs  --- Seal Kits

--- Seal Kits

--- Friction Disks  --- Springs

--- Springs

--- Clutch Poppits  --- Pistons

--- Pistons

--- QRV Rotary Valves

--- Many Other New & Rebuilt & Used

Clutch and Brake Repair Parts

Note! New Clutch & Brake Units have

LONG Production Lead Times of 4 to 6 Months!

If your Clutch or Brake is Wearing-Out and

Needs Replacement in the Future,

You Need to Order-It NOW,

Before You Really Need it and Put 1 On Your Shelf!

I Normally Sell-Out of Brake Units Before I Even Receive Them!

Switches, Sensors,

Mac Air Valves,

Ballscrews,

Turret Parts,

Lube System Parts,

Tool Lifters.

Workclamp No-Punch Sensors, Limit Switches, Strip-Sensor Retro's,

Mac Pneumatic Valves,

5 and 70 psi Air Switches,

Lifter Studs, Tool Lifters, Springs, Tool Holders,

Oil Seals, Lube Pumps, Filters, Ballscrews, Bearings, Air Cylinders

and Many Other

Repair Parts Too Numerous to List. Call!

Call 704-

233-5229

for Strippit Part Pricing and Availability

Remember, We NEED Your

Strippit Machine Model-Number

and

Machine Serial-Number

Emailing us a Good Photo of I.D.-Plate

will Provide these Numbers!

and the

Strippit Part-Number you need,

if Possible

Of The Repair Parts You Are Looking For!

Phone: 704-

233-5229

Machine Technologies Co.

This page was last updated: January 15, 2026

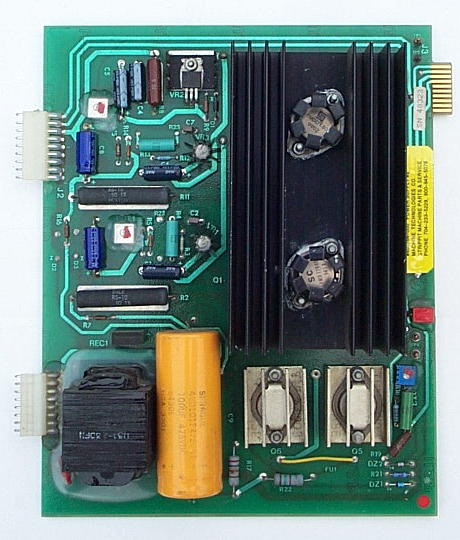

Strippit

&

General Electric

Hi-Ack

Servo Drive

Boards In-Stock!

Sales, Exchanges, Testing and

Repair of

Servo Drive Boards

used in Strippit

and Other

CNC Machines.

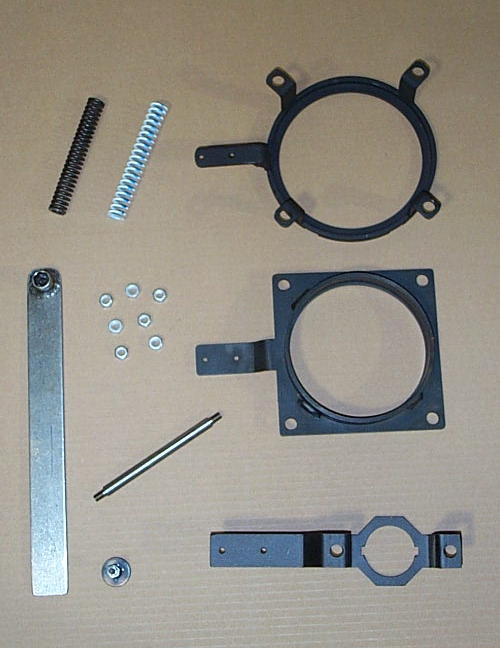

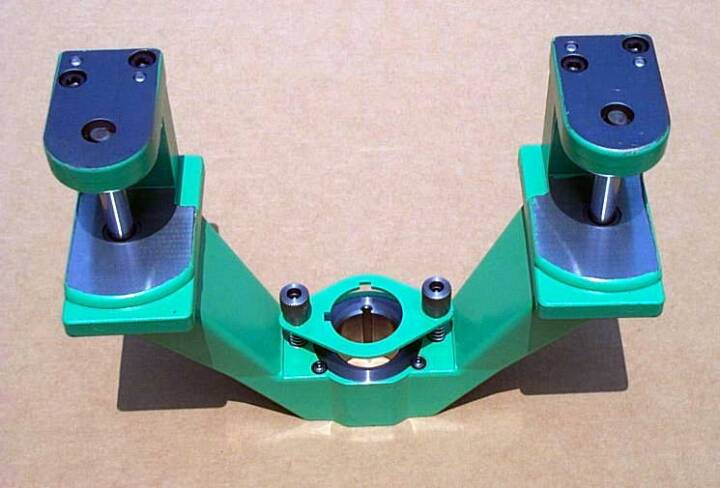

Upper Turret Tool-Station Repair Parts for FC750, FC750/2, FC1000/1, FC1000/2, FC1000/3, FC1250/30/1500, FC1250/45

--- #17591-000 Lifter Spring

--- Heavy-Duty (White & Blue) Lifter Spring,

Our Part #17591-HD, Used on Big 3 1/2"

Stations Only. These Provide

Much Better & Faster Stripping-Action

--- #100245-000 3 1/2" Tool Lifter

--- #17590-000 Stud-Nut, Always Replace

Lower Stud-Nut when Replacing Studs!!!

If you Strip-Out Thin-Original Type, you have

No Access to Remove it Under the Turret!

--- #200285-000 2x2 Notch-Tool Lifter

Usually for Station #1 only

--- #100726-000 Lifter Stud, Uses 2 Nuts

--- #17351-000 Strip-Target, 1 is on each Lifter

--- #100811-000 1 1/4" Tool Lifter

--- And Weld a 7/16" 6-Point Socket to a 1" x 10" x 1/8" Strip of Steel

(Like in the Picture Above) to make Yourself a Tool to

Remove & Tighten Lower Stud-Nuts Underneath the Upper Turret.

Also use it as a "Feeler Gage" to

Set & Maintain the 1/8" Gap on All Your Strip-Targets!

#17546-000

Resolver Feedback Package

Used on All X, Y, and T Axis

Servo Motors on

All HECC80 CNC Control

Strippit Machines Ever Made.

#17648-000 Resolver Coupling,

Used to Couple Servo Motor to the Resolver Feedback Package.

Worn-Out Resolvers,

Broken Couplings, and

Intermittent Wire Cables are

The Most Common Causes of

X, Y, T Axis "Jumping"

"Excess Error", "Miss-Positioning" and "Running-Away" Problems!

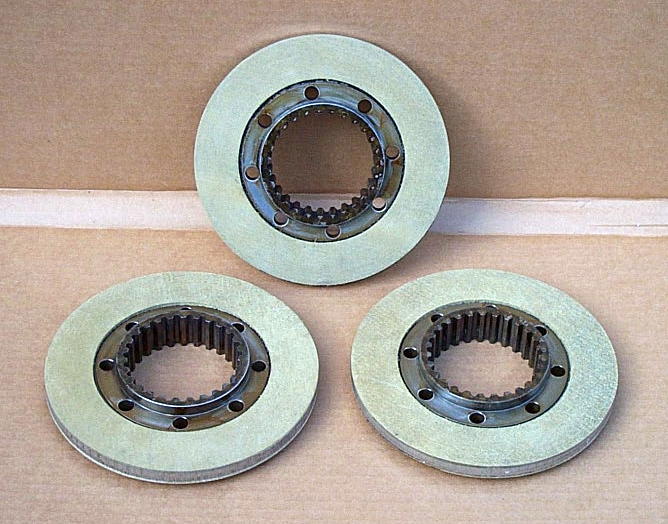

Kevlar-Brake Disks

In the Olden Days, Brake Disks were made with Asbestos, Copper, and Other Materials. These Materials were Discontinued in Early 1980's, and Clutch & Brake Disks have been made with Ceramic Materials ever since.

Problem is, Ceramic Linings are Harder than the Steel & Iron Surfaces in Brake Assemblies. This Causes Disk

to Burrow into the Metal and Destroys Brake Assembly, so that it can Not be Rebuild like they used to be.

To Solve this Problem, We Now Manufacture Our Own 8 Inch Kevlar-Lined Brake Friction Disks.

These Disks are Machined out of Solid 8 Inch Steel Bar Stock, the Internal Splins are Flame-Hardened,

and Finally Kevlar Friction Material is Bonded to the Brake Disk.

The Kevlar Material Will Not "Eat" into the Metal Surfaces of your Brake Assembly, and will Not Wear it out!

These 8 Inch Disks are Exact Replacements for Strippit Part #18075-100, and are for the

Strippit FC750, FC750/2, FC1000, FC1000/2, FC1000/3, FC1250/30/1500 Machines with 1 or 2 Disk Air-Brakes.

Some Brake Rebuilding Notes;

1 -- Do Not put a New Brake or Brake Disk on to a Worn-Out Crankshaft Brake Splin Hub, Replace Hub if Worn!

2 -- Coat Internal-Splins of Disks & External-Splins of Hub with Molykote GN Paste using a Toothbrush.

3 -- Coat all Studs of Drive-Ring & Pressure-Plate with Molykote GN Paste, Do Not get it on to Friction Surfaces!

4 -- Replace Studs if Excessively Worn or Broken. Studs can be Pressed-Out with a Arbor-Press.

5 -- If Drive-Ring & Pressure-Plate surfaces are Worn, Machine them Flat on a Lathe before installing New Disk.

6 -- Depending on Brake Version, there are up to 24 Washers & Spacers, try to put them back in Correct Places!

7 -- Brakes with Stroke-Limiters are Shimmed for a .030 to .050 Inch Gap under Bumpers.

8 -- Stroke-Limiter can be Added if Brake does not have Option, this reduces wear & noise & improves speed.

9 -- Always Replace Seals when Rebuilding Brake, All Air-Brakes use Seal Kit Part #17364-200.

Sensors & Magnets

#18122-000 HECC80-Type Only Sensor, On The Left in The Photo Above.

#17441-000 Magnet with Special Kelps-Nut, Used with Both Type Sensors.

#17792-000 2nd Generation "A-Control" Type Sensor, On the Right in Photo Above.

#17440-000 1st Generation "A-Control" Type Sensor,

Has short 6 inch Wires instead of Cable. Not Shown in Photo above.

These Sensors & Magnets were Used on most Strippit NC & CNC Machines for

Clutch-Dump, Brake-On, Ram-Up, & Tool-Doors, Etc., up to 1987,

When Strippit Changed Over to Using Fanuc Controls & Proximity Sensors.

Note, The 2 Sensor-Types ("A-Control" & "HECC80") are Not Interchangeable!

These Sensor Switches are No Longer Manufactured, and Availability is very Limited!

See Our Sensor Retrofit Webpage

New Workclamps

and Workclamp Repair Parts

--- Complete New Workclamps

--- Clamp Bodies

--- Lower Jaws

--- Upper Jaws

--- Air Cylinders

Many Other

Sensors

and

Switches

are Available.

Call with the

Strippit

or

Manufacturer

Switch-Sensor

Part-Number

You Need.

Grinding Wheels

If you have a

Strippit #85010-000 or #72150-000

Punch & Die Tool Sharpener Machine,

Like Shown at Right, Then you will Need

New #12359-000 Grinding Wheels

from Time to Time.

Strippit Only Sells Crappy Imported Wheels

that have Less Abrasive-Material than the

Original Wheels they Sold Years-Ago.

Strippit's Wheels also use a

Very Poor Binder-Glue so they are

"Soft" and "Wear-Out" Very Fast.

We Now Stock

The Original Grinding Wheels!

If You Want a

Top-Quality Grinding Wheel

for Your Strippit Tool Sharpener,

We Are The Only Source!

This is Strippit Part Number #107727-100 Auto-Index Coupling.

2 are Used (1 on Upper Turret & 1 on Lower Turret)

to Engage A/I Gearboxes for the Auto-Index Turret Stations

on Strippit Machines Built in late 1980's and 1990's.

We have these Special Couplings In-Stock.

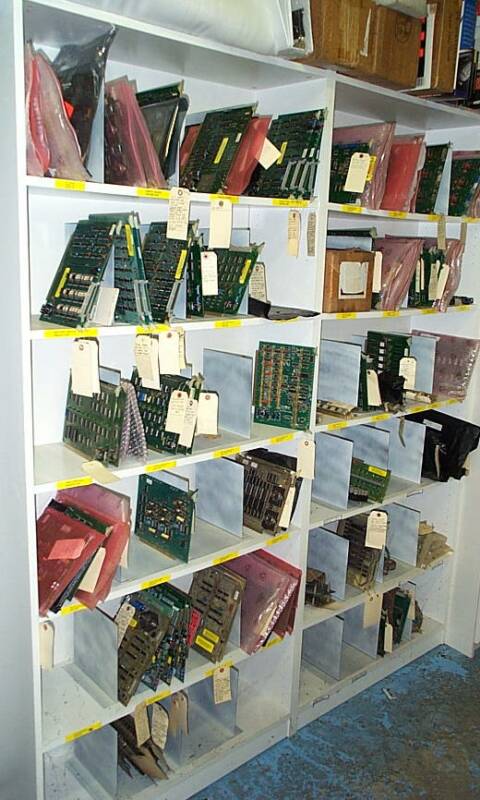

Strippit and G.E. Servo-Drive Boards, On The Shelf, Ready To Ship!

Strippit Houdaille HECC80 Control Boards, On The Shelf, Ready To Ship!

X & Y Axis Re-Zeroing Procedures

Note, Whenever you Un-Bolt or Change a Resolver, Resolver Feedback Package, Ballscrew, Ballscrew Coupling, Servo Motor, Etc, you have Disturbed the Mechanical Relationship

between these Components, and you will Need to "Rezero" your Axis.

X & Y Axis Rezeroing Procedures are Explained on Our "Workclamp" WebPage.

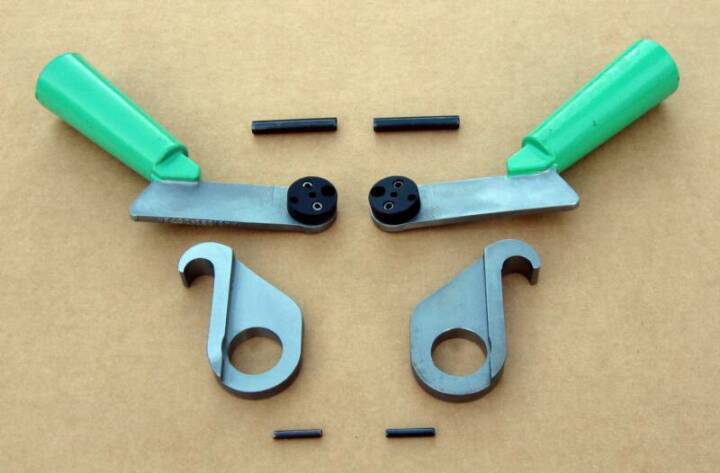

Strippit Single-Station Punch Machine Parts

If you have a Single-Station Strippit Machine - Custom 18/30, Custom 30/30, Super 30/30, Super 30/30-AG, Super 30/40-Mechanical, We Do Stock some Parts for these Machines.

Punch-Head Rebuild Kits

Hook & Handle Locking Kits

1 1/4" & 3 1/2"

Swing-Arm Punch Holders

"Click-On" the Button at The Right

for More Single-Station Strippit Machine Parts and Trouble-Shooting Information!

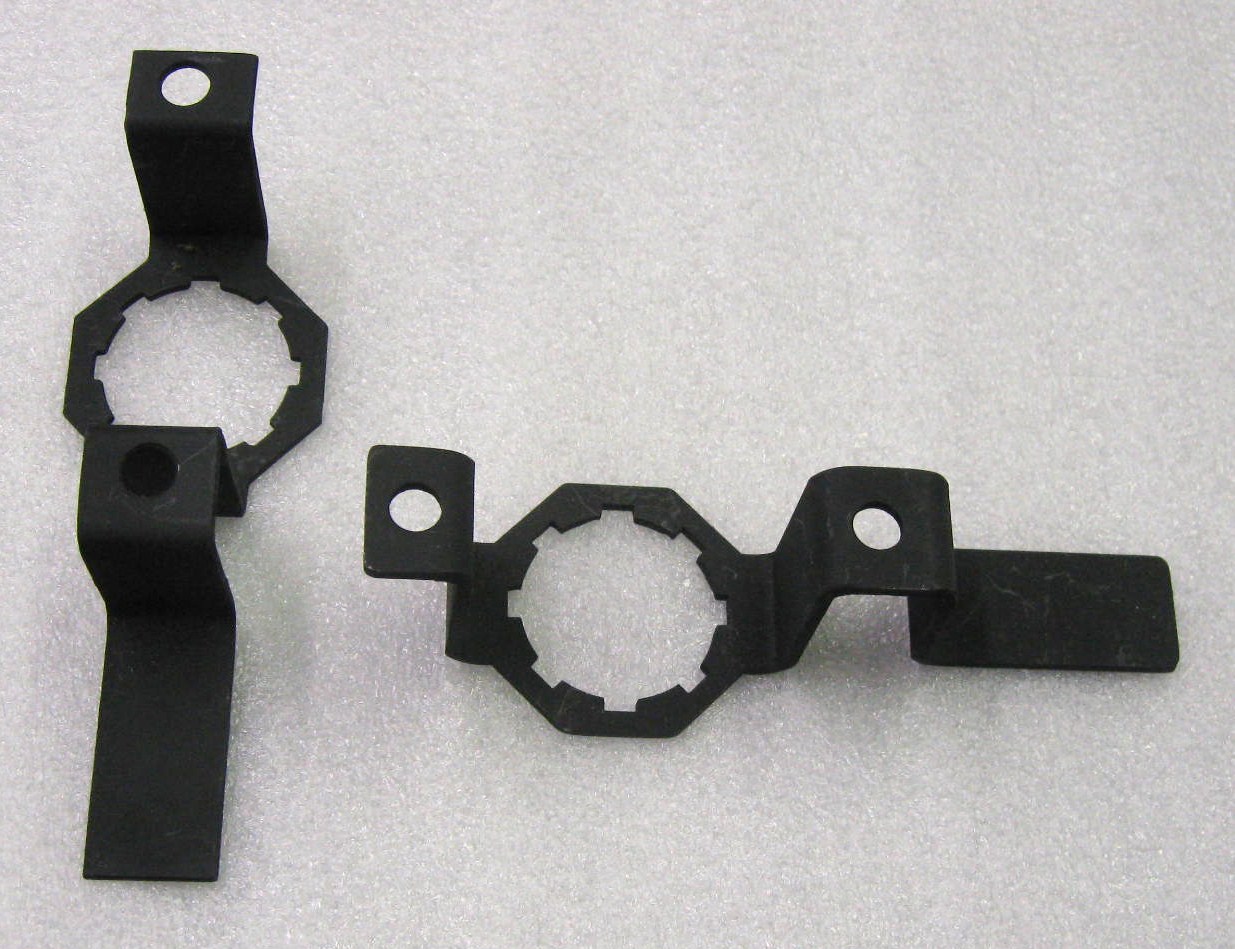

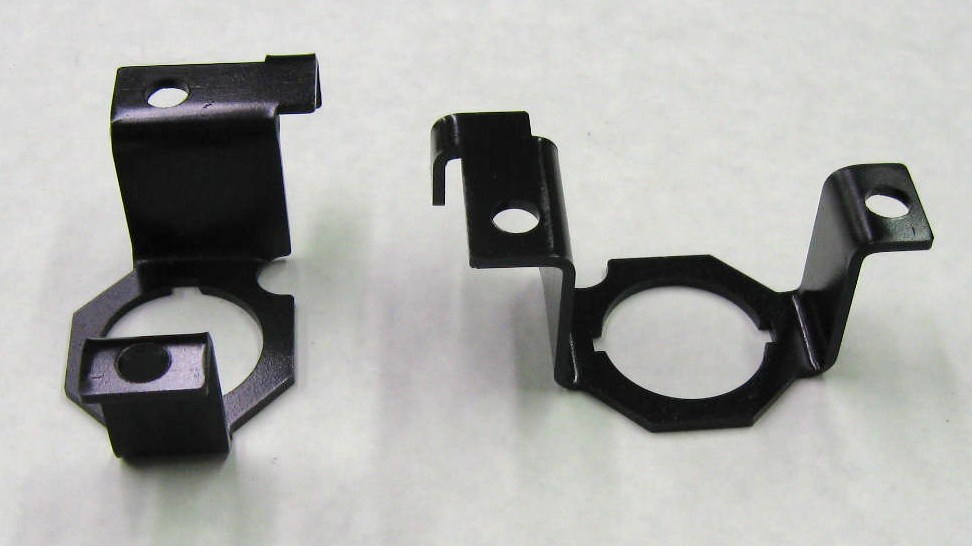

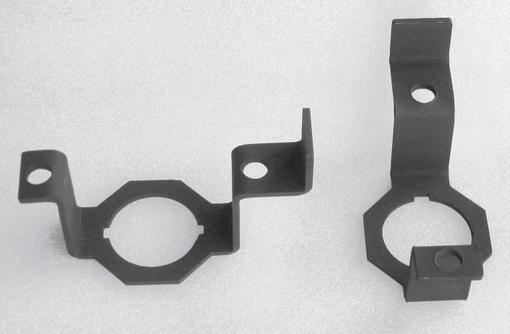

Table Roller-Ball Assemblies

Dozens of these Ball Assemblies were Built-In to Table Tops to Support Sheetmetal Part Blanks, and were used on Strippit CNC Machines from Early 1970's to the Mid 1990's.

Assemblies consist of #17899-000 Clip, #17459-000 Spring, and #17848-000 Roller-Ball.

Early Roller-Balls had a Steel Body, while Later Versions had a Plastic Body,

like in the above Photo. Metal and Plastic Versions both worked equally well.

This Early Assembly "Clips" into a Round Hole & 2 Slots in Table Tops.

We Stock these New Ball Assemblies and also Good Used Assemblies at Half-Price of New.

---------------------------------------------------------------------------------------------

In the Mid-1990's, Strippit Switched to a Better Type of Roller-Ball Assembly

that was Bolted to the Table Top with 2 Small Bolts, making it very Secure

so it would Not Fall-Out of Table, like the Older Type often did.

Strippit also started Offering Brush-Tops instead of Roller-Balls in these Assemblies,

as many feel they do not Scratch or Mark Piece Parts as much as Roller Balls.

We do Not Stock the Later Type of Ball-Assemblies or Brush-Assemblies at this time.

Upper Turret Station Repair Parts

#8681505-019

CAP1000 and CAP1250

1 1/4 Inch

Tool Lifters

We also have a Few #8681505-020

3 1/2 Inch Tool Lifters

"R-Type" #120277-000

1 1/4 Inch Tool Lifter

as used on

630R, 1000R, 1000R2, 1000/R20, 1000XP, 1000XP/20, 1000H20, 1250R, 1250R20, 1250XP20, 1250H20

"S-Type"

#107747-000

1 1/4 Tool Lifter

as used on 1000S, 1000SX, 1000SXP, 1000SXP/30, 1250S, 1250SX, 1250SXP, 1250SXP/30, 1250M, 1250MH, 1250MXP/30, & Fanuc Control FC1000/3

Losing Punching Tonnage?

Lots of Air Leaking Out of Your Air-Clutch?

Then Your Clutch Poppit Valve probably looks

like Poppits Shown on the Right!

Replace it with a New

#17363-300 Clutch Poppit Valve as Shown Below!

There is More Information on Poppits on the

"Common Strippit Problems and Fixes" Webpage!

Liza & Cisco

Catching Snowflakes

on a

Happier Day....